The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

APPAREL

Wheelchair athletes will put PCM cooling vest to the test in Rio

Canada’s wheelchair rugby athletes will keep their cool at the Paralympic Games in Brazil next month, thanks to a PCM cooling vest developed by two recent graduates of Kwantlen Polytechnic University in British Columbia.

Jaymes Williams and Laura Hutchison designed the vest to address a problem faced by many athletes with spinal cord injuries: regulating body temperature. Quadriplegics have limited ability to sweat and are prone to overheating during rigorous physical activity. And wheelchair rugby is perhaps the most physically demanding sport in the Paralympics. Players race their wheelchairs up and down a court, working together to advance a ball – or prevent it from being advanced – over a goal line. Violent collisions are common in the sport, which was originally called “murderball.” The action is fast, the competition intense. In short: It gets hot out there.

Williams began working on the vest in 2014 as part of a design engagement course at KPU. He met with wheelchair rugby athletes and found they typically use cold drinks, misters and wet towels to cool down during breaks in the action. The athletes had tried various cooling vests and found them lacking.

After meeting with experts at the Canadian Sports Institute, Williams began work on a cooling vest designed to meet the needs of wheelchair athletes. He teamed up with Hutchison to refine the concept. The pair traveled to Toronto to observe the Canadian team in action at the 2015 Parapan Am Games. They traveled to Hanoi to work with Maxport JSC, a Vietnamese company that develops products for Nike, Adidas, Under Armour, Lululemon and other makers of sports apparel. Maxport provided assistance in exploring PCM containment options.

In April, the institute asked Williams and Hutchison to produce a set of eight cooling vests in time for the Rio Paralympics. Final touches are being applied to the vests this week. The Canadian team, ranked fourth in the world, will begin the hunt for gold on Sept. 14, facing off against the host nation, Brazil.

In April, the institute asked Williams and Hutchison to produce a set of eight cooling vests in time for the Rio Paralympics. Final touches are being applied to the vests this week. The Canadian team, ranked fourth in the world, will begin the hunt for gold on Sept. 14, facing off against the host nation, Brazil.

The athletic-looking vest weighs about 2.5 kilograms. It has a coated taffeta shell, poly-cotton lining, hook-and-loop closures and phase change material contained in polyurethane film. The biobased PCM, PureTemp 12, is made by Entropy Solutions. The PCM has a peak melting point of 12° C (54° F), a temperature ideal for absorbing excess body heat without causing discomfort or muscle cramps.

Fully charged vests provide about two hours of cooling relief to athletes, who wear them during warmups and on the sidelines.

What’s next for the vest?

“We’ve already had interest from people around North America inquiring about our vest, which is very exciting,” Williams says. “This outreach is telling us that there is a need for cooling strategies that are inclusive for all peoples, with or without disabilities. Our goal for the near future is to continue the cooling vest research project and to begin looking into more therapeutic applications. We feel that we can make a product that everyone can wear.”

PATENTS

Portable temperature controlled container

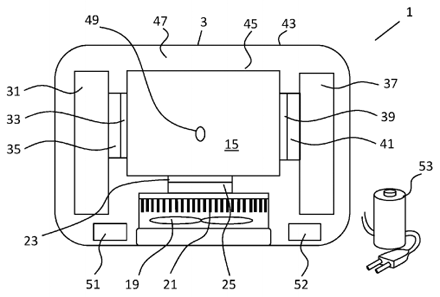

U.S. patent application 20160243000 (applicant Deltatrak Inc., Pleasanton, Calif.):

“This invention relates to a portable temperature controlled container comprising a body having a storage compartment, an opening to permit access to the storage compartment and an insulated lid. The container comprises a fan, a heat sink and a thermoelectric device, as well as a first phase change material and a thermoelectric device in thermal communication with both the first phase change material and the storage compartment. The thermoelectric device in thermal communication with both the first phase change material and the storage compartment is operable to remove energy in the form of heat from one of the storage compartment and the first phase change material and transfer that energy in the form of heat to the other of the storage compartment and the first phase change material. In this way, the device will require less power, be highly robust, will operate across a range of temperatures, and will be cost effective to manufacture.”

“This invention relates to a portable temperature controlled container comprising a body having a storage compartment, an opening to permit access to the storage compartment and an insulated lid. The container comprises a fan, a heat sink and a thermoelectric device, as well as a first phase change material and a thermoelectric device in thermal communication with both the first phase change material and the storage compartment. The thermoelectric device in thermal communication with both the first phase change material and the storage compartment is operable to remove energy in the form of heat from one of the storage compartment and the first phase change material and transfer that energy in the form of heat to the other of the storage compartment and the first phase change material. In this way, the device will require less power, be highly robust, will operate across a range of temperatures, and will be cost effective to manufacture.”

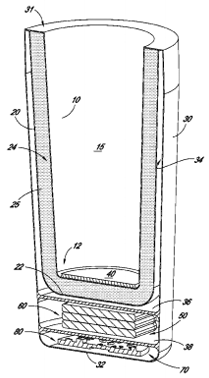

Heated or cooled portable drinkware

U.S. patent application 20160242598 (applicant Ember Technologies Inc., Westlake Village, Calif.):

U.S. patent application 20160242598 (applicant Ember Technologies Inc., Westlake Village, Calif.):

“An actively heated or cooled portable container is provided. The container has a portable body with a receiving portion defined by an inner wall that receives a liquid. A heating and cooling system housed in the portable body has a cooling element in thermal communication with at least a portion of the inner wall to remove heat from the liquid. The heating and cooling system also has a heating element in thermal communication with at least a portion of the inner wall, control circuitry to control the operation of the heating element and one or more power storage elements to provide electrical energy to the heating element and/or control circuitry. … The heating and cooling system comprises a cooling element comprising a phase change material disposed in a chamber that surrounds at least a portion of the inner sidewall so that the phase change material is in thermal communication with at least a portion of the inner sidewall of the portable body, the phase change material configured to transition from one phase to a second phase at a predetermined temperature.”

IN BRIEF

• SK Telecom‘s new fresh groceries logistics service features delivery trucks equipped with phase change material. The Smart FreshX system eliminates the need to burn fuel to run on-board chillers. The PCM is chilled at night, when electricity is cheaper, and keeps groceries cold during daytime deliveries. The South Korean company says the PCM technology increases cooling capacity by more than 50 percent and, in turn, reduces engine idle stress.

• The U.S. Environmental Protection Agency plans to publish proposed regulations under the revamped Toxic Substances Control Act by the end of this year.

• U.S. chemical producers must continue to prepare for fluctuations in feedstock pricing, writes Michael Hinton of Allegro Development: “Trying to predict energy market moves can be a mugs’ game, but effective commodity management systems can analyse a company’s trading history against the specific risk factors in its portfolio.”

• New from QY Research: “Global Micro-capsule Phase Change Composite Material Market Research Report 2016“

• Growing demand for greener products, cost-effective processing and cheaper feedstocks is driving an industry shift toward the production of biochemicals, BCC Research reports.

• The U.S. Department of Energy‘s Advanced Research Projects Agency-Energy has posted a request for information on lower-grade waste heat recovery systems. ARPA-E says it is particularly interested in solid-state recovery technology.

• High temperatures in the workplace are a major concern of trade union safety representatives, according to a survey conducted by the U.K.’s Trades Union Congress. The federation is calling for a maximum temperature of 30º Celsius in the workplace; 27º C for those doing strenuous work. [pdf]

• Croda CEO Steve Foots says the U.K.-based specialty chemicals company is on the lookout for acquisitions. Croda is focusing on “bolt-on deals providing access to new niches or established areas with fast-growing technologies,” the Financial Times reports. [subscription required]

• CoolComposites Inc. of Waltham, Mass., has won a $40,000 grant from the Massachusetts Clean Energy Center’s Catalyst program. The company is developing an inorganic phase change material to be used as a heat-absorbing additive for foam insulation. CoolComposites says the additive will improve the performance of building insulation by “up to 40 percent in warm environments, while increasing the cost to consumers by only 20 percent.”

• Alexium International has announced new sales contracts for its Alexicool phase change material in Europe, Asia and the Middle East. The unidentified new customers are in the “workwear, tenting and transportation” sectors.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Renewable and Sustainable Energy Reviews:• Preparation, heat transfer and flow properties of microencapsulated phase change materials for thermal energy storage

From Applied Energy:

• Characterization of granular phase change materials for thermal energy storage applications in fluidized beds

From Energy Conversion and Management:

• A thermal energy storage system provided with an adsorption module – Dynamic modeling and viability study

From Energy and Buildings:

• Thermal analysis of melting and freezing processes of phase change materials (PCMs) based on dynamic DSC test

• Experimental investigation of the performance of the novel HP-BIPV/T system for use in residential buildings

• Thermal conductivity enhancement of polyethylene glycol/expanded perlite with carbon layer for heat storage application

From Materials Letters:

• Assessing the potential for multi-functional “hybrid” porous Al-phase change material structures

From International Journal of Heat and Mass Transfer:

• Melting of nanoparticle-enhanced paraffin wax in a rectangular enclosure with partially active walls

• Thermal conductivity of cementitious composites containing microencapsulated phase change materials

From Energies:

• Heat Transfer and Energy Performance of a PVA Wall Tile Containing Macro-Encapsulated PCM

From International Journal of Structural and Civil Engineering Research:

• Study on the Phase Change Cement Based Material [pdf]

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 850 of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Keith Cardinal, director of package engineering, laundry and home care, Henkel Consumer Goods, Phoenix, Ariz.; Mickey Lazar, AquaPuraAfrica, Israel; and Laura Hutchison, designer at Ocean Rodeo Sports, Canada.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Keith Cardinal, director of package engineering, laundry and home care, Henkel Consumer Goods, Phoenix, Ariz.; Mickey Lazar, AquaPuraAfrica, Israel; and Laura Hutchison, designer at Ocean Rodeo Sports, Canada.

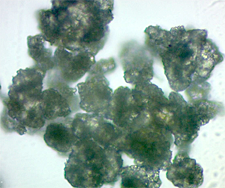

Vithursha Vijayarajah, who is studying textile processing at the University of Moratuwa in Sri Lanka, is seeking advice on a microencapsulation project. She attempted to use sodium alginate to encapsulate polyethylene glycol. As the photo here shows, her initial attempt failed. I’ve asked her to share her methodology and will post it on LinkedIn when it becomes available. Meantime, can anyone suggest a website she might find helpful in sorting this out?