The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

NEW PRODUCTS

PCM replacement cap keeps insulin pens at the proper temperature

TempraMed’s first-generation Vivi Cap1 fits over any type of insulin pen and adjusts constantly to keep the insulin at the higher end of room temperature. When the device is exposed to temperatures above 29° C, the bio-based PCM begins to absorb heat and change from solid to liquid. When the ambient temperature falls below 28° C, the PCM starts to return to its solid state, allowing it to regain its heat-absorbing property. A push of a button at the base allows the user to confirm that the insulin is at the proper temperature.

“We are not aware of similar products that are available on the market,” said Ron Nagar, TempraMed president and CEO. “Until now, most commonly used products for ‘keeping insulin cool’ use water evaporation technology, which requires frequent user intervention, and is not effective in closed bags (where medication is commonly carried) or in humid environments.

“With the insulation and PCM we use, we offer very compact solutions (slightly larger than current insulin pen cap) which can maintain the proper conditions for time durations that are typically longer than the exposure expected during daytime or when outdoors, and allow recovery during the night or when back indoors, without user intervention.”

TempraMed is based in Tel Aviv with an office in Washington State. The products are manufactured in Israel.

The FDA– and CE-registered Vivi Cap1 is available now on the company’s website, www.my-vivi.com, at a cost of $49.90. The next generation of Vivi products will be available in the fall: Vivi Epi for epinephrine pens; Vivi Vial for insulin vials; and Vivi Cool 8° C and Vivi Vial 8° C for storing insulin at lower temperatures.

Nagar said TempraMed is working with several distributors to make the products widely available, including retail chains.

PATENTS

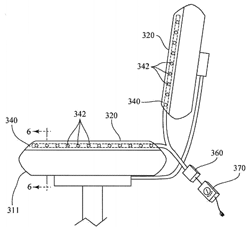

Support cushion cover assemblies for removing heat and humidity

U.S. patent 20170150822 (applicant Tempur-Pedic Management LLC, Lexington, Ky.):

“A support cushion cover assembly for removing humidity and heat from a contact surface of a support cushion is provided. The support cushion cover assembly comprises a support cushion cover that includes an upper panel having a top surface, a bottom surface, and a middle spacer layer positioned between the top surface and the bottom surface. The support cushion cover further includes an amount of hygroscopic material and at least one flexible tube that defines a plurality of fenestrations. Each fenestration is in fluid communication with the middle spacer layer of the upper panel. An air pump is further included in the cover assembly and is operably connected to the flexible tube, such that an amount of air is delivered into the flexible tube and the middle spacer layer of the cover. Methods for removing humidity from a contact surface of a support cushion are also provided.”

“A support cushion cover assembly for removing humidity and heat from a contact surface of a support cushion is provided. The support cushion cover assembly comprises a support cushion cover that includes an upper panel having a top surface, a bottom surface, and a middle spacer layer positioned between the top surface and the bottom surface. The support cushion cover further includes an amount of hygroscopic material and at least one flexible tube that defines a plurality of fenestrations. Each fenestration is in fluid communication with the middle spacer layer of the upper panel. An air pump is further included in the cover assembly and is operably connected to the flexible tube, such that an amount of air is delivered into the flexible tube and the middle spacer layer of the cover. Methods for removing humidity from a contact surface of a support cushion are also provided.”

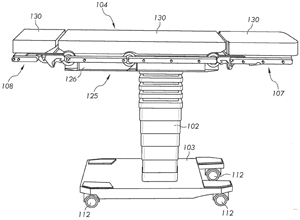

Person support system with cooling features

U.S. patent 20170135884 (applicant Hill-Rom Services Inc., Batesville, Ind.):

“Embodiments provide a person support system including support pads having cooling features. According to one embodiment, a person support system may include a longitudinal frame comprising at least one side rail. A support pad may be positioned on the longitudinal frame. The support pad may comprise a thermally conductive core portion comprising a support matrix and at least one thermally conductive element. … The thermally conductive core portion may be constructed from different phase change materials (or even different combinations of phase change materials) to achieve different degrees of cooling.”

“Embodiments provide a person support system including support pads having cooling features. According to one embodiment, a person support system may include a longitudinal frame comprising at least one side rail. A support pad may be positioned on the longitudinal frame. The support pad may comprise a thermally conductive core portion comprising a support matrix and at least one thermally conductive element. … The thermally conductive core portion may be constructed from different phase change materials (or even different combinations of phase change materials) to achieve different degrees of cooling.”

Phase change and/or reactive materials for energy storage/release

U.S. patent application 20170141724 (applicant GlassPoint Solar Inc., Fremont, Calif.):

“A method for delivering heat to a subsurface location, comprising: transferring solar energy to a working fluid via multiple solar collectors; directing the working fluid through a loop to at least partially transfer energy from the working fluid to a subsurface heating well, wherein the loop at least partially extends through the subsurface heating well, and wherein the subsurface heating well contains a thermal energy storage substance (TESS) positioned between the working fluid and an outer casing of the subsurface heating well; and controlling a flow of the working fluid to cause the TESS to undergo at least a partial phase change at least one phase change temperature or a partial chemical change at at least one chemical change temperature.”

IN BRIEF

• Thermal Energy Service Solutions, maker of a PCM-based “plug-and-chill” refrigeration system for delivery trucks, is profiled in this month’s issue of Forbes India. The system’s heat exchanger is designed to keep the refrigerator on the truck within the optimal temperature range for a full day’s operation without drawing power from the engine. The heat exchanger can be fully charged in about six hours at any power outlet.

• C-Therm Technologies will be among the exhibitors the Techtextil North America trade show in Chicago June 20-22. The company will demonstrate its non-destructive TCi Property Analyzer, which is designed to characterize the thermal performance (the “warm feel” or “cool touch”) of textiles, fabrics and apparels.

• Terrafore Technologies of Minneapolis is one of seven small businesses recently selected to collaborate with researchers at Argonne National Laboratory as part of the Department of Energy‘s Small Business Vouchers program. Terrafore and Argonne will test the reliability of phase change salt capsules for a compact high-temperature thermal energy storage system for concentrated solar power.

• SpecialChem is offering an online course titled “How to Search & Map U.S. Patents for Patentability.” The 90-minute course, scheduled for June 28, is designed to for R&D people “looking to avoid patent infringement by enhancing their patent searching and mapping skills.” The cost for three attendees on one connection is 300 euros.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Applied Thermal Engineering:

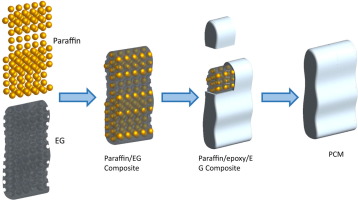

• Novel shape stabilized phase change material based on epoxy matrix with ultrahigh cycle life for thermal energy storage

• Solid Thermal Storage with PCM Materials. Numerical Investigations

• Investigation of specific heat and latent heat enhancement in hydrate salt based TiO2 nanofluid phase change material

From Solar Energy Materials and Solar Cells:

• A new flame retardance strategy for shape stabilized phase change materials by surface coating

• Thermal properties and thermal conductivity enhancement of composite phase change materials using myristyl alcohol/metal foam for solar thermal storage

From Applied Energy:

• Graphene or h-BN paraffin composite structures for the thermal management of Li-ion batteries: A multiscale investigation

From Energy Procedia:

• Experimental and Numerical Study on Energy Performance of Buildings Integrated with Phase Change Materials

• Effect of Supercooling on the Solidification Process of the Phase Change Material

• Evaluation on Performance of a Phase Change Material Based Cold Storage House

• Experimental Investigation of a Spiral Tube Embedded Latent Thermal Energy Storage Tank Using Paraffin as PCM

From Journal of Cleaner Production:

• Modeling and investigation of high temperature phase change materials (PCM) in different storage tank configurations

From Applied Clay Science:

• Lauric acid/modified sepiolite composite as a form-stable phase change material for thermal energy storage

From Construction and Building Materials:

• Investigation on thermal and mechanical characteristics of concrete mixed with shape stabilized phase change material for mix design

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than a thousand of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Martin Heinemann, head of customer service at va-Q-tec AG, Würzburg, Germany; Nandi Lwin, who is pursuing a master’s degree in materials science and engineering at Mahidol University, Bangkok, Thailand; Francisco Tamayo, a student at the Institute of Renewable Energy, National Autonomous University of Mexico, Morelos, Mexico; and Wulf Luebbe, planning and optimization manager, Sasol Wax GmbH, Hamburg, Germany.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Martin Heinemann, head of customer service at va-Q-tec AG, Würzburg, Germany; Nandi Lwin, who is pursuing a master’s degree in materials science and engineering at Mahidol University, Bangkok, Thailand; Francisco Tamayo, a student at the Institute of Renewable Energy, National Autonomous University of Mexico, Morelos, Mexico; and Wulf Luebbe, planning and optimization manager, Sasol Wax GmbH, Hamburg, Germany.