The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

BUILDING | CONSTRUCTION

PCMs helped lift Virginia Tech to first place in Solar Decathlon

The Virginia Tech team that won first place in the 2018 Solar Decathlon Middle East credits a good share of its success to the deft use of phase change material donated by Insolcorp LLC of New London, N.C.

FutureHAUS, the lone U.S. entry, topped 13 other finalists and more than 60 total entrants in the competition organized by the U.S. Department of Energy and the United Arab Emirates’ Dubai Electricity & Water Authority. Australia’s University of Wollongong finished second. The finals took place in November in the desert heat of Dubai.

Insolcorp donated 400 square feet of two types of Infinite R PCM mats. Both are salt hydrates, one with a melt point of 21 degrees Celsius, the other a melt point of 22 degrees C. The phase change material acts as a thermal battery, absorbing and releasing thermal energy as it solidifies and melts.

The Virginia Tech team deployed the mats in the plenum of its 900-square-foot solar-powered house. The PCM allowed the team to take advantage of a rule that limited the use of solar energy to 8kw at any one time, with one exception: Unlimited use of solar energy for air conditioning was allowed during daily inspection periods to assure visitor comfort. The PCM mats, solidified during those periods, helped keep the house comfortable at other times. That helped the FutureHAUS achieve the highest score in net energy use, a key metric in the competition.

“Every team struggled with the 8kw limit,” said Joseph Wheeler, right, lead faculty on FutureHAUS and co-director of Virginia Tech’s Center for Design Research. “Typically, during peak energy, you would be generating lots and lots of power, which you could easily charge your batteries with, which you could easily run all your tasks, and you could feed the grid, and build up quite a bit of surplus so that you would remain energy positive throughout the two weeks of competition.

“Every team struggled with the 8kw limit,” said Joseph Wheeler, right, lead faculty on FutureHAUS and co-director of Virginia Tech’s Center for Design Research. “Typically, during peak energy, you would be generating lots and lots of power, which you could easily charge your batteries with, which you could easily run all your tasks, and you could feed the grid, and build up quite a bit of surplus so that you would remain energy positive throughout the two weeks of competition.

“But, since they limited inverter use at any one time to 8kw, it really put a limit to what our energy budget was. We saw phase change as batteries. A massive ton of batteries. … It’s more of a strategy for a competition than it is for a realized situation. But in a realized situation, we know the value of the PCM. Heat energy, cost of power being cheaper at night than during the day where you can charge your systems and load shift. Practically, PCMs make a lot of sense. And we wanted to have the PCMs in this house for practical reasons, not just for competition reasons. …

“In simple terms, we eased the demand for the HVAC every afternoon. It was the hottest time of the day and it was also the time when we were getting less power from the solar panels because the sun was moving down. It was a critical time because we knew that once the sun went down, we had to survive on battery. And we had a limit. They limited every house to 15kw of battery.”

The FutureHAUS team finished in the top three in eight of the competition’s 10 categories: first place in Architecture, House Functioning and Sustainable Transportation; second place in Sustainability and Innovation; and third place in Engineering/Construction, Energy Efficiency and Comfort Conditions.

The FutureHAUS team finished in the top three in eight of the competition’s 10 categories: first place in Architecture, House Functioning and Sustainable Transportation; second place in Sustainability and Innovation; and third place in Engineering/Construction, Energy Efficiency and Comfort Conditions.

The FutureHAUS entry was a two-year university-wide effort. More than 100 Virginia Tech students helped design and build the structure, with help from faculty members in architecture, urban studies, science, engineering and other departments.

The house consists of 18 modular “cartridges” built inside a Virginia Tech research facility. It was first assembled on campus in Blacksburg, Va., last summer. After testing, it was disassembled, shipped to Dubai and then reassembled at the competition site in just two days. It has since been shipped back to Blacksburg, where it will undergo testing to measure its various energy-saving components.

“We now have a system in place where we can collect data and can truly test the performance,” Wheeler said. “We know the PCM worked for us during the competition because we did have some temperature sensors in the ceiling. And so we were able to prove that we were reaching the pre-state when those PCMs were being charged. But we really want to collect a lot more data and look at it in real-world situations.”

PATENTS

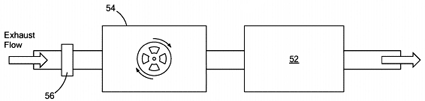

Exhaust system with actuated flow bypass and thermal storage device

U.S. patent application 20190053330 (Watlow Electric Manufacturing Co., St. Lous, Mo.):

“An exhaust system is provided that includes an exhaust aftertreatment unit, first and second exhaust pathway in communication with and upstream of the exhaust aftertreatment unit, a thermally activated flow control device operable in a first and second mode, and a thermal storage device. … The thermal storage device or thermal flywheel [54] may also include a phase change material, an in one form a phase change material that changes phase at a temperature between 180° C. and 45° C.”

Battery pack containing phase change material

U.S. patent application 20190051955 (applicant Consortium de Recherche BRP / Universite de Sherbrooke, Canada):

“A battery pack for a vehicle is presented. The battery pack comprises a plurality of bricks, each brick of the plurality of bricks comprising a phase change material block, a side of the phase change material block defining a plurality of channels, and a plurality of battery cells, each battery cell being disposed at least in part in the phase change material block; and at least one connector for electrically connecting a first one of the plurality of bricks to a second one of the plurality of bricks, the at least one connector being disposed at least partially in one of the plurality of channels.”

IN BRIEF

• PureTemp LLC has joined the Roundtable for Sustainable Palm Oil as an associate member. The nonprofit organization, which has more than 4,000 members worldwide, promotes the growth and use of sustainable oil palm products. In November, RSPO adopted stricter standards for certified sustainable palm oil, including a total ban on deforestation by its members.

• Reda Group‘s new Active Phase temperature-control fabric was on display at the Milan fabric trade show earlier this month. The material uses phase change material to keep body temperature constant when ambient temperature fluctuates. Reda says the material features enhanced breathability and softness and is “easy to clean, even in water.”

• University of Maryland researchers have created a temperature-control fabric that does not rely on phase change material. The fabric changes its insulating properties in response to the environment. In warm and humid conditions, the fabric allows radiant heat to pass through. When conditions become cooler and drier, the fabric reduces the heat that escapes. Two types of synthetic materials in the fabric — one that absorbs water and another other that repels it — are coated with carbon nanotubes. The fibers warp and relax in response to changing humidity, opening and closing pores in the fabric.

• University of Maryland researchers have created a temperature-control fabric that does not rely on phase change material. The fabric changes its insulating properties in response to the environment. In warm and humid conditions, the fabric allows radiant heat to pass through. When conditions become cooler and drier, the fabric reduces the heat that escapes. Two types of synthetic materials in the fabric — one that absorbs water and another other that repels it — are coated with carbon nanotubes. The fibers warp and relax in response to changing humidity, opening and closing pores in the fabric.

• In interviews with Advanced Textiles Source, four entrepreneurs were asked: What do you wish you had known early on when you were first dealing with intellectual property law and patent issues? “Get feedback on why you need a patent,” said Jeremy Wall, founder and CEO of smart-clothing startup Lumenus. “Where else could you spend $20,000?” Said Matt Kolmes, CEO of VOLT Smart Yarns: “Even if you are on a tight budget, file that Provisional application immediately before you show your idea to anyone, or talk about it with anyone.”

• The Marie Sklodowska-Curie Action program is seeking applicants for a one- to two-year research fellowship at the Oslo Metropolitan University. The European Union-funded fellowship will focus on the energy-performance aspects of phase change material in buildings. “In this collaboration,” OsloMet says, “we intend to gain our understanding and explore about the micro-structural aspect to relate the macro-scale behavior at continuum level.” The application deadline is March 7.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Energy Storage Materials:• Self-luminous wood composite for both thermal and light energy storage

• The thermal performances of a refrigerator incorporating a Phase Change Material

From Renewable Energy:

• Enhanced thermal conductivity of palmitic acid/mullite phase change composite with graphite powder for thermal energy storage

• An experimental study on the corrosion sensitivity of metal alloys for usage in PCM thermal energy storages

From Energy Conversion and Management:

• Sorption thermal energy storage: Hybrid coating/granules adsorber design and hybrid TCM/PCM operation

• Novel hybrid microencapsulated phase change materials incorporated wallboard for year-long year energy storage in buildings

From Thermochimica Acta:

• Experimental Investigation on Thermal Properties of Sodium Acetate Trihydrate based Phase Change Materials for Thermal Energy Storage

• The preparation of AgI/Au/foam-Cu as a framework of composite for water-based cool storage phase-change material with low supercooling

From Energy and Buildings:

• Nano-encapsulation of phase change materials: from design to thermal performance, simulations and toxicological assessment

• Investigation of phase change materials integrated with fin-tube baseboard convector for space heating

From Journal of Energy Storage:

• Nano-enhancement of phase change material in a shell and multi-PCM-tube heat exchanger

From Applied Energy:

• Numerical investigation of phase change material thermal storage for space cooling

From Journal of Materials Chemistry A:

• Vertically aligned carbon fibers as supporting scaffolds for phase change composites with anisotropic thermal-conductivity and good shape-stability

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,400 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,400 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Richard Koike, CEO at Tecentry LLC and Asia Pacific Enterprise Ltd., Ladera Ranch, Calif.; and Lukas Müller, research associate at Lucerne University of Applied Sciences and Arts, Lucerne, Switzerland.