The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

COLD STORAGE

Bermuda food distributor uses PCM thermal storage to cut refrigeration costs

Thermal cells made by Viking Cold Solutions of Houston, Texas, have helped a food distributor in Bermuda reduce refrigeration costs by 40 percent.

The thermal cells were installed in the ceiling of Butterfield and Vallis‘ 10,000-square-foot warehouse freezer in 2015. The cells consist of a salt hydrate solution contained in conductive thermal plastic tubes. The phase change material solidifies when the chillers are running. The PCM absorbs heat as it melts, allowing the chillers to run less frequently and still keep the warehouse within a few degrees of -18º Celsius.

The system is among 20 built and installed by Viking in cold storage warehouses in Puerto Rico, Bermuda, St. Thomas, California, New Mexico and Texas. Collin Coker, Viking’s vice president for sales and marketing, said his company is working on pilot grocery store installations in Texas and California.

Spencer Butterfield, chief operating officer at Butterfield and Vallis, told Bermuda’s Royal Gazette newspaper that a 2013 tax break on the importation of energy-saving technology helped make the system economically feasible. He estimated that the system will pay for itself in four years.

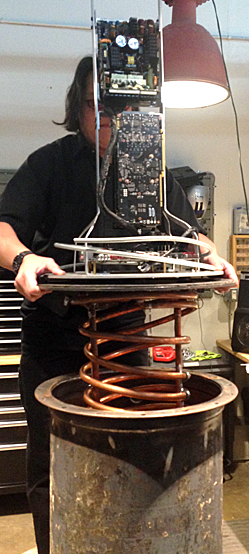

The design of Viking’s thermal cells continues to evolve. Above: The system installed at New Mexico Foods in 2015 consists of film pouches suspended in steel racks. Below: The company’s newest design consists of blow-molded HDPE bottles mounted on steel tubing.

PATENTS

Removable adhesion material with PCM

U.S. patent application 20160058674 (assignee RWTH Aachen University, Germany):

“The present invention relates in a first aspect to an adhesion material for use in an individual containing encapsulated phase-change material. In particular, the adhesion material is for cosmetical or medicinal use in the body of an individual. The adhesion material contains encapsulated phase-change material having preferably a phase transition temperature above 40º C., like above 55º C. The adhesion material is particularly useful for adhering elements, like dental restorations, e.g. crowns or bridge, or brackets on elements in the body of an individual, like teeth or implants. That is, the adhesion material is particularly useful for adhering material in dental applications.”

HVAC

Meet DareHenry, a high-performance computer designed to heat homes, businesses

Meet DareHenry, a high-performance computer designed to heat homes, businesses

New York inventor Lawrence Orsini began work last year on Project Exergy, a plan to develop high-performance computers that capture, store and distribute the heat they generate. The computers would be deployed in homes and businesses instead of server farms, with the excess thermal energy used to heat those locations and reduce energy costs.

Orsini is now working on stage 2 prototypes dubbed “DareHenry,” using fatty acid/fatty ester phase change material as a thermal storage medium.

He continues to pursue funding for the project, which raised more than $18,000 on IndieGoGo last year. Project Exergy made it to the final four for Department of Energy R&D funding as part of a team that included NREL and is still in the hunt for ARPA-E funding, Orsini said in an e-mail interview.

At right is one of several DareHenry prototypes with a 50-gallon phase change thermal storage tank.

IN BRIEF

• More than 50 national labs in the United States opened their doors this week to about 5,000 elementary, middle and high school students. It’s part of President Obama‘s effort to spark interest among young people in science, technology, engineering and math.

• The agenda has been set for this year’s Global Chemical Regulations Conference in Washington, D.C., March 22-24. Among the topics: Toxic Substances Control Act reform and Global Harmonized Standards enforcement.

• Forty-five companies, universities and research organizations backed by ARPA-E have secured more than $1.25 billion in private-sector follow-on funding. The Massachusetts Institute of Technology, which is working on metallic composite phase change materials for high-temperature thermal energy storage, is among those receiving private-sector money.

• In a new technical paper on puretemp.com, Dr. Aymara Albury of Entropy Solutions explains how thermal conductivity of phase change materials is measured and why it matters.

• In an interview with CleanTechnica, Ice Energy CEO Mike Hopkins shares new details on the Ice Bear 20, a thermal energy storage system aimed at the residential market. The unit is designed to cool homes up to 3,500 square feet, “is as easy to install as the compressor unit of a traditional air conditioner” and will cost the same as a conventional air conditioning system.

• New from Zion Research: “Microencapsulation Market for Pharmaceuticals, Household Products, Agrochemicals, Food Additives and Other Applications: Global Industry Perspective, Comprehensive Analysis and Forecast, 2014 – 2020.” The report projects global demand for microencapsulation will reach $9.25 billion in 2020, a compound annual growth rate of 9.5 percent.

• New from Future Market Insights: “Temperature Controlled Packaging Solutions Market: Global Industry Analysis and Opportunity Assessment 2015-2025”

• The Welsh government has award Dulas $80,000 to support development of the company’s solar direct-drive vaccine refrigerators. Phase change material that freezes and thaws at 5º C helps keep vaccines at the proper temperature without power from the grid.

• Compression shirts and briefs infused with Outlast phase change technology helped reduce chafing and rashes in tests conducted with law enforcement professionals. The apparel, made by 91 Degrees F, displayed “superior sweat management, reduced chafing, and a uniform shirt that maintained its crisp appearance throughout the test.”

• Sonoco ThermoSafe‘s new pallet selector tool allows customers to quickly identify the product best suited to their needs.

• Correction: An item in last week’s newsletter incorrectly identified the location of the Marine Corps Logistics Base-Albany. It is in Georgia.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Sustainable Energy Technologies and Assessments:• Economic optimization of PCM and insulation layer thickness in residential buildings

From International Journal of Heat and Mass Transfer:

• Investigation of nanoparticle agglomeration on the effective thermal conductivity of a composite material

From Energy and Buildings:

• Nanoencapsulation of butyl palmitate in polystyrene-co-methyl methacrylate shell for thermal energy storage application

• Energy saving potential of a ventilation system with a latent heat thermal energy storage unit under different climatic conditions

• Numerical Techniques to Model Conduction Dominant Phase Change Systems: A CFD Approach and Validation with DSC Curve

From Journal of Physical Chemistry:

• Computational Analysis of Sugar Alcohols as Phase-Change Material: Insight into Molecular Mechanism of Thermal Energy Storage

From Heat and Mass Transfer:

• Experimental investigation on the thermal performance of heat storage walls coupled with active solar systems

From Industrial & Engineering Chemistry Research:

• Preparation and characterization of thermoregulated rigid polyurethane foams containing nanoencapsulated phase change materials

From Composites Part B: Engineering:

• Fatigue behavior enhancement of short fiber glass reinforced polyamide by adding phase change materials

From Applied Energy:

• A novel phase-change cement composite for thermal energy storage: Fabrication, thermal and mechanical properties

From Energy:

• Investigation of the effects of thermal, oxidative and irradiation treatments on the behaviour of poly-ethylene glycol as a phase change material in thermal energy storage systems

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 600 of your peers have joined a new LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Niall Lehane, general manager at ThermoSafe Brands Europe; Dean Tonna, technical consultant at Monodraught Ltd.; and Gonzalo Diarce Belloso, researcher at the University of New South Wales.

YOUR TURN

Wanted: News tips about PCMs and thermal energy storage

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? We would love to hear from you. Please contact Ben Welter of Entropy Solutions at bwelter@puretemp.com.