The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

AUTOMOTIVE

PCM-based system heats electric vehicle without draining battery

Cold climates pose a challenge for electric vehicles: With no engine to serve as a heat source, EVs rely on batteries alone to warm the cabin and defrost the windshield. Running the heater quickly drains batteries and can reduce driving range by as much as 60 percent. That can make a routine commute a frosty and mitten-biting affair in places like International Falls, Minn., where temperatures dip well below freezing on a typical January morning.

Using phase change material developed by Entropy Solutions, engineers at MAHLE, one of the world’s largest automotive suppliers, found a solution. They have developed a prototype of a thermal energy storage system that is expected to extend the range of EVs by 20 to 40 percent in cold conditions.

PCMs are substances that absorb and release thermal energy during the process of melting and freezing. The MAHLE system uses a PCM’s stored latent heat to provide cabin heating. The PCM is melted while the vehicle battery is charged from the electrical grid. The stored heat is transferred to the cabin as the PCM solidifies during driving. The system provides enough thermal energy to heat the cabin for about 46 minutes, the typical daily commute time for American drivers.

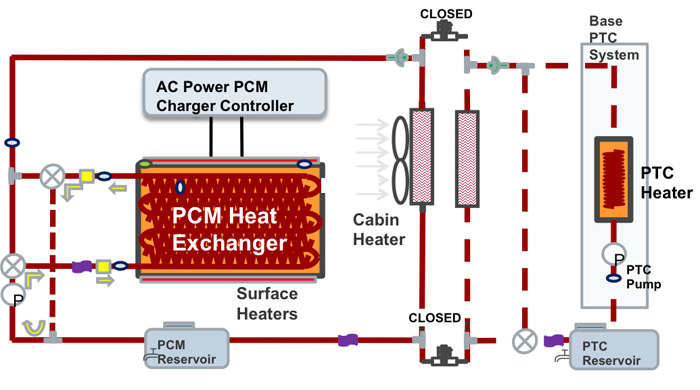

At the heart of the electrical PCM-assisted thermal heating system (ePATHS) is a high-efficiency PCM heat exchanger. Because heat transfer is a critical factor in system performance, MAHLE engineers chose a two-pass flow exchanger with a number of rectangular tube rows sandwiched between stacks of finned PCM chambers. An electric pump runs a water-glycol mixture through the PCM heat exchanger, absorbing heat from the PCM and flowing to a heater under the dashboard.

The design is similar to that of a standard automobile radiator, but with a fully enclosed PCM containment shell. The heat transfer fluid flows through channels in direct contact with the PCM chambers. The exchanger is enclosed in a high-performance vacuum insulation panel to minimize heat loss.

Entropy Solutions of Plymouth, Minn., developed two novel bio-based phase change materials to match the needs of the new system. The PCM chosen, DPT83, has a melting point of 83° C (181° F) and a latent heat value of 348 joules per gram. DPT83’s relatively high latent heat capacity, well above the 200 J/g of older PCMs, helps minimize system size and weight. The 33-kilogram, 31-liter prototype includes 19 kg of phase change material.

Entropy researchers were able to synthesize the DPT83 beginning with natural vegetable-based feedstocks. They found that the PCM is compatible with aluminum and are conducting additional compatibility studies.

“Most organic based PCMs have latent heats of around 150 to 210 joules per gram,” said Dr. William R. Sutterlin, Entropy’s chief science officer. “Water has a latent heat of around 330 joules per gram. I had always wondered if we could make an organic PCM that could beat water. We did it.”

The $3.5 million, three-year collaborative research project, with 50 percent funding from the U.S. Department of Energy, is detailed in two technical papers published in April by SAE International, “Design and Testing of a Thermal Storage System for Electric Vehicle Cabin Heating” and “Thermal Storage System for Electric Vehicle Cabin Heating – Component and System Analysis.”

“The PCM-based thermal storage system provides a commercially viable technology to mitigate range anxiety of electric vehicles in the marketplace. We are working closely with vehicle OEMs to commercialize the technology in the near future,” said Tim Craig, MAHLE’s U.S. Advanced HVAC System manager.

NEW PRODUCTS

RGEES launches Akuratemp specimen transporter in four temperature ranges

RGEES introduced a new line of temperature-controlled specimen transporters this week at CleanMed 2016 in Dallas.

The Akuratemp line is available in frozen (below -20° C), chilled (2-8° C), room temperature (15°C to 25°C) and incubating (37° C) temperature ranges. The ranges cover applications in clinical trials, diagnostic specimens, and direct-to-patient and direct-to-lab deliveries. The transporter consists of an insulated carton, two color-coded packs containing phase change material (shown here), an optional real-time data logger and an outer sleeve.

The Akuratemp line is available in frozen (below -20° C), chilled (2-8° C), room temperature (15°C to 25°C) and incubating (37° C) temperature ranges. The ranges cover applications in clinical trials, diagnostic specimens, and direct-to-patient and direct-to-lab deliveries. The transporter consists of an insulated carton, two color-coded packs containing phase change material (shown here), an optional real-time data logger and an outer sleeve.

The company, based in Arden, N.C., says the “environmentally friendly” shippers will maintain temperatures for up to 72 hours, use salt-hydrate and bio-based phase change material and have reusable components. The shippers measure 305 x 203 x 203 millimeters.

PATENTS

Tube with phase change material for vehicle air conditioning system

U.S. patent application 20160137019 (applicant Valeo Systemes Thermiques, France):

“A tube (13) has a container of phase change material (M) for a heat exchange bundle of a heat exchanger of an air conditioning system of a passenger compartment of a vehicle. The tube includes a first plate (15) configured to form a first outer surface (17) of the tube, a second plate (19) configured to be sealingly assembled with the first plate and to form a second outer surface (21) opposite the first outer surface, and an intermediate plate (23) configured to be sealingly assembled with the first and second plates, between the latter, and to define on either sides thereof at least one channel (9) for the flow of a coolant (F) into the bundle and at least one recess (25) for the phase change material. The invention also relates to a heat exchange bundle and to a method for assembling a heat exchanger including the tube.”

“A tube (13) has a container of phase change material (M) for a heat exchange bundle of a heat exchanger of an air conditioning system of a passenger compartment of a vehicle. The tube includes a first plate (15) configured to form a first outer surface (17) of the tube, a second plate (19) configured to be sealingly assembled with the first plate and to form a second outer surface (21) opposite the first outer surface, and an intermediate plate (23) configured to be sealingly assembled with the first and second plates, between the latter, and to define on either sides thereof at least one channel (9) for the flow of a coolant (F) into the bundle and at least one recess (25) for the phase change material. The invention also relates to a heat exchange bundle and to a method for assembling a heat exchanger including the tube.”

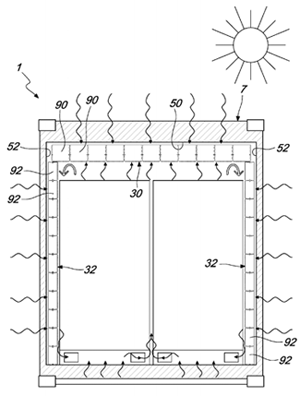

Device for conserving, transporting fresh or frozen products

U.S. patent application 20160109187 (applicant Thermo King Corp., Bloomington, Minn.):

“An apparatus for a thermally insulated container is disclosed. The apparatus includes one or more heat accumulators. Each of the thermal accumulators includes a plurality of longitudinal heat accumulation modules. Each of the longitudinal modules includes a casing forming a cavity therein.

“An apparatus for a thermally insulated container is disclosed. The apparatus includes one or more heat accumulators. Each of the thermal accumulators includes a plurality of longitudinal heat accumulation modules. Each of the longitudinal modules includes a casing forming a cavity therein.

“The cavity is configured to receive a phase change material. A first wall of the casing includes a substantially flat surface and a second wall includes a heat transfer enhanced surface portion. The longitudinal modules include a heat exchanger having at least a portion disposed within the cavity that is configured to supply a heat transfer fluid. The plurality of longitudinal heat accumulation modules are securely connected to each other and are in thermal communication with each other.”

ACADEMIC RESEARCH

Binary wax combinations show variety of melting/crystallization behaviors

Two Utah State University researchers have documented how the melting and crystallization of four waxes (beeswax, sunflower wax, rice bran wax and paraffin wax) changed as they were combined into various binary mixtures.

In an article published in the April issue of Journal of the American Oil Chemists’ Society, graduate research assistant Sarbojeet Jana and Associate Professor Silvana Martini reported that addition of as little as 20 percent of one wax to another could dramatically influence phase behavior.

“The pseudo-phase diagram and microstructure of binary waxes at different concentrations aids in understanding crystalline network formation and in developing new products for all types of industry,” the pair concluded. “… Waxes with similar chemical composition can co-crystallize, forming ideal solid solutions, while waxes with significantly different chemical composition can show either eutectic or monotectic behavior.”

“Phase Behavior of Binary Blends of Four Different Waxes,” selected as the journal’s article of the month, is available for free download through July 18.

IN BRIEF

• Pluss Advanced Technologies’ MiraCradle neonatal cooling device is featured in the spring issue of DEM+ND, the American Society of Mechanical Engineers‘ quarterly review of global development.

• Sunamp Ltd. is one of five companies representing Edinburgh, Scotland, in business presentations in Shenzhen, China, this week. Sunamp is hoping to expand the market for its “heat batteries,” which use phase change material to store excess energy generated by solar PV systems. The stored energy is released on demand to provide heat and hot water.

• Drs. William Sutterlin and Heather Watson of Entropy Solutions attended the American Oil Chemists’ Society conference in Salt Lake City earlier this month. Session topics included novel waxes with unique thermal characteristics, emulsion formation, crystallization growth of lipid materials and new analytical techniques.

• The global caprylic acid market is expected to reach $4.9 million by 2022, according to Stratistics Market Research Consulting.

• A rare sighting: Ice-based thermal storage pioneers CALMAC and Ice Energy are featured in the same article. Canada’s Plumbing+HVAC magazine takes a look at a CALMAC project at the University of Waterloo and an Ice Energy project in Boothbay, Maine.

• Puma‘s new Blaze golf shoe for women features Outlast phase change technology to promote thermal comfort.

• Puma‘s new Blaze golf shoe for women features Outlast phase change technology to promote thermal comfort.

• The Chemical Footprint Project, a global initiative designed to measure corporate progress in adopting safer chemicals, will issue its first report this month. Richard Liroff, executive director of the Investor Environmental Health Network, examines Wal-Mart‘s impact on the project.

• Portugal ran for a record four days straight on renewable energy alone last week. Solar, wind and hydro power typically account for about half of the country’s electricity needs. Renewables provided only about 23 percent as recently as 2013, the Guardian reports.

• The PCM 2016 conference in Karlsruhe, Germany, drew more than 60 participants this week. In opening sessions, Drs. Thomas Johansson of the International Institute for Industrial Environmental Economics and Hans-Martin Henning of Fraunhofer ISE touched on the importance of thermal storage for heating and cooling efficiency and a sustainable energy future.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Industrial Applications for Intelligent Polymers and Coatings:• Smart Polymeric-Based Microencapsulation: A Promising Synergic Combination

From Automobile Engineering:

• Mild hybrid technique using the automotive air-conditioning system

From Materials:

• Determination of Specific Heat Capacity on Composite Shape-Stabilized Phase Change Materials and Asphalt Mixtures by Heat Exchange System

From Journal of Chemical Thermodynamics:

• Solid–liquid phase equilibria of (n-octadecane with myristic, and palmitic acid) binary mixtures used as phase change materials (PCMs)

From Applied Thermal Engineering:

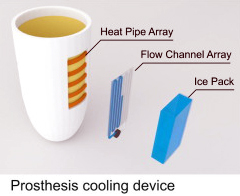

• An Automatic and Portable Prosthetic Cooling Device with High Cooling Capacity Based on Phase Change

• An Automatic and Portable Prosthetic Cooling Device with High Cooling Capacity Based on Phase ChangeFrom Renewable and Sustainable Energy Reviews:

• Thermal energy storage system integration forms for a sustainable future

From Journal of Theoretical and Applied Mechanics:

• A PCM-Water Heat Exchanger With Polymeric Hollow Bres For Latent Heat Thermal Energy Storage: A Parametric Study Of Discharging Stage

From Energy and Buildings:

• Impact of the enthalpy function on the simulation of a building with phase change material wall

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

Nearly 750 of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts and industry observers from around the world. New members this week include John Costa, product design engineer at Taco Inc., Fall River, Mass.; Sarbojeet Jana, graduate research assistant at Utah State University; Mike Wilson, staff engineer at LoadPath, Albuquerque, N.M.; and Anjam Butt, chief financial officer at SBS Mining Ltd., London.