The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

ACADEMIC RESEARCH

PureTemp shows energy-saving potential in EnergyPlus simulations

In EnergyPlus simulations using hysteresis data, the integration of PureTemp phase change materials in a building’s suspended ceiling tiles showed potential savings in cooling energy ranging from 5.5 percent to 37.4 percent.

The PCM modeling research, conducted at University of Manitoba, also found a reduction in “discomfort hours” from 10 percent to 29 percent, depending on the zone and PCM type.

The PCM modeling research, conducted at University of Manitoba, also found a reduction in “discomfort hours” from 10 percent to 29 percent, depending on the zone and PCM type.

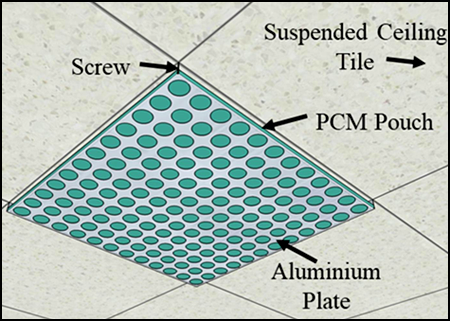

The researchers set out to investigate the feasibility of integrating PCMs within a suspended ceiling using the hysteresis method in EnergyPlus 8.9. The hysteresis effect, wherein a PCM has different melting/freezing temperature curves, complicates the simulation of PCM use in buildings. The EnergyPlus modeling software was updated in 2017 to include the effect of hysteresis.

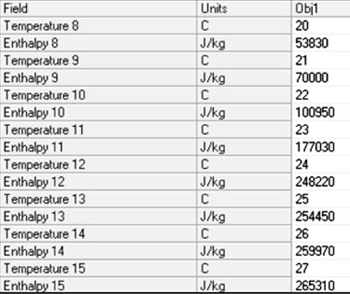

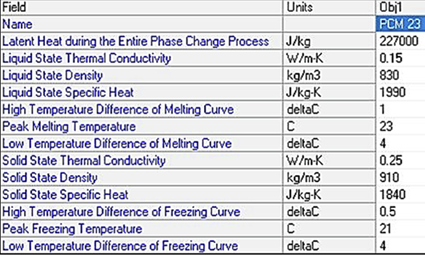

Minneapolis-based PureTemp LLC provided the researchers with the thermo-physical properties of PCMs required for modeling in EnergyPlus. Five types of PCMs, namely PCM20 (PureTemp 20), PCM21, PCM22, PCM23 (PureTemp 23), and PCM24, were tested and analyzed. The melting and freezing temperatures of the five PCMs fall within the thermal comfort range and operation of the HVAC system of the building the researchers chose as a case study: the University of Manitoba’s new Stanley Pauley Engineering Building.

The number of each PCM represents the material’s peak melting temperature in degrees Celsius. The theoretical properties of PCM21, PCM22 and PCM24 were derived from the actual properties of PureTemp 20, PureTemp 23 and PureTemp 25.

The number of each PCM represents the material’s peak melting temperature in degrees Celsius. The theoretical properties of PCM21, PCM22 and PCM24 were derived from the actual properties of PureTemp 20, PureTemp 23 and PureTemp 25.

One of the study’s authors, Dr. Miroslava Kavgic, right, is an assistant professor of civil engineering at the university. She answered questions about the research by email.

Q: What do you think is the most important finding, as far as impact on manufacturers of PCMs and PCM products?

A: “The findings of our research study suggest a promising future for the applications of PCMs in buildings located in cold climates. Furthermore, our study showed that in addition to already proven cooling energy-saving potential, PCMs can be very efficient in reducing heating energy demand. As a result, the findings from our study can increase application of PCMs in buildings located in the dominant heating climates, and therefore increase the demand for these unique building materials. We also hope that higher demand for PCMs will bring down their price which currently hinders the more extensive application of PCMs in areas with the lower energy prices such as Manitoba.”

Q: Why did you choose to use PureTemp data? Was there a preference to use a biobased PCM? Or was data on other products hard to obtain?

|

| EnergyPlus PCM model, enthalpy-temperature method |

Q: Given the impact of a PCMs hysteresis the final simulation results, is there a standard you’d like the industry to establish for consistent data from the PCM manufacturers?

|

| EnergyPlus PCM model, hysteresis method |

A: “Consistent data from the PCM manufacturers would increase confidence in the modeling results, and this applies to both hysteresis and temperature-enthalpy methods. Moreover, the consistent PCM properties could also be beneficial for the manufacturers as they will allow the end-user to test multiple PCMs and purchase several different materials for real-world implementation. This is particularly important considering the need for numerical analysis before the real-world implementation due to both complex behavior of PCMs and their relatively high price. The sensitivity analysis of the hysteresis input parameters suggests that manufacturers should pay partial attention to the parameters that have high impact on the simulation results.”

Q: For future work, is there interest in comparing the same PCM measured with different methods, such as T-history and DSC?

A: “The t-history method is relatively inexpensive and straightforward to measure the phase-change enthalpy of PCM products using considerably larger sample sizes compared to DSC, and therefore for non-uniform PCMs it is a good testing alternative to DSC.”

Table 3. Thermo-physical properties of the tested PCM:

| Hysteresis properties | PCM20 | PCM21 | PCM22 | PCM23 | PCM24 |

| Latent heat during the entire phase change process (J/kg) | 171,000 | 189,000 | 208,000 | 227,000 | 207,000 |

| Peak melting temperature (°C) | 20 | 21 | 22 | 23 | 24 |

| Peak freezing temperature (°C) | 18 | 19 | 20 | 21 | 22 |

| Liquid-state thermal conductivity (W/(m∙K)) | 0.14 | 0.143 | 0.146 | 0.15 | 0.15 |

| Solid-state thermal conductivity (W/(m∙K)) | 0.23 | 0.236 | 0.243 | 0.25 | 0.25 |

| Liquid-state density (kg/m3) | 680 | 730 | 780 | 830 | 840 |

| Solid-state density (kg/m3) | 950 | 936 | 923 | 910 | 930 |

| Liquid-state specific heat (J/(kg∙K)) | 2150 | 2096 | 2043 | 1990 | 2140 |

| Solid-state specific heat (J/(kg∙K)) | 2070 | 1993 | 1916 | 1840 | 1915 |

The full version of the paper is available here through the end of September 2019:

https://authors.elsevier.com/a/1ZZ3u4r6KuzlE4

PATENTS

Climate control system with thermal storage device

U.S. patent application 20190264933 (applicant Emerson Climate Technologies Inc., Sidney, Ohio):

“A climate-control system includes a working fluid circuit and a storage tank. The working fluid circuit has a first compressor, a first heat exchanger, a second heat exchanger, a flash tank, and a third heat exchanger. The first heat exchanger receives working fluid discharged from the first compressor. The flash tank is disposed downstream the first heat exchanger and includes an inlet and first and second outlets. The first outlet provides working fluid to the third heat exchanger disposed between the flash tank and the first compressor. The second outlet provides working fluid to the first compressor. The storage tank contains phase-change material that is thermally coupled with the second heat exchanger of the working fluid circuit.”

In situ expandable tubulars

U.S. patent application 20190264543 (applicant Terves Inc., Euclid, Ohio):

“Expandable tube members that are fabricated from a composite material that includes a structural plastic, which structural plastic includes phase change materials that undergo a permanent expansion upon exposure to wellbore conditions. This permanent expansion of the structural plastic causes the expandable tube member to expand radially and/or longitudinally without the use of an expansion tool. The expandable tube member can be used to control fluid loss, patch wells, stabilize a formation in a wellbore, enhance flow, provide sand screening, and repair damaged pipes, casings, or liners.”

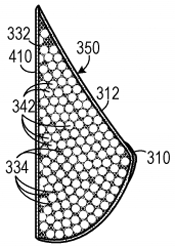

Breast prostheses with phase change material

U.S. patent application 20190262143 (inventors Robert Halley, Atlanta, Georgia; Amanda Wollnick, Doraville, Georgia; and Joachim Rechenberg, Nussdorf Am Inn, Germany):

U.S. patent application 20190262143 (inventors Robert Halley, Atlanta, Georgia; Amanda Wollnick, Doraville, Georgia; and Joachim Rechenberg, Nussdorf Am Inn, Germany):

“In a method of making a breast prosthesis for use by a wearer having a body temperature, a plurality of dissolvable beads is placed into an open back of a breast-shaped mold. The open back of the mold is sealed. A suspension of an uncured silicone rubber liquid and a plurality of phase change material pellets is injected into the mold around the beads. The uncured silicone rubber is allowed to cure, thereby forming a breast shape. The phase change material has a latent heat of fusion at a melting point so as to remove heat from the wearer when the body temperature is at least at the melting point. The breast shape is removed from the mold and the dissolvable beads are dissolved from the breast shape.”

IN BRIEF

• Engerati.com explains how SaltX Technology‘s energy storage pilot project at a Vattenfall power plant is feeding heat into a district heating system in Berlin.

• Pluss Advanced Technologies of Gurgaon, India, is encouraging women who are looking to re-enter the workforce to apply for openings at the PCM maker. “Pluss welcomes women who have temporarily taken a break and are looking forward to make their mark again,” Pluss says in a popup window that greets visitors to the company’s website, pluss.co.in. Pluss is seeking candidates for positions in R&D, sales, marketing and corporate communications. For more information, write to jobs@pluss.co.in.

• Energy Source and Distribution Magazine explains how SA Water and 1414 Degrees got the world’s first commercial pilot of a biogas thermal energy storage system up and running in less than two years. 1414 adapted its molten silicon energy storage system to harness biogas generated at the utility’s Glenelg Wastewater Treatment Plant in South Australia and convert it to electrical power.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Cellulose:• Microencapsulated organic coconut oil as a natural phase change material for thermo-regulating cellulosic fabrics

From Journal of Physics: Conference Series:

• Numerical and experimental investigation of melting process in spherical PCM capsule used for low-temperature thermal energy storage systems

From Energy:

• Synthesis and characterization of mixed alkanes microcapsules with phase change temperature below ice point for cryogenic thermal energy storage

• Preparation of Low Hydration Heat Cement Slurry with Micro-encapsulated Thermal Control Material

From Applied Thermal Engineering:

• A Three-Dimensional Numerical Investigation of a Novel Shallow Bore Ground Heat Exchanger Integrated with Phase Change Material

From Polymer Science:

• Preparation of Phase Change Microcapsules with Inorganic/Polymer Hybrid Shell Through a “Two-Step” Reaction

From Solar Energy:

• Improved thermal energy storage for nearly zero energy buildings with PCM integration

From Thermal Science and Engineering Progress:

• A theoretical and experimental study of a TBAB salt hydrate based cold thermal energy storage in an air conditioning system

From Journal of Energy Storage:

• A Review of Phase Change Materials for the Thermal Management and Isothermalisation of Lithium-Ion Cells

From Energy Conversion and Management:

• Experimental performance evaluation of a novel designed phase change material integrated manifold heat pipe evacuated tube solar collector system

From Renewable and Sustainable Energy Reviews:

• Corrosion mechanisms in molten salt thermal energy storage for concentrating solar power

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,500 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,500 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Adam Valmoro, regional director at Viking Cold Solutions Inc., Petaluma, Calif.; Adiseshakarthik C, thermal engineer at Ingersoll Rand, India; and Feng Yu Hoe, PCM market analyst at Croda, Singapore.