The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

AUTOMOTIVE

Fraunhofer develops composite PCM to lower dashboard temperature

Researchers at the Fraunhofer Institute for Structural Durability and System Reliability LBF in Darmstadt, Germany, have developed a new phase change composite material designed to reduce the surface temperature of dashboards in vehicles.

Springer Professional of Germany has a good summary [translated from the German original]:

“The composite is suitable for a temperature phase transition and consists of a carrier material made of polyethylene, which can store energy. The filler graphite, on the other hand, ensures rapid heat dissipation. In a cyclic process of heating and cooling phases, the scientists were able to achieve a temperature reduction of 46 percent or 41 degrees Celsius compared to a conventional polypropylene-talc compound dashboard.”

Fraunhofer, of course, offers a more detailed look [also translated from German]:

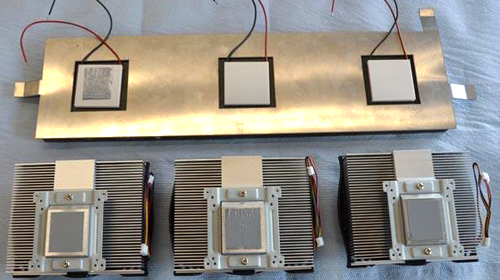

“To demonstrate the benefits of the new material, the scientists built this component into the dashboard of an electric vehicle to subsequently create a cycle of heating and cooling phases. The cooling was provided by Peltier elements. These electrothermal transducers are in turn cooled by external fans. The energy for Peltier elements and coolers comes from an additional 12 V battery powered by photovoltaic power.

“The energy released during the phase transition was used by the LBF researchers to switch on the Peltier elements only for a certain period of time. In this way, the fans do not have to constantly run at maximum power. By appropriate regulation, the cooling system is coupled to the temperature in the material. This should lead to a higher life expectancy of the electronic components. Thanks to a clever setting of the starting point of the working group, the Smart Cover Panel is controlled by the sunlight itself. This means that cooling only starts in hot summer days, and in winter the coveted warmth stays in the dashboard.”

PATENTS

Method for low-temperature microencapsulation of phase change material

U.S. patent application 20180223146 (inventors Mohammed Farid, Auckland, New Zealand, and Refat Al Shannaq, Shaheen Al-muhtaseb and Jamal Kurdi, Doha, Qatar):

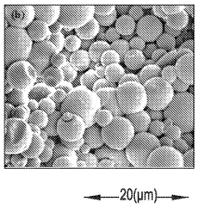

“The method for low temperature microencapsulation of phase change materials or other components includes the following steps: (a) preparing a phase change emulsion including droplets of at least one active phase-change material in water with a surfactant; (b) adding a monomer of at least one encapsulating agent; (c) introducing the phase change emulsion into a UV reactor while stirring the emulsion; and (d) initiating the photo polymerization of monomers using at least one UV lamp inside the UV reactor for photo polymerization until the phase change material is encapsulated within a polymeric shell to form microcapsules. The microcapsules obtained by this process may have a diameter between about 0.5 to about 2 μm. Other sizes can also be obtained by changing stirring speed of the emulsion.”

“The method for low temperature microencapsulation of phase change materials or other components includes the following steps: (a) preparing a phase change emulsion including droplets of at least one active phase-change material in water with a surfactant; (b) adding a monomer of at least one encapsulating agent; (c) introducing the phase change emulsion into a UV reactor while stirring the emulsion; and (d) initiating the photo polymerization of monomers using at least one UV lamp inside the UV reactor for photo polymerization until the phase change material is encapsulated within a polymeric shell to form microcapsules. The microcapsules obtained by this process may have a diameter between about 0.5 to about 2 μm. Other sizes can also be obtained by changing stirring speed of the emulsion.”

Evaporative cooling system and device

U.S. patent application 20180224212 (inventor George Michael Kaler Jr., Trophy Club, Texas):

“An evaporative cooling system includes an indirect cooling coil containing a cooling fluid to be circulated and a blower assembly configured to generate an inlet air stream through the indirect cooling coil. The cooling fluid in the indirect cooling coil is a slurry of water and phase change material.”

Thermal container insulated with phase change material

U.S. patent application 20180224178 (applicant Solee Science & Technology USA, Berkeley Heights, N.J.):

U.S. patent application 20180224178 (applicant Solee Science & Technology USA, Berkeley Heights, N.J.):

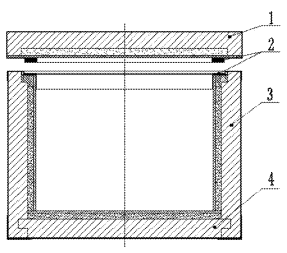

“A thermal container insulated with phase change material comprising a plurality of panels to form a body with a plurality of sides, a bottom and a lid, wherein each panel further comprises: a lining board, a phase change cold storage board, an insulation board; and a skin board. The phase change cold storage board further comprises an array of openings filled with solid-solid phase change material. The thermal container can maximize its storage capacity without compromising any volume for ice. It can maintain an accurate temperature range suitable for transportation. The container is reinforced at various locations to improve stability and structural integrity.”

Cooling system for vehicle interior surfaces

U.S. patent application 20180222517 (applicant Toyota Motor Engineering & Manufacturing North America Inc., Erlanger, Ky.):

“A vehicle component includes a first volume of phase change material and a second volume of phase change material spaced apart from the first volume of phase change material. The first volume of phase change material contains a greater mass of phase change material than the second volume of phase change material. The component also includes a thermally-conductive structure in direct contact with both the first volume of phase change material and the second volume of phase change material, so as to facilitate heat transfer between the first volume of phase change material and the second volume of phase change material.”

IN BRIEF

• Viking Cold Solutions founder and board chairman Paul Robbins, who retired as president at Caribbean Shipping Services in July, says he plans to resume a more active role in the day-to-day operations at Viking. The Houston company makes TES systems that pair phase change material with intelligent controls and remote energy-monitoring software to reduce commercial refrigeration costs.

• Chemical Week reports that shipping costs are on the rise for chemical companies as capacity tightens and truck traffic shifts to railroads.

• Inventure Renewables of Tuscaloosa, Ala., is partnering with Wilmar International and Desmet Ballestra Group on a new manufacturing plant in China’s Jiangsu province, the Birmingham Business Journal reports. Construction is expected to begin in 2019. The plant will use Inventure’s soap carbonate technology to convert low-value processing residues into uncontaminated free fatty acids.

• Maurizio Zaglio, right, international business development manager at Sunamp Ltd., was in Hangzhou, China, this week to present the company’s new products at the 2018 China Heat Pump Annual Conference.

• Maurizio Zaglio, right, international business development manager at Sunamp Ltd., was in Hangzhou, China, this week to present the company’s new products at the 2018 China Heat Pump Annual Conference.

• New from Research and Markets: “Phase Change Materials (PCMs) – A Global Market Overview“

• ARPA-E has issued a funding opportunity of up to $35 million for the High Intensity Thermal Exchange through Materials and Manufacturing Processes program, to develop new approaches and technologies for the design and manufacture of high-temperature, high-pressure, and highly compact heat exchangers.

• The American Chemistry Council confirmed this week that high-density polyethylene (HDPE) is on the list of U.S. petrochemicals and plastics targeted for $16 billion in retaliatory tariffs from China. “Prospects of trade war are eroding business confidence from the Tax Cuts and Jobs Act,” says the ACC’s Kevin Swift. The U.S. economy is expected to grow by 2.4 percent in 2019, Morningstar reports, but economists have cut the average forecast for 2020 from 2 percent to 1.8 percent.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

• Experimental investigation on thermal properties and thermal performance enhancement of octadecanol/expanded perlite form stable phase change materials for efficient thermal energy storage

• Effect of graphite mass concentrations in a mixture of graphite nanoparticles and paraffin wax as hybrid storage materials on performances of solar still

From Renewable and Sustainable Energy Reviews:

• A review on recent development for the design and packaging of hybrid photovoltaic/thermal (PV/T) solar systems

From Materials:

• Mechanical and Thermal Performance of Macro-Encapsulated Phase Change Materials for Pavement Application

From International Journal of Heat and Mass Transfer:

• Heat transfer behavior of elemental sulfur for low temperature thermal energy storage applications

• A novel method for determining the melting point, fusion latent heat, specific heat capacity and thermal conductivity of phase change materials

• Effect of microstructure on melting in metal-foam/paraffin composite phase change materials

From Chemical Engineering Journal:

• Flexible phase change materials for thermal storage and temperature control

From Construction and Building Materials:

• Experimental investigation of thermal and mechanical properties of magnesium oxychloride cement with form-stable phase change material

From Solar Energy:

• New insights into the corrosion mechanism between molten nitrate salts and ceramic materials for packed bed thermocline systems: A case study for steel slag and solar salt

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,300 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,300 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Selma Yilmaz Baylani, R&D and quality control chief at Beyaz Kağıt, Adana, Turkey; Thierry Leclercq, export sales manager at FAFCO SA, Chevigny-Saint-Sauveur, France; and John Lawson, cold chain laboratory manager at EFP Corp., La Vergne, Tenn.