The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

COMPANY NEWS

Sunamp signs its first major UK contract

Sunamp Ltd. has signed a memo of understanding to supply its PCM-based heat batteries to Fischer Future Heat under an original equipment manufacturer contract. Sunamp, based in Edinburgh, Scotland, says the deal involves “many thousands” of units and will be worth seven figures as sales ramp up. Leicester-based Fischer began selling the product, dubbed the Aquafficient, in February.

In an email interview, Sunamp CEO Andrew Bissell filled in a few details on the deal.

In an email interview, Sunamp CEO Andrew Bissell filled in a few details on the deal.

Q: Can you tell me about the PCM aspects of this product?

A: “Sunamp’s success in making a super-stable (40,000+ cycles tested) salt hydrate PCM (very energy dense) at 58C and combining it (in a highly insulated, cuboid enclosure) with a very high power heat exchanger (high power, high flow rate hot water) made a whole class of heat battery devices possible. Not least electric water heaters, with about 4x the energy density of a classic electric hot water tank and 5+ gallon per minute performance. A key innovation (patent pending around the details) was to use electric elements immersed inside the PCM to melt the PCM and charge the heat battery.”

Q: What can you tell me about the manufacturing process?

A: “Because Aquafficient by Fischer Future Heat is based on Sunamp UniQ, it’s effectively been in production at Sunamp Factory for nearly a year.

“By going down this OEM white label route, Fischer Future Heat could hit the ground running with Aquafficient – which they did! Sunamp’s manufacturing has had to scale already this year from 75 units a month to 75 units a week, with 75 a day on the near horizon. This to keep up with exponentially rising combined demand from Fischer, other OEMs, and large housing and regeneration projects.

“We keep scaling production and the demand keeps outpacing us! We’re working really hard on scaling up production and appreciate our partners’ and their customers patience when they sometimes have to wait quite a number of weeks for the product they want.”

PHYSICS

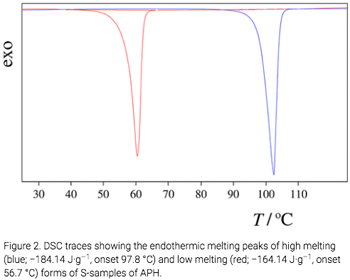

Have you ever seen a DSC quite like this?

More than 120 years ago, German chemist Emil Fischer said his lab had developed a crystal that seemed to defy the laws of physics. The solid form of acetaldehyde phenylhydrazone kept melting at two different temperatures. One batch might melt at 65° C; another at 100° C. Physics Today explains how the mystery was eventually solved:

“Colleagues and rivals at the time told him he must have made a mistake. Fischer didn’t think so. As far as he could tell, the crystals that melted at such different points were identical. A few groups in Britain and France repeated his work and got the same baffling results. But as those scientists died off, the mystery was forgotten, stranded in obscure academic journals published in German and French more than a century ago.

“Colleagues and rivals at the time told him he must have made a mistake. Fischer didn’t think so. As far as he could tell, the crystals that melted at such different points were identical. A few groups in Britain and France repeated his work and got the same baffling results. But as those scientists died off, the mystery was forgotten, stranded in obscure academic journals published in German and French more than a century ago.

“There it would probably have remained but for Terry Threlfall, an 84-year-old chemist at the University of Southampton, UK. Stumbling across Fischer’s 1896 paper in a library about a decade ago, Threlfall was intrigued enough to kick-start an international investigation of the mysterious crystal. Earlier this year in the journal Crystal Growth and Design, Threlfall and his colleagues published the solution: APH is the first recorded example of a solid that, when it melts, forms two structurally distinct liquids. Which liquid emerges comes down to contamination so subtle that it’s virtually undetectable.”

PATENTS

Polyurethane gel particles, methods and use in flexible foams

U.S. patent application 20190169390 (applicant Peterson Chemical Technology LLC, Austin, Texas):

“Combinations of open cell flexible foams with polyurethane gel particles, and methods of making the combinations are described using a variety of procedures. The open cell flexible foam may partially or wholly comprise polyurethane foam and latex foam. … The composition of claim 1 where the polyurethane gel particles contain at least one phase change material with a solid/liquid phase transition temperature range of from about −10° F. to about 220° F. (about −23° C. to about 104° C.).”

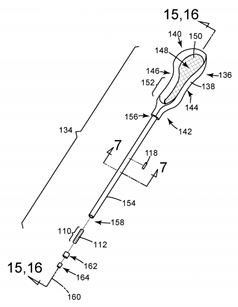

Heating a sports device

Heating a sports device

U.S. patent application 20190168091 (applicant Robert Marc Goldberg, Fayetteville, N.Y.):

“A sports device configured to generate thermal energy to warm surfaces. In one implementation, the sports device embodies a lacrosse stick with a shaft and head. The shaft includes a thermal core with a phase change material that can retain and dissipate heat over an extended period of time. … Suitable materials may maximize energy storage per unit volume/mass so as to add little weight to the lacrosse stick but still maintain surfaces at temperatures for extended periods. This feature can make the lacrosse stick comfortable for the player to grasp and to handle during game play and practice.”

Method and device for heating a mold

U.S. patent application 20190168432 (assignee Roctool, Le Bourget-du-Lac, France):

“A mold, particularly for injection molding, includes a shell defining a cavity delimiting a molding surface, a heat accumulator and inductor heater, configured to heat the heat accumulator. A receiving surface, which is a part of a surface of the shell other than the molding surface, is either exposed to or shielded from the heat of heat accumulator, to bring the entire molding surface to a predetermined temperature to inject the material into the cavity. … [The] heat accumulator comprises a phase change material. This embodiment makes it possible to store thermal energy in the latent phase change heat of said material.”

Composite construction panels and applications thereof

U.S. patent application 20190161967 (applicant Phase Change Energy Solutions, Asheboro, N.C.):

“In one aspect, composite construction materials are described herein. In some embodiments, a composite construction panel comprises a substrate layer, a cover layer separated from the substrate layer by one or more spacers, and at least one mat disposed between the substrate layer and the cover layer, wherein the mat comprises at least one phase change material disposed in at least one phase change region.”

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Energy:• Energy management of a household refrigerator using eutectic environmental friendly PCMs in a cascaded condition

• Use of encapsulated phase change materials in lightweight building walls for annual thermal regulation

• Screening of sugar alcohols and their binary eutectic mixtures as phase change materials for low-to-medium temperature thermal energy storage.

From Industrial and Engineering Chemistry Research:

• Biodegradable Polymeric Solid Framework-based Organic Phase Change Materials for Thermal Energy Storage

From Renewable Energy:

• Thermal Management and Uniform Temperature Regulation of Photovoltaic Modules Using Hybrid Phase Change Materials-Nanofluids System

• Polyethylene glycol/silica (PEG@SiO2) composite inspired by the synthesis of mesoporous materials as shape-stabilized phase change material for energy storage

From International Journal of Energy Research:

• Thermal buffering effect of a packaging design with microencapsulated phase change material

• Laboratory investigation on the use of thermally enhanced phase change material to improve the performance of borehole heat exchangers for ground source heat pumps

From IOP Conference Series: Materials Science and Engineering:

• Thermal properties of cool asphalt concrete containing phase change material

From International Journal of Advance Research and Innovation:

• Experimental Investigation of Thermal energy storage with phase changing material [pdf]

From Thermal Science and Engineering Progress:

• Experimental study on thermal storage and heat transfer performance of microencapsulated phase-change material slurry

From Journal of Molecular Liquids:

• Thermal conductivity modification of n-octanoic acid-myristic acid composite phase change material

From International Journal of Refrigeration:

• Experimental study of enhanced PCM exchangers applied in a thermal energy storage system for personal cooling

From Applied Thermal Engineering:

• Development of paraffinic phase change material nanoemulsions for thermal energy storage and transport in low-temperature applications

• Effect of micro encapsulated phase change material on the anti-dry-out ability of pulsating heat pipes

From Construction and Building Materials:

• Integrating phase change materials in construction materials: Critical review

From Solar Energy Materials and Solar Cells:

• Compatibility of vegetable oils with solid filler materials for thermocline thermal energy storage systems

• Novel paraffin/ethylene propylene diene monomer phase change latex with excellent stability and low viscosity

From Applied Materials and Interfaces:

• Natural Microtubule-Encapsulated Phase-Change Material with Simultaneously High Latent Heat Capacity and Enhanced Thermal Conductivity

From Applied Energy:

• System performance and economic assessment of a thermal energy storage based air-conditioning unit for transport applications

• Experimental investigation of a cementitious heat storage medium incorporating a solar salt/diatomite composite phase change material

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,475 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,475 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Prakash Ratha, head of product and technical services at Promethean Power Systems, Pune, India; Philipp Hilbert, product engineer at Auria Solutions GmbH, Hannover, Germany; Steven Harbauer, applications engineer at Ridgetop Group, San Bernardino, Calif.; Marcus Maier, postdoctoral scholar at Berkeley Education Alliance for Research in Singapore; Mariateresa Lettieri, research scientist at the Institute for Archaeological and Monumental Heritage, National Research Council, Rome, Italy; Robbie Ferguson, sales manager, Zip Water UK, Motherwell, United Kingdom; and Mi (Aimee) Lu, R&D associate staff member at Oak Ridge National Laboratory, Knoxville, Tenn. Mi writes:

“Recently, we submitted a concept paper to respond to BTO (building technology program) office FOA in developing bio-based PCMs for thermal energy storage. We were encouraged to develop a full proposal. Our idea is to utilize biocrude in bio-PCM development.”

Mi says ORNL is looking for industry partners to help develop the concept and share costs. For more information, see FY 2019 Buildings Energy Efficiency Frontiers & Innovation Technologies (BENEFIT) Funding Opportunity Announcement [pdf] or contact Lum1@ornl.gov.