The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

ACADEMIA

From left: Brandon Koyanagi, Will Wilson, Gerardo Rojo and Michelle Zdanowski

A look inside an undergraduate team’s solar thermal storage project

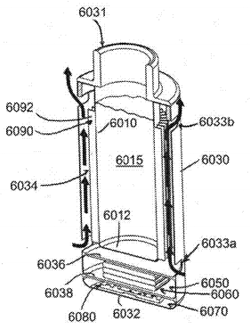

For their senior undergraduate project, four engineering students at Southern Illinois University Edwardsville developed a heat storage system designed to collect thermal energy from the sun and release it at night.

The Solar Owl combines water-based sensible heat storage in an insulated tank and latent heat storage through use of a hydrated salt phase change material. The PCM is contained in a continuous, multiple-coil vessel within the tank.

The team – Brandon Koyanagi, Will Wilson, Gerardo Rojo and Michelle Zdanowski – designed, analyzed, built and tested a scale prototype of the apparatus.

The team – Brandon Koyanagi, Will Wilson, Gerardo Rojo and Michelle Zdanowski – designed, analyzed, built and tested a scale prototype of the apparatus.

“At full size,” Wilson says, “the tank would be capable of heating an average American home through the evening and night, fourteen hours, using heat accumulated from solar thermal collectors during a typical St. Louis-area winter day. The Solar Owl reduces the size of the heat storage tank by 40 percent when compared to a sensible-only storage solution.”

The team earned an A on the project and will continue to develop the system in graduate studies. Aside from securing a patent on the design elements and a trademark on the name, the team has no immediate plans to commercialize the system.

Here’s a Q&A with Wilson, who was selected as Outstanding Senior in the university’s Mechanical Engineering Department this year.

Q: Why did the team choose sodium acetate trihydrate as the phase change material?

A: SAT fit our needs in four important ways. (1) SAT’s latent heat of fusion is high enough to keep tank size adequately small. (2) SAT, and the necessary additives, are readily availability at low to mid cost. (3) SAT exhibits low toxicity and is environmentally friendly. (4) The melting point of 58 C lends itself well to our application. This melting point is low enough to be completely melted by heat collected from a standard flat-plate solar thermal collector, while also providing a good temperature delta for most hydronic loop appliances.

Q: What is the source of the SAT you’re using?

A: We utilized SIUE chemistry lab space to synthesize a custom solution of lab-grade hydrated sodium acetate crystals with a small amount of additional water to slightly lower the temperature needed for complete melting. Carboxymethyl cellulose (CMC) was added to mitigate phase separation and potassium sulfate to minimize supercooling.

Q. Unmodified SAT’s latent heat of fusion is typically 264–289 joules per gram, with a melt point of 58 C. Does your SAT fit those specs?

A: Our SAT did fit within that range per gram of SAT in solution. Of course, the latent heat of fusion for the solution overall, including the extra water and additives, was somewhat lower.

Q: What triggers the release of the heat?

A: Heat is released as the tank temperature falls below the melting point (plus a correction for minimal supercooling, approximately 5 degrees Celsius).

Q: What are the key design elements of the container, and what material is it made of?

A: The PCM container is a set of interconnected concentric helical coils constructed from standard PEX tubing. A set of likewise interconnected helical heat transfer coils is interspersed between the PEX coils, allowing proximity of the heat source to melt the PCM during the day, with enough space between coils to allow free convective heat transfer to the surrounding water in the tank. This configuration has the following advantages:

• It holds a relatively large amount of PCM with large surface area for heat transfer to the water in the tank.

• The tubing diameter is small enough to allow for an adequate heat rejection rate from the PCM (given SAT’s low heat conductivity).

• The thermal conductivity of PEX is higher than many plastics, such that it does not present a bottleneck to the release of PCM heat.

For an extended version of this interview, see:

https://puretemp.com/pcmatters/solar-owl-tes-system

NEW PRODUCTS

Thanks to PCM insert, luxury chocolates melt in your mouth, not in the box

In hot climates, chocolates bought at retail shops can end up melting on the way home. Pluss Advanced Technologies of India has introduced a packaging insert to keep the sweets in solid form during transit.

Developed for ITC’s Fabelle line of premium chocolates, the insert features inorganic phase change material contained in a non-woven film. Vishnu Sasidharan, vice president of new product initiatives at Pluss, says the PCM was customized to keep the chocolate between 3º and 9º Celsius. The insert, designed for one-time use, measures about 170mm x 70mm. The goal is to maintain product quality and texture for one to two hours.

Developed for ITC’s Fabelle line of premium chocolates, the insert features inorganic phase change material contained in a non-woven film. Vishnu Sasidharan, vice president of new product initiatives at Pluss, says the PCM was customized to keep the chocolate between 3º and 9º Celsius. The insert, designed for one-time use, measures about 170mm x 70mm. The goal is to maintain product quality and texture for one to two hours.

“The product was launched about five months back,” Sasidharan says. “It was available only in one hotel chain within ITC group of hotels. The boutique has gained much traction only in the last few months with ITC expanding it to not only within their group but in all the 5 star/7 star hotels across India.”

Pluss is working with other chocolate/confectionary companies to offer similar solutions for premium temperature-sensitive products.

PATENTS

Cables made of phase change material

U.S. patent application 20170045301 (applicant E.I. Du Pont De Nemours and Co., Wilmington, Del.):

“Disclosed is a cable comprising a core and a PCM layer surrounding the core wherein the PCM layer consists of a PCM composition wherein the PCM composition comprises a PCM and an ethylene copolymer; and the core consists of a yarn, strand, or wire each made of a natural or synthetic polymeric material or a metal. The invention is useful for thermal management in a variety of applications in such as, for example, automotive, building, packaging, garments, and footwear.”

Heated or cooled dishware and drinkware and food containers

U.S. patent application 20170042373 (applicant Ember Technologies Inc., Westlake Village, Calif.):

“An actively heated or cooled food container can have a lid movable between an open and a closed position and an insulated body to which the lid can be attached. The insulated body can have a sidewall that defines a perimeter of the container body and a base, the sidewall and base defining one or more chambers that can be sealed by the lid. … The heating and cooling system comprises a cooling element comprising a phase change material disposed in a chamber that surrounds at least a portion of the inner sidewall so that the phase change material is in thermal communication with at least a portion of the inner sidewall of the portable body, the phase change material configured to transition from one phase to a second phase at a predetermined temperature. “

IN BRIEF

• The water utility in Hamburg, Germany, wants to build an underground thermal heat storage system that could supply about 25 percent of the city’s heating needs with waste heat from industrial and power plants. A huge saltwater aquifer below the city is seen as an ideal “thermal battery” in which to store heat for use in winter.

• The University of Nevada-Las Vegas entry in the 2017 Solar Decathlon will feature phase change material in the ceilings of the 900-square-foot home.

• Sonoco has announced a 10 percent price increase on all expanded polystyrene components used in its temperature-assurance packaging products. The company said the increase reflects the rising cost of polystyrene, the key raw material in EPS products.

• University of Colorado engineers have developed a metamaterial that can cool objects even under direct sunlight with zero energy and water consumption. The glass-polymer hybrid material measures just 50 micrometers thick and can be manufactured economically on rolls, making it potentially viable for large-scale residential and commercial applications.

• StoCalce Functio, a wall covering material developed by the Swiss research institute Empa together with the building specialist Sto, manages interior humidity by absorbing, storing and releasing moisture. Perhaps PCMs could be added to the material to manage temperatures as well. [German-language link]

• Alexium International, maker of Alexicool phase change material, is one of nine companies planning to attend Gabelli & Company‘s 8th annual Specialty Chemicals Conference in New York City on March 22.

• Axiom Exergy co-founders Anthony Diamond and Amrit Robbins, who made Forbes’ “30 Under 30” in the energy sector this year, shared advice for other young entrepreneurs on energy.gov. Said Robbins: “If you want to build a business, go out and get third party validation for your technology, team and product-market fit.”

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Renewable and Sustainable Energy Reviews:• Heat transfer enhancement of phase change materials for thermal energy storage applications: A critical review

From Energy and Buildings:

• Definition of a new set of parameters for the dynamic thermal characterization of PCM layers in the presence of one or more liquid-solid interfaces

• Establishment and experimental verification of TRNSYS model for PCM floor coupled with solar water heating system

From Applied Thermal Engineering:

• Thermal diffusivity measurement of erythritol and numerical analysis of heat storage performance on a fin-type heat exchanger

• Mixed mill-heating fabrication and thermal energy storage of diatomite/paraffin phase change composite incorporated gypsum-based materials

From International Journal of Heat and Mass Transfer:

• Melting enhancement in triplex-tube latent thermal energy storage system using nanoparticles-fins combination

From Applied Energy:

• Benefits of PCM underfloor heating with PCM wallboards for space heating in winter

From SAE World Congress Experience:

• Development and optimization of PCM-based technology for cooling applications for improvement of fuel efficiency in commercial vehicle

From University of Cincinnati (master’s thesis):

• Stratified Laboratory Thermal Energy Storage (LabTES) Tank Experiments: Sensible Only and Sensible Augmented with PCM-Filled Tubes

From Journal of Energy Storage:

• New proposed methodology for specific heat capacity determination of materials for thermal energy storage (TES) by DSC

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than a thousand of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members include Mareijn Gouw of Global-E-systems Europe B.V., Netherlands; Daniel Pounds, lead thermal engineer, ThermAvant Technologies, Columbia, Mo.; and Karl Marietta, vice president at FVB Energy Inc., Minneapolis, Minn.

You are invited to join the group and connect with PCM and TES experts from around the world. New members include Mareijn Gouw of Global-E-systems Europe B.V., Netherlands; Daniel Pounds, lead thermal engineer, ThermAvant Technologies, Columbia, Mo.; and Karl Marietta, vice president at FVB Energy Inc., Minneapolis, Minn.

• Suzanne Sinatra of New York asked the group for help with a project:

“I’m looking to insert micro PCM into a custom-shaped medical pouch. However, I’m looking for a vendor to combine the two to make my product. Any recommendations /suggestions are welcome. Thank you PCM members!

• Another member of the group, Dr. Harald Mehling, has started a ResearchGate project that might be of interest to newsletter readers. He writes:

“The goal of this project is to have a place where key publications for “Calorimetric measurements on PCM” can be collected, such that they can be easily found and also discussed efficiently. In the long run, this should lead to generally better data.

“As key publications are considered

“1) publications which lead to an improvement in a measurement result, e.g.

– by the design of a measurement system, including new ones

– by the calibration procedure, materials …

– by the measurement procedure,

– by the evaluation procedure, including corrections …

“2) publications leading to a reduction in the effort

“3) publications showing the accuracy achieved, including intercomparison tests (ring tests)

“Work on this has started long ago, for me in 2004, because of the demand of reliable data for quality control, as well as for application R&D. If anyone has a publication that he /she considers relevant, I would like to invite you to contact me. In the coming weeks I will try to draft a text that gives an overview of the publications that are collected and why.”

Thomas Haussmann (ISE) and Stephan Vidi and Christoph Rathgeber (both ZAE) are collaborating with Harald on the project. Here’s the URL:

YOUR TURN

Wanted: News tips about PCMs and thermal energy storage

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? We would love to hear from you. Please contact Ben Welter of Entropy Solutions at bwelter@puretemp.com.

Do you know someone who might be interested in this newsletter? Please send them a link to our signup page, puretemp.com/subscribe.