The Phase Change Matters e-mail newsletter is monthly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is monthly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog www.puretemp.com/pcmatters.

INDUSTRY NEWS

Chinese manufacturer joins RAL Quality Association PCM

Hangzhou Ruhr New Material Technology Co. of Hangzhou City, China, has joined the RAL Quality Association PCM.

The company, known as RuhrTech, develops phase change materials and PCM products for use in food and pharmaceuticals packaging; cooling and temperature control in the fields of electronic devices and power batteries; and energy-saving applications for central air conditioning, cold storage and buildings. Its cold-chain packaging customers include Johnson & Johnson, Allergan and Lilly.

The company, known as RuhrTech, develops phase change materials and PCM products for use in food and pharmaceuticals packaging; cooling and temperature control in the fields of electronic devices and power batteries; and energy-saving applications for central air conditioning, cold storage and buildings. Its cold-chain packaging customers include Johnson & Johnson, Allergan and Lilly.

Dr. Li Huang, one of the company’s founders, is looking forward to “fruitful cooperation” with RAL members.

Stefan Thomann, the association’s managing director, said: “I am delighted to welcome yet another ambitious company in our association that is committed to quality and commercially successful with PCM. RuhrTech will undoubtedly manage to tap into new markets and applications where PCM can play a positive and beneficial role.”

The RAL Quality Association PCM was established in 2004 to develop standards for the PCM industry. Members include Axiotherm, Microtek Laboratories, Rubitherm, Croda Europe, va-Q-tec, PCM Technology, Global-Systems Europe, Sasol, Sunamp Ltd., Pluss Advanced Technologies and PureTemp LLC.

Because of the COVID-19 pandemic, the association’s next assembly will be held as a web conference on April 1. The association’s fall assembly is scheduled for Oct. 28, 2020, in Dusseldorf, Germany. More than a dozen representatives of member companies and monitoring institutes took part in last fall’s assembly. Here’s a group photo:

Back row, from left: Bernd Boiting, FH Münster/Axiotherm; Thomas Haussmann, ISE; Stefan Thomann, RAL Quality Association PCM managing director; Michael Brütting, ZAE; Andreas Laube, w&a; Gerard Oortman, PCM Technology.

Front two rows, from left: Jan van Acquoij, Pluss Advanced Technologies; Ben Welter, PureTemp LLC; Kate Fisher, Sunamp; Matthias Maywald, Sasol; Marco Auerbach, Croda; Thomas Wollheim, va-Q-tec; Harald Mehling, PCM consultant; Tim Riazzi, Microtek Laboratories; Esther Kieseritzky, Rubitherm; Claudia Friedrich, RAL Quality Association PCM.

PATENTS

Oil-in-water macro-emulsion process for forming solid gel beads

U.S. patent application 20200071586 (applicant Microtek Laboratories, Dayton, Ohio):

“Solid gel beads formed from a gel product of a 5 carbon to 60 carbon alkane phase change material, 5 carbon to 60 carbon alkene phase change material, or a combination thereof and a styrene-based polymer are homogeneous, has an uneven exterior surface, and a major axis length in a range of 1000 μm to 100 mm. Methods for making the solid gel bead include providing water having a preselected temperature based on a linear relationship to the melting point of a phase change material composition, mixing the phase change material composition with the styrene-based polymer at or below the preselected temperature with stirring to form a pulp, and mixing the pulp into the water with turbulent mixing while maintaining the temperature of the mixture at the preselected temperature.”

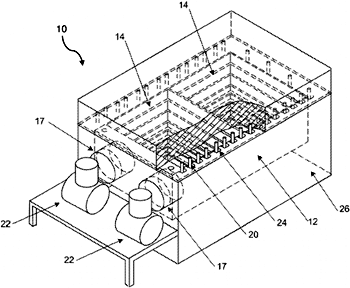

Thermal energy storage apparatus

U.S. patent application 20200088473 (applicant Climate Change Technologies Pty. Ltd., Wayville, Australia):

U.S. patent application 20200088473 (applicant Climate Change Technologies Pty. Ltd., Wayville, Australia):

“A thermal energy storage apparatus, including: a block of a heat-absorbing material, the block defining at least one receptacle and being a contiguous block of compressed sintered graphite; and a phase change material stored in the or each receptacle, the phase change material being one that expands as it cools, wherein separation of side walls of the or each receptacle progressively increases as they extend upwardly from the base, whereby as the phase change material solidifies and expands it is urged upwardly to reduce pressure applied to the heat-absorbing material.”

Tote handling for chilled or frozen goods

U.S. patent application 20200071076 (applicant Alert Innovation Inc., North Billerica, Mass.):

“An automated order fulfillment system is disclosed having different temperature zones and robots and containers capable of and/or configured to work in these different temperature zones.”

Modified dry ice system

U.S. patent application 20200072523 (inventors Chang Yup Seo, Woodridge, Ill.; Soujanya N. Jampala, Chicago, Ill.; Sameer H. Israni, Darien, Ill.; and Robert R. Sever, Arlington Heights, Ill.):

“This invention relates to a novel two-stage dry ice system for preserving perishable items during transport and methods thereof. The improved two-stage dry ice system includes dry ice and a phase change material specifically configured within a single and continuous holding volume with perishable items. Preservation of the perishable items for extended durations in comparison to other refrigeration techniques can be achieved as a result of the two-stage dry system having the ability to re-orient itself during transport.”

More U.S. patent applications:

Sanitary mask | Turbo machine starter-generator | Phase change nanoparticles for lithium-ion battery safety | Thermal management material and matrix | Breast prosthesis

IN BRIEF

• EnergyNest is one of 15 start-ups nominated as finalists of the Start Up Energy Transition Award 2020. EnergyNest’s thermal battery consists of steel cassettes with pipes encased in a special type of concrete. The Norwegian company announced earlier this year that an EnergyNest battery with a capacity of 6-8 MWh would be installed at a brick manufacturing plant in Austria.

• “T-History Simplified: Combining a Universal Standard with an IoT Strategy,” presented by Madison Hammerberg, product development engineering manager at CAVU Group, will be among the presentations at the Advancements in Thermal Management conference in Denver, Aug. 6-7, 2020.

• Croda now offers live chat on its CrodaTherm website, www.crodatherm.com. The “Chat with a Croda Expert” feature is designed to provide visitors with “instant support.”

• Terrafore Technologies of Minneapolis is one of 13 companies to be awarded a Launch Minnesota Innovation Grant from the state’s Department of Employment and Economic Development. The grants total $344,000; the amounts of individual grants were not disclosed. Terrafore is developing thermal energy storage to provide dispatchable solar power generation to the grid.

• RayGen Resources Pty. Ltd. of Australia has been awarded $3 million AUD toward a feasibility study for a 4 MW “solar hydro” power plant in Victoria. The money will come from the Australian Renewable Energy Agency. RayGen’s system extracts heat from solar panels and stores it in a water reservoir acting as a heat store. The hot reservoir is paired with cold reservoir chilled by electricity from the solar panels and the grid. The temperature difference powers an Organic Rankine Cycle engine to generate electricity with a round-trip efficiency of 70%.

• The Swedish thermal energy storage company Azelio has completed the installation of “a system that will store solar energy from what is claimed to be the world’s largest concentrated solar power plant project,” Energy Storage Journal reports. “The complex [in Morocco] is 2,500 hectares in size, and solar panels cover 1,000 square metres — which means it could potentially harvest a total of 2.6GW a year.” The system uses recycled aluminum as the heat storage material.

• Sunamp Ltd. of Edinburgh, Scotland, has signed a memo of understanding with Ripple Energy, a company that enables customers to part-own large-scale wind farms to power their homes. Under the agreement, Ripple will offer its customers Sunamp heat batteries, which use a specially formulated phase change material to store large amounts of energy from renewable and other sources and release it as heat to deliver hot water and space heating as needed.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Journal of Physics:• Corn oil phase change material (PCM) in frozen food cooling machine to improve energy efficiency

From Materials Today: Proceedings:

• Investigating thermal properties of Nanoparticle Dispersed Paraffin (NDP) as phase change material for thermal energy storage

From Energy:

• Effects of fluctuating thermal sources on a shell-and-tube latent thermal energy storage during charging process

From Solar Energy:

• Design, realization, and tests of a portable solar box cooker coupled with an erythritol-based PCM thermal energy storage

• Diversiform microstructure silicon carbides stabilized stearic acid as composite phase change materials

From International Journal of Thermofluids:

• Investigating the performance of a thermal energy storage unit with paraffin as phase change material, targeting buildings’ cooling needs: an experimental approach

From Journal of Cleaner Production:

• Energy and exergy analysis of wind farm integrated with compressed air energy storage using multi-stage phase change material

From Powder Technology:

• Effect of nano-SiC on thermal properties of expanded graphite/1-octadecanol composite materials for thermal energy storage

From Journal of Energy Storage:

• A multi-objective optimal design method for thermal energy storage systems with PCM: A case study for outdoor swimming pool heating application

• Reducing PV module temperature with radiation based PV module incorporating composite phase change material

• Numerical investigation on the effect of fin design on the melting of phase change material in a horizontal shell and tube thermal energy storage

From Journal of Thermal Analysis and Calorimetry:

• Characterization of form-stable phase-change material for solar photovoltaic cooling

From International Journal of Thermophysics:

• Thermophysical Properties of a Novel Nanoencapsulated Phase Change Material

From International Journal of Heat and Mass Transfer:

• Lattice Boltzmann simulation of forced convection melting of a composite phase change material with heat dissipation through an open-ended channel

• High power density thermal energy storage using additively manufactured heat exchangers and phase change material

From Energies:

• Evaluation of the State of Charge of a Solid/Liquid Phase Change Material in a Thermal Energy Storage Tank [pdf]

• Novel Simulation Algorithm for Modeling the Hysteresis of Phase Change Materials [pdf]

From Energy & Fuels:

• Novel shape-stabilized phase change materials based on paraffin/EPDM@graphene with high thermal conductivity and low leakage rate

From Polymers and Polymer Composites:

• Regulating phase-change temperatures of form-stable phase-change ternary composite fibrous membranes consisting of polystyrene nanofibers and fatty acid eutectics via co-electrospinning method

From Applied Energy:

• A design protocol for enhanced discharge exergy in phase change material heat battery

• Fabrication of heat storage pellets composed of microencapsulated phase change material for high-temperature applications

• A high-thermal-conductivity, high-durability phase-change composite using a carbon fibre sheet as a supporting matrix

From Journal of Building Engineering:

• Preparation and characterization of metal-organic framework /microencapsulated phase change material composites for indoor hygrothermal control

From Indoor and Built Environment:

• Numerical and experimental investigation on dynamic thermal performance of floor heating system with phase change material for thermal storage

From Applied Clay Science:

• A triply synergistic method for palygorskite activation to effectively impregnate phase change materials (PCMs) for thermal energy storage

From Chemical Engineering Journal:

• Lignin-fatty acid hybrid nanocapsules for scalable thermal energy storage in phase-change materials

From Construction and Building Materials:

• Phase change materials for pavement applications: A review

From Carbohydrate Polymers:

• Shape-stabilization of polyethylene glycol phase change materials with chitin nanofibers for applications in “smart” windows

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,500 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,500 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this month include Özgül Gök, assistant professor of chemical engineering at Hakkari University, Hakkari, Turkey; Nilesh Rane, research scholar at the Institute of Chemical Technology, Mumbai, India; Maria Kouidri, student intern at Laboratoires Merinal, Algiers, Algeria; Jinglei Yang, associate professor at the Hong Kong University of Science and Technology, Hong Kong; Gylen Odling, materials chemist at Sunamp Ltd., Edinburgh, United Kingdom; Emily Torrealba, mechanical designer at Henderson Engineers, New York, N.Y.; Ahmed Hassan, mechanical engineering student, University of Minnesota Duluth, Duluth, Minn.; Kanka Ghosh, post-doctoral researcher at I2M Bordeaux, University of Bordeaux, Bordeaux, France; Peter Mirabella, vice president for technical services at Q-Products & Services, Hazel Crest, Ill.; and Malek Nofal, product development, lithium-ion batteries, at AllCell Technologies, Chicago, Ill.