The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

COLD CHAIN

PCM heat exchanger designed for use in refrigerator trucks, micro cold rooms

An unfamiliar PCM application turned up in my LinkedIn feed this week:

“Pluss Advanced Technologies Pvt. Ltd. presents ThermoTab active plates used for both #coldstorages and #transportation applications at India Cold Chain Show 2018”

The post has plenty of hashtags but not much information. I asked Vishnu Sasidharan, right, vice president for new product initiatives at Pluss, for details on the thermoTab Active heat exchanger.

The post has plenty of hashtags but not much information. I asked Vishnu Sasidharan, right, vice president for new product initiatives at Pluss, for details on the thermoTab Active heat exchanger.

Q: Who developed the thermoTab Active heat exchanger and when was it introduced commercially?

A: “The thermoTab Active heat exchangers are being sourced from FIC, Italy, a company which is has been manufacturing heat exchangers for thermal energy storage in refrigerated vehicles since 1951. Pluss has partnered with FIC to offer a complete solution – PCM-filled heat exchangers exclusively in India – introduced commercially in India from September 2017. The partnership leverages FIC & Pluss strength in heat exchanger and material sciences, respectively, to offer solutions for storage, transportation and space cooling/heating.”

Q: What types of PCM are used?

A: “The current standardized offerings are for two categories of temperature; +2 to +8 deg C and -15 to -25 deg C. The plates offered on the basis heat load capacities and the categories under which it falls. For instance, if a customer requires 20kw-Hr of thermal storage capacity for +2 to +8 deg C the number of plates, the customer could refer to the data sheet and choose the combination of thermoTab Active plates based on its capacity. Alternatively, the data sheet also provides with a quick selection of number of thermoTab Active plates based on the volume of the container, insulation thickness and the retention hours required.”

Q: Describe how the heat exchanger functions.

A: “The heat exchanger plates have a refrigerant coil inside. The PCM filled inside the plate remains completely immersed in the PCM solution. During charging or freezing cycle begins when refrigerant is passed through the coil at a temperature lower than the phase change point of PCM. When the temperature in the room starts to rise above the phase change point of the PCM, the surface of the heat exchangers starts to release the energy at a constant temperature, thereby maintaining the temperature of the environment.”

A: “The heat exchanger plates have a refrigerant coil inside. The PCM filled inside the plate remains completely immersed in the PCM solution. During charging or freezing cycle begins when refrigerant is passed through the coil at a temperature lower than the phase change point of PCM. When the temperature in the room starts to rise above the phase change point of the PCM, the surface of the heat exchangers starts to release the energy at a constant temperature, thereby maintaining the temperature of the environment.”

Q: How and when are the PCM panels charged in a refrigerator truck?

A: “The thermoTab Active plates are charged by means of an electric refrigeration system on board the truck. Prior to commencement of the delivery cycle, the truck’s refrigeration system is connected to a three-phase electric source for 8-10 hours. The cost of storing energy by electricity as against active cooling using diesel the savings are substantial. The payback for such system is less than six months.”

Q: How and when are the PCM panels charged in a micro cold room?

A: “In a micro cold room as well the charging takes place similar to a refrigerator truck. However, the operating cost could be further reduced by running the refrigerator unit using solar instead of grid electricity. The thermoTab Active plates provide a unique value proposition for solar-based micro cold rooms by enabling 24/7 uninterrupted cooling without the requirement of an electrochemical battery. Most micro cold rooms operate in areas which do not have access to electricity.”

Q: How does thermoTab Active differ from passive PCM systems used in refrigerator trucks and cold rooms?

A: “Passive PCM systems depend on a centralized freezing unit. This makes the process cumbersome for the user as the PCM modules/cartridges need to be constantly removed from the container to a freezer unit and back. It also results in temperature losses due to exposure to ambient temperature during the loading and unloading of PCM modules.”

Q: How many refrigerator trucks are using the system?

A: “In India over 250 refrigerator trucks are using this system.”

Q: How many micro cold units are using the system?

A: “In India approximately 60 micro cold rooms are using this system. The demand is immense and we believe the application is now beginning to transition from early stage to maturity in terms of market reach.”

PATENTS

Core-shell triggered release systems

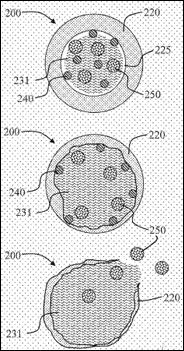

U.S. patent application 20180258340 (applicant Research Triangle Institute, Research Triangle Park, N.C.):

“The present disclosure relates to delivery and release systems, such as core-shell particles. An exemplary composition according to the disclosure can include a carrier element forming an outer shell that defines an inner core. The core can include a reactive agent that is adapted to react with the shell, particularly at an inner interface of the shell with the core materials. The reaction can provide an inside-out degradation of the shell and release of one or more materials therein. The reactive agent may be separated from the shell, such as using a phase change material (PCM). Upon reaching specific environmental conditions, the PCM can change so as the release the reactive agent for reaction with the shell. The systems can be used in various methods to deliver a material to various environments, including underground reservoirs.”

IN BRIEF

• The University of Central Florida was awarded a $360,000 grant from the National Science Foundation last month to develop and commercialize a grid-connected solar storage module. UCF is partnering with battery maker AllCell Technology to develop the system, known as iPV++. The system will use smart inverters and battery management to deliver stable and predictable PV-based solar power for grid-tied applications. AllCell phase change composite material will provide passive thermal management of the system’s lithium-ion battery modules. Dr. Issa Batarseh, UCF electrical engineering professor and the project principal investigator, says use of the material assures “the safety of the battery modules, simplifies the installation and maintenance, and significantly increases lifetime due to temperature control.”

• A prototype cooling vest developed by the Nike Sport Research Lab made its debut at the U.S. Open in Flushing Meadow, N.Y., last week. Scorching heat and high humidity marked the tennis tournament’s later rounds, prompting players to do whatever they could to stay cool. Rafael Nadal, right, was among the players seen wearing the vest courtside. The form-fitting vest features four cooling packs – two in the front and two in the back – to quickly cool down players between sets and before and after matches. Nike declined to answer questions about the vest, but it appears similar to phase change vests already on the market, including products made by TechNiche and Glacier Tek.

• A prototype cooling vest developed by the Nike Sport Research Lab made its debut at the U.S. Open in Flushing Meadow, N.Y., last week. Scorching heat and high humidity marked the tennis tournament’s later rounds, prompting players to do whatever they could to stay cool. Rafael Nadal, right, was among the players seen wearing the vest courtside. The form-fitting vest features four cooling packs – two in the front and two in the back – to quickly cool down players between sets and before and after matches. Nike declined to answer questions about the vest, but it appears similar to phase change vests already on the market, including products made by TechNiche and Glacier Tek.

• Peli BioThermal, the temperature-controlled packaging company, has opened a service center in Indianapolis. The company says the 50,000-square-foot facility will be one of the largest in Peli’s Credo on Demand network.

• Registration is open for the next ARPA-E Energy Innovation Summit, to be held in Denver, Colo., July 8-10, 2019. The 10th annual conference and technology showcase will “bring together experts from different technical disciplines and professional communities to think about America’s energy challenges in new and innovative ways.”

• Australian energy storage startup 1414 Degrees began trading on the Australian Securities Exchange this week after raising $16.3 million AUS as part of its initial public offering. The company’s technology stores electricity as thermal energy by heating an melting containers full of silicon at a fraction of the cost of lithium-ion batteries.

• NETenergy, a Chicago startup that licenses technology developed at the University of Illinois at Chicago, plans to commercialize its hybrid air-conditioning system with funding from the U.S. Department of Energy. The $500,000 grant was awarded to NETenergy’s partner, the National Renewable Energy Laboratory. The International Copper Association and Ingersoll-Rand are commercial partners on the grant, which will provide cash and in-kind matching funds. The technology uses phase change composites to store cold energy, allowing customers to shift A/C production to off-peak hours, when electricity is cheaper.

• Costs for U.S. chemical distributors could rise by nearly $1.3 billion if the United States imposes tariffs on $200 billion worth of goods from China, according to an analysis by John Dunham & Associates. Job losses could top 5,900, the analysis said.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Frontiers in Materials:• Thermoplastic polyurethane blends with thermal energy storage/release capability

From Energies:

• Review of Reactors with Potential Use in Thermochemical Energy Storage in Concentrated Solar Power Plants

From Progress in Computational Fluid Dynamics:

• Towards the simulation of supercooling and convection in phase change materials using a thermal lattice Boltzmann method

From Nanomaterials:

• Palm Kernel Shell Activated Carbon as an Inorganic Framework for Shape-Stabilized Phase Change Material

From Journal of Power Sources:

• A comprehensive review on a passive (phase change materials) and an active (thermoelectric cooler) battery thermal management system and their limitations

From Applied Energy:

• Process integration of thermal energy storage systems – Evaluation methodology and case studies

From Journal of Nanomaterials:

• Effects of Biceramic AlN-SiC Microparticles on the Thermal Properties of Paraffin for Thermal Energy Storage

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,350 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the blog and newsletter of the same name.

More than 1,350 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Poppy O’Neill, Ph.D. student at INSA Lyon and Lucerne University of Applied Sciences and Arts, Lucerne, Switzerland; Igor Stavale Schimicoscki, engineering student at the University of Brasilia, Brazil; Eanest Jebasingh, research scholar at Thiagarajar College of Engineering, Madurai, India; and Jose Miguel Maldonado, researcher engineer at CIRCE Foundation, Lleida, Spain.