The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

MEDICAL

Penn researchers develop low-cost molecular diagnostic device

Point-of-care molecular diagnostic devices designed to detect HIV, tuberculosis and other pathogens have evolved rapidly in the past few years, addressing the need for simple tools that can be used outside specialized labs.

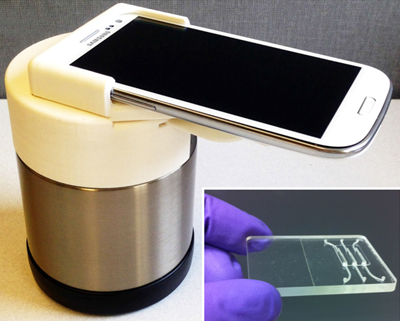

Now researchers at the University of Pennsylvania have designed, built and tested a portable, low-cost “smart cup” that uses phase change material to maintain a temperature of 60º to 65º Celsius during nucleic acid isothermal amplification.

Now researchers at the University of Pennsylvania have designed, built and tested a portable, low-cost “smart cup” that uses phase change material to maintain a temperature of 60º to 65º Celsius during nucleic acid isothermal amplification.

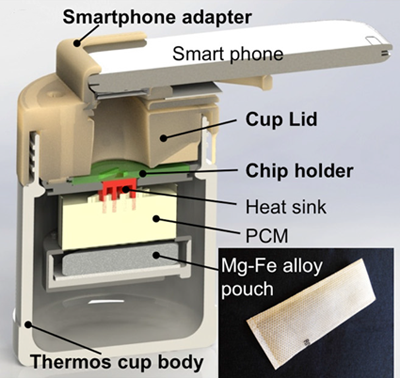

The device consists of an insulated Thermos cup, a 3D-printed lid, a microfluidic chip, a PCM reservoir, an Mg-Fe alloy pouch and a smartphone adapter. The current chip contains three multifunctional, isothermal amplification reactors for nucleic acid extraction and amplification. If needed, more reactors on single chip are possible for multiplex molecular diagnostics.

Water is added to the device to trigger an exothermic chemical reaction that supplies heat for the amplification process. Entropy Solutions’ PureTemp 68, a biobased phase change material with a melting temperature of 68 degrees Celsius, helps regulate the chip’s temperature.

Water is added to the device to trigger an exothermic chemical reaction that supplies heat for the amplification process. Entropy Solutions’ PureTemp 68, a biobased phase change material with a melting temperature of 68 degrees Celsius, helps regulate the chip’s temperature.

A mobile phone makes the device truly mobile: Its flashlight is used to excite fluorescent dye in the sample; its camera is used to record real-time fluorescence emission during the amplification process. The smartphone monitors the reactors and sends the data to a laptop computer for analysis. In future versions, a smartphone app will handle image processing, data analysis and communications, eliminating the need for a laptop.

For this prototype, the team used a commercially available cup with a diameter of 9 cm and height of 14 cm, including the lid and adapter. Custom-made versions will be considerably smaller.

The team estimates that the cost of a commercially produced smart cup (excluding the smartphone) will be less than $10.

The smart cup testing process is described in a paper scheduled for June publication in Sensors and Actuators: B:

“Our smart cup’s utility was demonstrated by amplifying and quantifying herpes simplex virus type 2 (HSV-2) with LAMP assay in our custom-made microfluidic diagnostic chip. We have consistently detected as few as 100 copies of HSV-2 viral DNA per sample. Our system does not require any lab facilities and is suitable for use at home, in the field, and in the clinic, as well as in resource-poor settings, where access to sophisticated laboratories is impractical, unaffordable, or nonexistent.”

Changchun Liu, research assistant professor at the University of Pennsylvania, talked about what’s next for the smart cup in an interview with Phase Change Matters.

“We are looking for opportunities to adapt our smart cup for various point-of-care tests,” Liu said. “The cup is also included in a few grant proposals for diagnostic tests. If funded, we will be able to test the smart cup in the field.

“We are amenable to industry collaborations and licensing. Interested companies are welcome to contact Penn Center for Innovation, which can be reached by contacting Dr. Sarah Johnson (johnsa@upenn.edu).”

PATENTS

Microencapsulation process for PCMs and other materials

U.S. patent application 20160088838 (applicant Imerys Minerals Ltd., Great Britain):

“A process for making microcapsules may include i) forming a solution of a cross-linker in a liquid; ii) forming a slurry of a surface-modified particulate inorganic material in an aqueous medium; and iii) dispersing the solution of step i) in the slurry of step ii) and causing or allowing the cross-linker to react with the surface-modified particulate inorganic material so as to form a cross-linked microcapsule wall. … A wide range of active materials (active ingredients) may be encapsulated including inks, flavours, cosmetics, perfumes, sunscreens, fragrances, adhesives, sealants, phase change materials, biocides, oilfield chemicals (including corrosion and scale inhibitors), flame retardants, food additives (including vitamins, ingredients, probiotics and antioxidants) …”

BUILDING AND CONSTRUCTION

PCMs helped this tiny house achieve Passivhaus status

Designing a house that meets Passivhaus standards is made more difficult when the house is small. A small house has more surface area per cubic foot of living space than a large one. Thick concrete walls aren’t the most efficient way to achieve thermal mass in a house of less than 130 square feet.

Thomas Primault, the designer of Mizu, a Japanese-style timber structure in Bretagne, France, chose another option: 6 mm of Enerciel wall coating impregnated with phase change material. The biobased PCM has a melt point of 23° Celsius, absorbing heat when the temperature inside the tiny office structure climbs above 23, and releasing heat when the temperature falls below 23. The building envelope also includes vacuum insulated panels in the floor and mineral fiber insulation in the ceiling and walls.

TreeHugger’s Lloyd Alter describes the result, a tiny house that meets Passivhaus standards, as “a stunning little gem.” Blogger Elrond Burrell writes that monitoring data and experience indicate that the building is performing very well, but “it isn’t obvious how much the PCM is playing a part in the performance.”

IN BRIEF

• Manufacturers who want to underscore the safety of a chemical they make can submit it for inclusion in the Environmental Protection Agency‘s Safer Chemical Ingredients List. Chemicals that qualify are eligible for use in products that carry the Safer Choice label.

• New research from Future Market Insights: “Energy Harvesting Market: Global Industry Analysis and Opportunity Assessment 2014-2020.”

• Researchers at the University of Toronto have developed a gel that can break apart molecules of water at about three times the rate and far more cheaply than any other known substance. “If its effectiveness proves long lasting,” the Globe and Mail reports, “it could pave the way for a new and commercially attractive method for storing renewable energy.”

• MBS Naturstromspeicher of Germany has introduced a line of thermal natural heat accumulators in the form of pools, fountains and natural-looking ponds. Storage capacities range from 5 kW to more than 300 kW. A fan is used to speed thermal recharging, and the stored energy is used to heat or cool nearby buildings with the help of a heat pump.

• Business opportunity: Lawrence Livermore National Laboratory seeks to establish a collaboration to develop and commercialize an invention can harvest mechanical and thermal energy by combining nanowires and phase change materials.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Only a few PCM- and TES-related papers were posted this week:

From Applied Thermal Engineering:• Phase change behaviour of latent heat storage media based on calcium chloride hexahydrate composites containing strontium chloride hexahydrate and oxidation expandable graphite

• Performance study of latent heat accumulators: numerical and experimental study

From Renewable and Sustainable Energy Reviews:

• Materials and system requirements of high temperature thermal energy storage systems: A review. Part 2: Thermal conductivity enhancement techniques

From Solar Energy:

• Evaluation of copper nanoparticles – Paraffin wax compositions for solar thermal energy storage

• Latent heat storage by silica-coated polymer beads containing organic phase change materials

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

The Phase Change Matters group on LinkedIn is celebrating its one-year anniversary. The group is devoted to the discussion of phase change material and thermal energy storage. It has grown to nearly 700 members.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Mile Vujicic, business and technology development director at Sterling Thermal Technology Ltd., United Kingdom; Vivien Godefroy, thermal engineering manager at MCI Technologies, France; Silvan von Arx, mechanical engineer at Lucerne University, Switzerland; and Shivangi Sharma, Ph.D. researcher at the Environment and Sustainability Institute, University of Exeter, United Kingdom.

Eduardo Martín Krunfli, who is working on a master of science degree in sustainable engineering at Villanova University, asked the group for help with a microencapsulation question:

“I am performing a rough LCA on the microencapsulated PCM-embedded Trombe wall and I would like to know if some of you have an approximation of the energy needed for the microencapsulation process (the materials have already been considered, this is just heat, mix, etc to obtain the microcapsules). It doesn’t need to be extremely precise, just a rough kWh/kg of production will be perfect.”

OUR TURN

Phase Change Matters is taking a break

Ben Welter, newsletter editor, is on vacation next week but will be checking email occasionally. If you have a news tip, please send details to bwelter@puretemp.com. Look for the next newsletter on April 15. Hasta luego!