The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

AEROSPACE

Cubesat propulsion concept wins $225,000 NSF grant

A Cubesat propulsion system that uses phase change material to store solar thermal energy for use when needed has been awarded a $225,000 National Science Foundation SBIR grant. The ThermaSat concept, developed by Howe Industries of Tempe, Ariz., is designed to provide propulsion for a typical 15kg cubcubesat for 10 years.

Cubesats are tiny satellites — weighing as little as 200 grams — that orbit close to Earth’s atmosphere. They are cheaper to develop and launch than larger satellites. Cubesats have a wide range of purposes, including the collection of mapping and weather data. More than 1,100 have been successfully deployed.

Troy Howe, owner of Howe Industries, answered questions about the ThermaSat propulsion system.

Q: How long has your company been working on the concept?

A: “We have been working on this topic for only about a year in preparation for our NSF proposal, but have experience with optical systems and phase change materials going back about five years.”

Q: Can you briefly describe how the system works?

A: “The ThermaSat works by heating liquid water propellant to high temperature steam using incident sunlight. Normally, it is difficult to reach high enough temperatures to use water as propellant, but our optical filtration system is designed to reject long wavelengths of light and only transmit short wavelengths- similar to the greenhouse effect. The phase change materials in the thermal capacitor store the solar energy over a period of hours and then heat the propellant during a ‘burn’ phase.

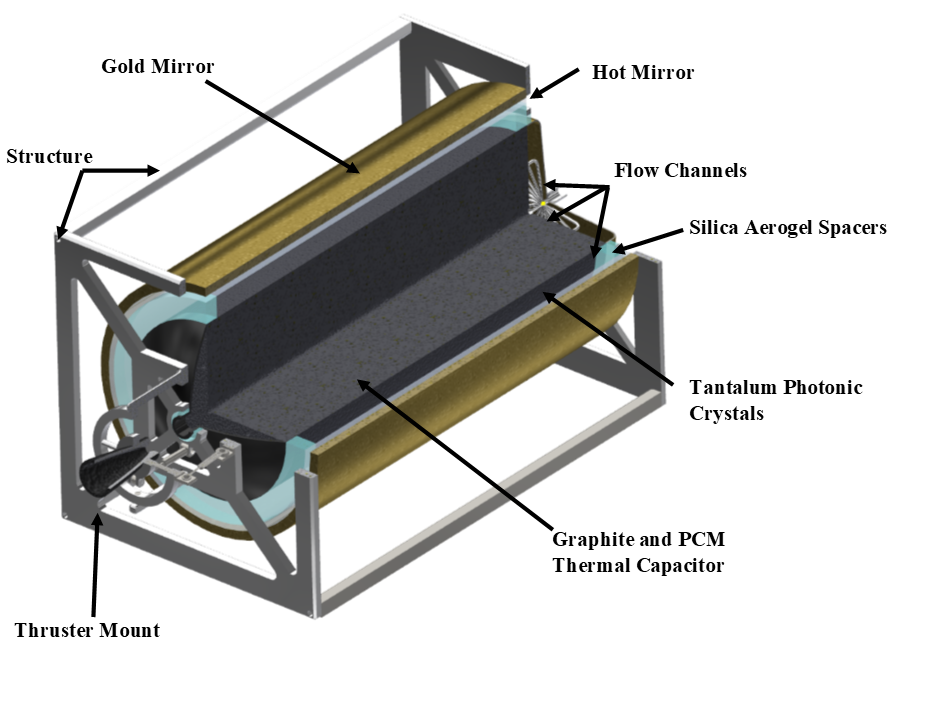

“The PCM will be distributed throughout a graphite matrix in the form of small beads. Flow channels will run axially down the length of the cylinder for the propellant to pass through. The design is based loosely on the old NERVA fuel elements from the nuclear rocket program in the 1970s, with the UC kernels being replaced with our PCM. The drawing here shows a cutaway of the thermal capacitor surrounded by the optical system.

“The PCM will be distributed throughout a graphite matrix in the form of small beads. Flow channels will run axially down the length of the cylinder for the propellant to pass through. The design is based loosely on the old NERVA fuel elements from the nuclear rocket program in the 1970s, with the UC kernels being replaced with our PCM. The drawing here shows a cutaway of the thermal capacitor surrounded by the optical system.

“The system is very conceptual at this point and has not been tested, although the propulsion characteristics are well understood. Our task at this point is to show that the optical system works as predicted and can reach the desired temperatures. Phase II will address the effects of a vacuum environment on a prototype.”

Q: What type of PCM is used?

A: “We chose a salt (80LiOH+20LiF) as our PCM, it melts at 700K and has a latent heat of fusion of 1163 J/g. The material was selected based on a study performed by NASA in 1986 on space energy storage. The paper was called ‘Technology for Brayton-Cycle Space Powerplants Using Solar and Nuclear Energy’ by Robert English.””

Q: How much PCM would be used in a system powering a typical Cubesat?

A: “The standard design includes 0.62 kg of PCM. “

Q: Are you working with any Cubesat manufacturers at this point?

A: “We received letters of interest from Pumpkin Space Systems, Aster Labs, and Arizona State University. They all expressed interest in having a safe and reliable Cubesat propulsion system but we have not formally formed collaboration with any manufacturers at this point.”

Q: How will you use the NSF SBIR grant?

A: “Our goals for this topic include demonstrating the optical system in a lab bench test, fabricating photonic crystals, and performing computational analysis on the thermal, structural, and propulsion systems.”

Q: What’s the next major step in commercializing the system?

A: “Our commercialization strategy right now is to build a functioning prototype and demonstrate operation on earth. From that point we will aim to do a flight test which performs a set of orbital maneuvers and successfully de-orbits itself. From there we will work with Cubesat manufacturers to move forward.”

Q: What excites you most about this project?

A: “We are excited about how near term and effective this technology will be for the upcoming Cubesat revolution. We hope to provide a safe, reliable, and effective propulsion solution that can be used with thousands of different satellites and drastically increase the performance of new technologies in space in the timeframe of just a few years.”PATENTS

Temperature controlled product shipper

U.S. patent application 20200033045 (applicant Packaging Technology Group Inc., Fall River, Mass.):

“A temperature-controlled product shipper includes a phase change material bladder which can be filled at the point of packaging. The shipper includes an internal product box and an outer box where the product box is received within the outer box. The phase change material bladder is received within a cavity defined between the outer surface of the product box and the inner surface of the outer box. The shipper may also include an insulated liner which is received between the product box and the bladder.”

Device and method for drug delivery

U.S. patent application 20200038600 (applicant Insuline Medical Ltd., Jerusalem, Israel):

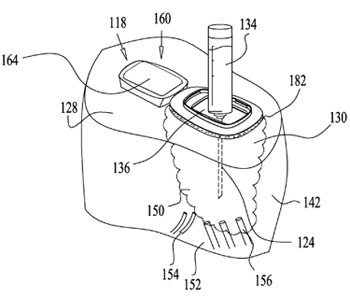

“A drug delivery control apparatus (e.g. a treatment apparatus) may be configured to control an amount of drug contained in a drug depot delivered or otherwise perfused or diffused into the circulatory system of a patient comprising a cooling element configured for cooling a treatment area by removing heat from the treatment area. The cooling element may be arranged above or near the treatment area. A heat disposal assembly is in thermal communication with the cooling element and configured for directing the removed heat to a heat zone away from the treatment area. A power source, a controller and a housing may be configured to at least partially house at least the cooling element and the heat disposal assembly. … the heat disposal assembly comprises a phase change material configured to absorb at least some heat from the treatment area.”

“A drug delivery control apparatus (e.g. a treatment apparatus) may be configured to control an amount of drug contained in a drug depot delivered or otherwise perfused or diffused into the circulatory system of a patient comprising a cooling element configured for cooling a treatment area by removing heat from the treatment area. The cooling element may be arranged above or near the treatment area. A heat disposal assembly is in thermal communication with the cooling element and configured for directing the removed heat to a heat zone away from the treatment area. A power source, a controller and a housing may be configured to at least partially house at least the cooling element and the heat disposal assembly. … the heat disposal assembly comprises a phase change material configured to absorb at least some heat from the treatment area.”

Device and method for precise temperature control of beverages

U.S. patent application 20200037823 (inventor David Pensak, Wilmington, Del.):

“Devices that utilize phase change materials to maintain objects, such as beverage containers, within a precise temperature range for extended periods, without the need for ice, open flames, or mechanical heating or refrigeration, are disclosed.”

Portable apparatus using PCM to create temperature stable environment

U.S. patent application 20200041147 (assignee Fruition LLC, Lexington, Mass.):

“A carrying case utilizes a layer of phase change materials and a thermal insulation layer in order to provide a temperature-stabilized environment for enclosed payloads such as musical instruments during transport through an environment in which temperatures differ greatly from those to which they are normally exposed. In one aspect, the phase change materials and thermal insulation provide an extended period of temperature constancy, without the addition of either active thermal control or excessively bulky insulation.”

IN BRIEF

• Ice Energy, the Santa Barbara, Calif., company that made and distributed ice-based thermal energy storage systems, has filed for bankruptcy. The company’s Ice Bear system makes ice at night when demand for electricity is low and capacity is abundant. During the day, the stored ice is used to provide cooling. Details of the Chapter 7 bankruptcy, filed in December, are sparse. The company’s website is no longer active. Over the years, Ice Energy had won several major energy storage and distribution contracts with utilities, and had begun marketing a smaller version of the Ice Bear system aimed at retail customers.

• Ice Energy, the Santa Barbara, Calif., company that made and distributed ice-based thermal energy storage systems, has filed for bankruptcy. The company’s Ice Bear system makes ice at night when demand for electricity is low and capacity is abundant. During the day, the stored ice is used to provide cooling. Details of the Chapter 7 bankruptcy, filed in December, are sparse. The company’s website is no longer active. Over the years, Ice Energy had won several major energy storage and distribution contracts with utilities, and had begun marketing a smaller version of the Ice Bear system aimed at retail customers.

• Viking Cold Solutions has an opening for a chemical/thermal engineer in Houston. The engineer will “conduct research in Thermal Science, Storage/Heat Transfer and Phase Change Materials (PCM) for low temperature applications.”

• Axiom Exergy has secured more than $1 million in orders for the Axiom Cloud, a software platform that helps manage energy consumption in supermarkets and cold storage facilities that use the company’s PCM-powered thermal storage systems.

• Registration is open for the 23rd Microencapsulation Industrial Convention to be held June 8-11 in Rotterdam, Netherlands.

• EnergyNest will install a large thermal energy storage battery at a Senftenbacher brick factory in Austria. The system will temporarily store excess energy in the form of hot air from a tunnel furnace. The stored heat be converted to steam and later reused in production.

• Devan Chemicals, the Belgium-based developer of finishing technologies for textiles, introduced its Tones of Cool Bio technology at the Heimtextil trade show in Frankfurt, Germany, last month. The technology “stimulates the textile to dissipate redundant heat from the body and to instantly reduce the body temperature,” the company says. The phase change materials “are derived from sustainable, natural sources.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Energy & Fuels:• Hierarchically Porous PVA Aerogel for Leakage-Proof Phase Change Materials with Superior Energy Storage Capacity

From Energy and Built Environment:

• Investigation of heat transfer of a building wall in the presence of phase change material (PCM)

From Solar Energy Materials and Solar Cells:

• Guidelines for phase change material selection based on a holistic system model

• Development of a stable inorganic phase change material for thermal energy storage in buildings

• Enhanced thermal properties of hydrate salt/poly (acrylate sodium) copolymer hydrogel as form-stable phase change material via incorporation of hydroxyl carbon nanotubes

From Renewable Energy:

• Thermal performance analysis of thermocline combined sensible-latent heat storage system using cascaded-layered PCM designs for medium temperature applications

• Emerging paraffin/carbon-coated nanoscroll composite phase change material for thermal energy storage

• Climate response of a BiPV façade system enhanced with latent PCM-based thermal energy storage

From Applied Thermal Engineering:

• Analytical and numerical sizing of phase change material thickness for rectangular encapsulations in hybrid thermal storage tanks for residential heat pump systems

From Applied Energy:

• A high heat storage capacity form-stable composite phase change material with enhanced flame retardancy

• Shape-stable thermo-responsive nano Fe3O4/fatty acids/PET composite phase-change material for thermal energy management and saving applications

From Energy:

• Low cost and eco-friendly wood fiber-based composite phase change material: Development, characterization and lab-scale thermoregulation performance for thermal energy storage

From Composites Science and Technology:

• A phase change material encapsulated in a mechanically strong graphene aerogel with high thermal conductivity and excellent shape stability

From Polymer:

• Preparation of microencapsulated phase change materials (mPCMs) by using RAFT synthesized well-defined surfactants

From Polymer Engineering & Science:

• Form‐Stabilized Polyethylene Glycol/Palygorskite Composite Phase Change Material: Thermal Energy Storage Properties, Cycling Stability, and Thermal Durability

From Chemical Engineering Journal:

• Porous MgO-stabilized CaO-based powders/pellets via a citric acid-based carbon template for thermochemical energy storage in concentrated solar power plants

From International Journal of Energy Research:

• Designing behenic acid microcapsules as novel phase change material for thermal energy storage applications at medium temperature

From Recent Advances in Chemical Engineering:

• Experimental Study on PCM-Based External Wall Cladding for Energy Efficient Buildings

From SAE International:

• Transient Simulation of Heat Exchangers with Phase Change Material

From Materials Today: Proceedings:

• SWOT analyses of high-temperature phase change materials for thermal energy storage

From International Journal of Heat and Mass Transfer:

• Molecular dynamics simulation of nanoparticle effect on melting enthalpy of paraffin phase change material

From Solar Energy:

• Assessment of energy and cost analysis of packed bed and phase change material thermal energy storage systems for the solar energy-assisted drying process

• Performance analysis of solar assisted heat pump coupled with build-in PCM heat storage based on PV/T panel

• Thermo-optically responsive phase change materials for passive temperature regulation

From IOP Conference Series: Earth and Environmental Science:

• Energy storage systems review and case study in the residential sector

From Advances in Mechanical Engineering:

• Thermo-economic Study of Phase Change Materials (PCMs) for Thermal Energy Storage

From RSC Advances:

• Synthesis of monolithic shape-stabilized phase change materials with high mechanical stability via a porogen-assisted in situ sol–gel process

From Journal of Energy Storage:

• Palm oil-based bio-PCM for energy efficient building applications: Multipurpose thermal investigation and life cycle assessment

• Research progress in nucleation and supercooling induced by phase change materials

• Evaluation of volume change in phase change materials during their phase transition

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,500 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,500 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This month we welcome Jonni King, director/owner at King Trade Solutions Ltd., Shanghai, China; Ismail Gürkan Demirkiran, research assistant at Izmir Institute of Technology, Turkey; Hanseop Shin, executive consultant at Amotech Co. Ltd., Seoul, South Korea; Andrew Gibson, quality manager and cold chain engineer at CoolPac, Eumemmerring, Australia; Angel Quintana Lopez, student at Escuela Superior Politécnica del Litoral, Guayaquil, Ecuador; and Heng Li, materials scientist, Charlotte, N.C.