The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

NEW PRODUCTS

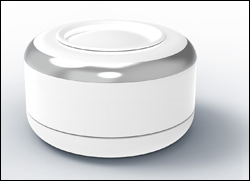

Bio-PCM battery shows promise in home heating system

A home heating system equipped with a PCM battery put up encouraging numbers in a small trial in northern Italy earlier this year. The monthlong test “shows that is possible [for such a system] to supply the whole heating demand of a house reducing close to zero the costs,” says Domenico Feo, who developed the system. The full report, prepared by ThermaLink, a trademark of Sunservice Srl of Treviso, Italy, is available here.

The system is composed of a 6 kW solar array, an air/water heat pump and a thermal battery filled with BioPCM Q42, a biobased phase change material supplied by Phase Change Energy Solutions of Asheboro, N.C. A control unit, PCDCube, monitors temperatures and manages energy flow to optimize system performance. In an interview with Phase Change Matters, Feo answered questions about the heat battery, recently rebranded as ThermaCube.

The system is composed of a 6 kW solar array, an air/water heat pump and a thermal battery filled with BioPCM Q42, a biobased phase change material supplied by Phase Change Energy Solutions of Asheboro, N.C. A control unit, PCDCube, monitors temperatures and manages energy flow to optimize system performance. In an interview with Phase Change Matters, Feo answered questions about the heat battery, recently rebranded as ThermaCube.

Q: Thermal conductivity has proven to be a challenge in thermal energy storage across most types of PCM. Was conductivity an issue with the required charge/discharge cycles?

A: “As already known, the thermal conductivity of the PCM, especially of the organic one that we use, is low. This is, at the same time, a disadvantage and an advantage. The disadvantage has been minimized in using a heat exchanger made with a flat aluminum panel with the various layers just over 1 inch of distance; in this way we are able to make the entire volume of material work in a very efficient way. Vice versa this is an advantage for the very low heat losses during the non-work phases; in conditions of installations inside the buildings, the temperatures can be maintained for several days.”

Q: If faster heat transfer is required, do you envision a redesign of the heat exchanger or a modification of the PCM to meet the demand of the energy transfer?

A: “As manufacturer, we can customize the heat exchanger dimensions and shape in order to achieve our goals, but as always in the industrial scalability, the quantities are mandatory for a good price. We designed a single heat exchanger dimension and multiply it in order to be able to produce the different storage capacities and realize a complete modular range. The transfer of energy can be however accelerated by increasing the flow rate of the fluid and the delta T between the fluid and the melting point, of course there is always a limit to this possibility. There are still studies around this point that need to be better understood.”

Q: Would implementing several PCMs of different melting temperatures aid in the overall performance of the TES?

A: “Let’s say that we expect a slight drop in performance at lower temperatures, but we don’t have many other tests to give you a more general opinion.”

Q: How is the PCM temperature measured throughout the entire storage to provide input to the PCDCube? Since the melting/solidification of PCM is not a homogenous process, are multiple measurements necessary to get a realistic status of the PCM?

A: “In the documents that we have published, we do not specify that we have installed two temperature probes, one in the center and another one near the walls and it is evident that, when the final phase of the discharge of the PCM approaches, the perimeter probe shows a decrease of more sudden temperature than the central one. We, however, assume that the fact of having installed our thermal battery outside the building in a very cold climate, has exaggerated the heat loss despite the low heat transmission.”

Q: Have you considered other PCM suppliers/products, since many are located in Europe and the RAL quality organization is based there?

A: “This is a possibility, at least for the distribution of our products in Europe and Asia. Currently we try to separate the supply of the case with exchangers (that we manufacture) from the PCM with direct purchase of the client from the supplier, especially in the larger units.”

Q: What is the customer value proposition for this product? What is the expected return on investment/payback period?

A: “This is a $1 million question; the proposal is certainly into the growing wave of the storage market, even the electrical ones for PV systems. (A Tesla Powerwall is cool but not economically advantageous if you don’t pay attention at the payback that is higher than the life of the battery). The best value proposition is to separate production from the consumption of the energy and take advantage of renewable energies which, unfortunately, are linked to the day / night cycle and the outdoor temperature conditions. We see perfect the combination HP + Thermal Battery because we can concentrate the HP working hours during the best outdoor conditions that, for many reasons, are affecting and reducing the performances. Furthermore, we also see a large market in the use of these thermal batteries in all these existing systems which are undersized or which, due to specific situations of changing use of the building, are no longer able to provide the necessary heating or cooling to the whole plant. About the ROI, this really varies a lot country by country because the cost of the electricity has different rates and peak hours schedules. The industrial needs are sometimes much more interesting and attractive than the residential ones.”

Q: What are your plans for a commercial rollout?

A: “We are completing the Italian sales force and are looking for international distributors. Our goal is to propose the range of products at an international level with distribution agreements for the case only with exchangers; it will be our responsibility to direct the partner to some reliable and high-quality PCM manufacturers. Obviously, those who will quickly give us the opportunity to build pilot plants, demonstrating the technology, will have an advantage in introducing them into the market and in the exclusivity of the contractual relationship.”

PATENTS

Beaded polymeric fibers with advanced thermoregulating properties

U.S. patent application 20200255980 (applicant Rensselaer Polytechnic Institute, Troy, N.Y.):

“A network of microfibers are fabricated with a core-shell construction from sustainable materials, where the core includes a phase-change material, such as coconut oil, and the shell includes a biomass, such as cellulose. The microfibers are made via a wet-wet electrospinning process utilizing a coaxial spinneret with an inner conduit and an outer conduit. The biomass and the phase-change material are coaxially extruded into a coagulation bath including a mixture of ethanol and water. The collected microfibers exhibit a beaded structure of PCM aggregates and biomass connecting regions between the aggregates and are effective to aid in the thermoregulation of the immediate environment surrounding the network. The microfibers are suitable for use in a variety of sustainable products such as wearable thermoregulating textiles, wall/ceiling panels, insulation, packaging material, and more.”

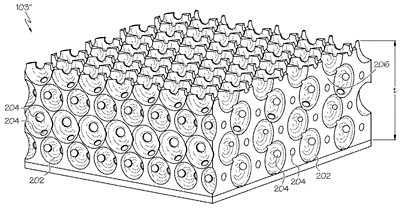

Encapsulated phase change porous layer

U.S. patent application 20200258811 (applicant Toyota Motor Engineering & Manufacturing North America Inc., Plano, Texas):

U.S. patent application 20200258811 (applicant Toyota Motor Engineering & Manufacturing North America Inc., Plano, Texas):

“A cooling device including an encapsulated phase change porous layer that exhibits an increased heat capacity is disclosed. The encapsulated phase change porous layer may include a sintered porous layer, a phase change material formed over the sintered porous layer, and an encapsulation material formed over the phase change material. The encapsulation material may encapsulate the phase change material between the encapsulation material and the sintered porous layer and retain the phase change material between the encapsulation material and the sintered porous layer when a fluid is flowed through or in contact with the encapsulated phase change porous layer.”

Thermal management of energy storage devices via heat pipe

U.S. patent application 20200266504 (applicant ThermAvant Technologies LLC, Columbia, Mo.):

“A thermal management system for the at least one energy cell. The thermal management system includes a cold plate cell holder comprising at least one energy cell reservoir structured to retain the energy cell(s) and surround at least a first portion of a surface of the energy cell(s), and to thermally cool the energy cell(s). The system additionally includes a bus bar header to which one or more bus bar can be physically and thermally connected, and at least one oscillating heat pipe (OHP) cover disposable around a second portion of the surface of the energy cell(s). The OHP cover(s) is/are thermally and mechanically connectable to the cold plate cell holder when disposed around the energy cell(s). The OHP cover(s) is/are structured and operable to thermally cool the energy cell(s) via heat absorption from the second portion of the surface of the energy cell(s) when disposed around the energy cell(s).”

System and method for bodily fluid capture and preservation

U.S. patent application 20200261315 (applicant Dadi Inc., Brooklyn, N.Y.):

“System and associated method for capturing, preserving, and transporting a bodily fluid, including a collection jar having a base body, a lid body, and a cartridge having a plunger therein and disposed in the lid body, the cartridge housing a preservative when the plunger is in a first plunger position and permitting a release of the preservative into an internal cavity of the collection jar when the plunger is in a second plunger position, and a transportation packaging having an outer container, at least one insulation foam support, at least one phase change material bottle, and at least one collection jar holding tray, where the phase change material bottle has an indented portion corresponding to an indented portion of the collection jar holding tray, and where the collection jar is configured for placement in the at least one collection jar holding tray during transportation.”

“System and associated method for capturing, preserving, and transporting a bodily fluid, including a collection jar having a base body, a lid body, and a cartridge having a plunger therein and disposed in the lid body, the cartridge housing a preservative when the plunger is in a first plunger position and permitting a release of the preservative into an internal cavity of the collection jar when the plunger is in a second plunger position, and a transportation packaging having an outer container, at least one insulation foam support, at least one phase change material bottle, and at least one collection jar holding tray, where the phase change material bottle has an indented portion corresponding to an indented portion of the collection jar holding tray, and where the collection jar is configured for placement in the at least one collection jar holding tray during transportation.”

Mattress assemblies including panel with PCMs

U.S. patent application 20200260882 (applicant Dreamwell Ltd., Atlanta, Ga.):

“A mattress assembly comprising: at least one layer proximate to a sleeping surface of the mattress assembly spanning at least a portion of the length and/or width of the sleeping surface comprising: a two-ply preformed capsulate sheet comprising a plurality of cells; and a phase change material within at least a portion of the plurality of cells.”

PCM compositions and methods for their use to lower friction and wear

U.S. patent application 20200248090 (applicant: Texas A&M University System, College Station, Texas):

“Phase change material compositions and methods for using the compositions to prepare substrate coatings or bulk blended polymers that advantageously lower friction between interacting substrate surfaces and lower substrate surface wear.”

Gel composition comprising a phase change material

U.S. patent application 20200231857 (applicant Croda International Plc, East Yorkshire, Great Britain; inventors Atug Altay and Marco Auerbach):

“The present invention provides a composition comprising a) a phase change material; b) 1 to 10 wt % of a silica gelling additive; and c) a styrene co-polymer gelling additive; wherein the composition is in the form of a gel and wherein the weight ratio of b) silica gelling additive to c) styrene co-polymer gelling additive in the composition is in the range from 0.6 to 5:1. The invention also provides a method of making the composition and an article and a product comprising the composition. Finally, the invention provides the use of a combination of a silica gelling additive and a styrene co-polymer gelling additive to make a gel composition comprising a phase change material with one or more improved properties.”

IN BRIEF

• Sonoco ThermoSafe and ACL Airshop have announced a global agreement for the handling and repair of ThermoSafe’s Pegasus ULD bulk temperature-controlled containers. ACL Airshop, of Greenville, S.C., provides cargo support equipment and logistics solutions for airlines and air cargo carriers. Sonoco says the unit load device is made of composite materials that are lighter and more damage-resistant than traditional metal containers. It uses a gelled phase change material to maintain pharmaceutical-safe temperatures for five days or more, depending on the PCM used.

• Sonoco ThermoSafe and ACL Airshop have announced a global agreement for the handling and repair of ThermoSafe’s Pegasus ULD bulk temperature-controlled containers. ACL Airshop, of Greenville, S.C., provides cargo support equipment and logistics solutions for airlines and air cargo carriers. Sonoco says the unit load device is made of composite materials that are lighter and more damage-resistant than traditional metal containers. It uses a gelled phase change material to maintain pharmaceutical-safe temperatures for five days or more, depending on the PCM used.

• Has long-term thermal energy storage come of age? That’s the premise of a recent advertorial sponsored by Viking Cold Solutions on Greentech Media‘s website. The Houston company says its PCM-based system, designed for use in cold storage facilities, stores enough energy to cycle off refrigeration for up to 13 hours per day and reduce energy consumption by more than 25 percent. Not much new in the article, but the reader comment section might be of interest to people who are familiar with the technology.

• A cycling club in Great Britain teamed up with Peli BioThermal this summer to deliver temperature-sensitive prescriptions to housebound people. The company supplied Banbury Star Cyclists with Crēdo ProMed temperature-controlled medical transport bags. The PCM-equipped bags are designed to transport pharmaceutical samples and medical supply payloads within two ranges, 2-8°C and 15-25°C.

• Phase Change Energy Solutions of Asheboro, N.C., has a new chief executive officer. Govi Rao, co-founder and managing partner at CARBON Group Global, joined the company in April. His predecessor, Dennis McGill, had held the position since December 2018.

• Sunamp Ltd. of Scotland has raised 4.5 million pounds in a Series A financing round led by Chilean venture capital firm Aurus Capital. Sunamp says it will use the funds to support commercial scaling in the United Kingdom and expansion in Central Europe, Asia and North America.

• The 15th Conference on Advanced Building Skins will be held as scheduled Oct. 26-27 in Bern, Switzerland. “In the unlikely event that the conference will not take place, or the participant may not be able to travel,” organizers say, “paid registration will be credited to our conference next year.” The 12 sessions, with over 70 presentations, will also be available online.

• A four-man canoe team put Glacier Tek‘s PureTemp-powered cooling vests to the test last month in a 340-mile paddle race from Kansas City to St. Charles, Mo. Team Mississippi, led by Scott Miller, 44, of Minneapolis, finished 11th overall in the Missouri 340, completing the course in 44 hours, 38 minutes. The race drew more than 350 entries. Team Mississippi used the vests to cool down at checkpoint stops. Miller, second from left in the photo, plans to use the vests to battle the heat in the Great Alabama 650, which bills itself as the world’s longest annual paddle race. That event begins Sept. 26 on the Coosa River in northern Alabama.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Journal of Molecular Liquids:• The research progress on phase change hysteresis affecting the thermal characteristics of PCMs: A review

From Journal of Building Engineering:

• Thermal behavior of a phase change material in a building roof with and without reflective coating in a warm humid zone

From Renewable Energy:

• A comprehensive study on thermal storage characteristics of nano-CeO2 embedded phase change material and its influence on the performance of evacuated tube solar water heater

From Sustainable Cities and Society:

• Numerical analysis of phase change materials for optimizing the energy balance of a nearly zero energy building

From Journal of Energy Storage:

• Multi-objective optimization of cooling and heating loads in residential buildings integrated with phase change materials using the artificial neural network and genetic algorithm

• Assessing corrosive behaviour of commercial phase change materials in the 21–25 ºC temperature range

• Exergy and economic analyses of nanoparticle-enriched phase change material in an air heat exchanger for cooling of residential buildings

• Experimental and numerical investigation on enhancing heat transfer performance of a phase change thermal storage tank

• The effect of ultraviolet coating on containment and fire hazards of phase change materials impregnated wood structure

From Energy Conversion and Management:

• Application of granular materials for void space reduction within packed bed thermal energy storage system filled with macro-encapsulated phase change materials

From Chemical Engineering Journal:

• Simultaneous solar-thermal energy harvesting and storage via shape stabilized salt hydrate phase change material

From Solar Energy:

• Characterization and cooling effect of a novel cement-based composite phase change material

• Effect of polymer-derived silicon carbonitride on thermal performances of polyethylene glycol based composite phase change materials

From Case Studies in Thermal Engineering:

• Effect of porosity and pore density of copper foam on thermal performance of the paraffin-copper foam composite Phase-Change Material

From Renewable and Sustainable Energy Reviews:

• A critical assessment on synergistic improvement in PCM based thermal batteries

From Journal of Energy Resources Technology:

• Experimental Analysis of Salt Hydrate Latent Heat Thermal Energy Storage System With Porous Aluminum Fabric and Salt Hydrate as Phase Change Material With Enhanced Stability and Supercooling

From Energy Sources:

• Experimental study on thermal management and performance improvement of solar PV panel cooling using form stable phase change material

• Experimental investigation of thermal performance of indirect mode solar dryer with phase change material for banana slices

From Aalto University:

• Experimental design and investigation on a thermal energy storage system using phase change materials [thesis]

From Journal of Applied Physics:

• Development of eco-sustainable plasters with thermal energy storage capability

From Chemical Engineering Transactions:

• Thermal Performance of Phase Change Material Wallboard with Typical Structure: Artificial Controlled Condition Experimental Investigation

From Materials Research Express:

• Fabrication of thermal energy storage wood based on graphene aerogel encapsulated polyethylene glycol as phase change material

• Preparation and characterization of acrylic resin encapsulated n-dodecanol microcapsule phase change material

From ACS Sustainable Chemical Engineering:

• Synthesis and Characterization of Fatty Acid Amides from Commercial Vegetable Oils and Primary Alkyl Amines for Phase Change Material Applications

From Carbohydrate Polymers:

• Fibrous form-stable phase change materials with high thermal conductivity fabricated by interfacial polyelectrolyte complex spinning

• Effect of various phase change materials (paraffin wax/hydrogenated vegetable oil) packed in a fabricated shell and tube type heat exchanger

From Solar Energy Materials and Solar Cells:

• Composite phase change materials with heat transfer self-enhancement for thermal energy storage

• Novel network structural PEG/PAA/SiO2 composite phase change materials with strong shape stability for storing thermal energy

From International Journal of Refrigeration:

• Improving the performance of household refrigerating appliances through the integration of phase change materials in the context of the new global refrigerator standard IEC 62552:2015

From Advances in Colloid and Interface Science:

• Nanoencapsulation of phase change materials (PCMs) and their applications in various fields for energy storage and management

From Building and Environment:

• Space heating performance of novel ventilated mortar blocks integrated with phase change material for floor heating

From Energy:

• A promising form-stable phase change material composed of C/SiO2 aerogel and palmitic acid with large latent heat as short-term thermal insulation

From Journal of Cleaner Production:

• Enhanced thermal storage capacity of paraffin/diatomite composite using oleophobic modification

From International Conference on Renewable Energies for Developing Countries:

• Storage efficiency of paraffin-LDPE-MWCNT phase change material for industrial building applications

• Effects of a cooling vest with sham condition on walking capacity in heat-sensitive people with multiple sclerosis

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,550 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,550 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This summer we welcomed more than 30 new members, including Laura Quant Colón, researcher at Universidad del País Vasco, Spain; Purna Pushkala Somasundaram, graduate student in chemical engineering at Politecnico di Milano, Italy; Steven Tay, associate professor at Singapore Institute of Technology, Singapore; Kévin Bozec, business development and technical marketing at Croda, Nantes, France; Richard Stevenson, research officer at M&I Materials Ltd., Manchester, United Kingdom; Mike Yan, senior product manager at Qingdao Thermal New Materials Co. Ltd., Qingdao, China; and Diptapal Moitra, business development manager, India and Middle East, at Vertellus, Pune, India.