The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

COMPANY NEWS

Vertellus doubles alkane production capacity at Michigan plant

Vertellus, a manufacturer of specialty chemicals, has doubled alkane production capacity at its Zeeland, Mich., hydrogenation plant. The company expects alkanes to be one of several innovative chemistries supplying a growing global market for phase change material.

“North America’s competitive feedstock costs resulting from low natural gas prices are helping drive Vertellus’ alkane production efficiencies,” the company said in a news release. “The company initiated the Zeeland upgrades in 2014, the same year it commercialized hexadecane (A16T). With added alkane production capacity in place, Vertellus will develop eicosane (A20T) in its 2015 pipeline. Octadecane (A18T) represents the company’s largest category of alkane production due to its ability to absorb and release heat close to the human body temperature.”

Cryopak opens manufacturing plant in California

Cryopak, a maker of insulated shipping containers, gel packs and phase change materials, has opened a new manufacturing facility in Poway, Calif. The company, a subsidiary of TCP Reliable, is based in Edison, N.J.

Cryopak, a maker of insulated shipping containers, gel packs and phase change materials, has opened a new manufacturing facility in Poway, Calif. The company, a subsidiary of TCP Reliable, is based in Edison, N.J.

“The addition of local manufacturing will allow us to provide better support to our customers on the West Coast and the important Southern California market,” said Maurice Barakat, TCP’s president and CEO.

REFRIGERATION

PCM refrigeration conference set for May 2016 in Germany

An international conference on phase change materials and slurries for refrigeration and air conditioning is set for May 18-20, 2016, in Karlsruhe, Germany.

PCM 2016, sponsored by the International Institute of Refrigeration, will bring together scientists, researchers and industry leaders to discuss the latest developments in the field. Topics will include:

• Thermophysical properties of PCMs and slurries

• Transport phenomena of PCMs and slurries: mass, momentum and heat transfer

• Time-dependent behavior of PCMs and slurries

• Direct contact heat exchange

The conference will be conducted in English. Abstracts are due by Nov. 1; final papers are due by March 15.

PATENT APPLICATIONS

Polyurethane gel particles for use in flexible foams

U.S. patent application 20150197610 (applicant Peterson Chemical Technology Inc., Fort Smith, Ark.):

“Combinations of open cell flexible foams with polyurethane gel particles, and methods of making the combinations are described using a variety of procedures. The open cell flexible foam may partially or wholly comprise polyurethane foam and latex foam. …

[Claim 2] The composition of claim 1 where the polyurethane gel particles contain at least one phase change material with a solid/liquid phase transition temperature range of from about −10° F. to about 220° F. (about −23° C. to about 104° C.). “

Manufacturing a composite PCM for clothing

U.S. patent application 20150197678 (assignee Honeywell International Inc.):

“Composite phase change materials, methods for manufacturing composite phase change materials, and articles of clothing including composite phase change materials for temperature regulation are provided. In one example, a composite phase change material includes a cross-linked polyethylene glycol matrix and a phase change material filler. Each of the cross-linked polyethylene glycol matrix and the phase change material filler has a phase change temperature of from about 10 to about 60° C. Further, the composite phase change material has a latent heat of enthalpy greater than about 50 kJ/kg.”

Phase change materials for refrigeration and ice making

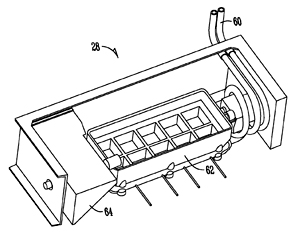

U.S. patent application 20150198359 (assignee Whirlpool Corp.):

“A bottom mount refrigerator is provided including a thermal battery or phase change material positioned within the refrigerator or freezer in order to increase energy efficiency and compartment sizes of the refrigerator. The thermal battery can be used with an ice maker to aid in removing heat from the water in the ice maker to produce ice. Furthermore, the phase change material or thermal battery may be used with a thermoelectric cooler to aid in ice production.

“A bottom mount refrigerator is provided including a thermal battery or phase change material positioned within the refrigerator or freezer in order to increase energy efficiency and compartment sizes of the refrigerator. The thermal battery can be used with an ice maker to aid in removing heat from the water in the ice maker to produce ice. Furthermore, the phase change material or thermal battery may be used with a thermoelectric cooler to aid in ice production.

“The phase change material may be tuned to various temperatures according to the desired use of the phase change material, as well as the location of the thermal battery or phase change material. Other embodiments include positioning the phase change material in the liner of the compartments or in thermal storage units in order to further increase the energy efficiency of the refrigerator.”

Phase change compressor cover

U.S. patent application 20150192334 (applicant Trane International Inc.): “A phase change compressor cover may include a first layer configured to provide sound attenuation from undesirable noise produced as a result of operating a compressor and/or thermal isolation of the compressor and a second layer comprising a cavity filled with a phase change material that is configured to absorb heat discharged as a result of operating the compressor and subsequently discharge the absorbed heat onto the compressor in response to discontinuing operation of the compressor to keep the compressor warm and prevent refrigerant migration to the compressor.”

Composite catalyst/PCM for use in catalytic reactions

U.S. patent application 20150190796 (assignee French Atomic Energy and Alternative Energies Commission): “Material with hybrid particles each consisting of a particle of a phase-change material (PCM) interfaced with a catalytic material in solid form, the size of the hybrid particles being between 0.1 mm and 10 mm, preferably between 1 mm and 5 mm.”

JOB OPENING

Croda seeks PCM market applications specialist

Croda’s Industrial Chemicals Division is looking for a market applications specialist with experience in phase change materials.

The applications specialist will help develop new products based on customer needs, develop new test methods and work on encapsulation projects. A degree in chemistry or chemical engineering, or equivalent experience, is required. Croda’s PCM research and development team is located in Gouda, the Netherlands.

THERMAL STORAGE

Promethean’s rapid milk chiller is finding niche in India

Greentech Media gets an update on Promethean Power Systems‘ rapid milk chiller from Sorin Grama, the company’s chief technology officer.

Using a thermal battery filled with phase change material, the chiller needs only intermittent electricity to quickly chill raw milk to a temperature that arrests bacterial growth. It’s designed for use in rural parts of developing countries, where milk-collection sites don’t have access to reliable electricity.

Using a thermal battery filled with phase change material, the chiller needs only intermittent electricity to quickly chill raw milk to a temperature that arrests bacterial growth. It’s designed for use in rural parts of developing countries, where milk-collection sites don’t have access to reliable electricity.

The company introduced the device in India and has said it plans to expand distribution to Bangladesh, Pakistan and Sri Lanka this year. Each unit costs around $8,000 to $10,000.

“Our systems are just a bit more expensive to buy than a regular diesel generator system, but the savings in operating costs make up the difference in less than one year. Our operating costs can be half of the operating cost of an equivalent chiller running with partial diesel power,” said Grama, right.

About 150 units have been sold so far, he said. In April, co-founder Sam White said Promethean hopes to have 500 units in the field by the end of the year.

Solar 2015 includes session on feasibility of seasonal ice storage

Richard D. Wilk, professor of mechanical engineering at Union College, will present research on the feasibility of seasonal ice thermal energy storage at the Solar 2015 conference at Penn State later this month. Other session topics include “The Great Solar Thermal Debate,” “Research Advances in Solar Thermal,” “Solar Thermal’s Future: The Big Picture” and “High Performance Buildings.”

Richard D. Wilk, professor of mechanical engineering at Union College, will present research on the feasibility of seasonal ice thermal energy storage at the Solar 2015 conference at Penn State later this month. Other session topics include “The Great Solar Thermal Debate,” “Research Advances in Solar Thermal,” “Solar Thermal’s Future: The Big Picture” and “High Performance Buildings.”

Here’s a description of the July 29 poster session on seasonal ice storage:

“The system consists of a large insulated volume capable of storing large amounts of snow and ice collected in the winter, and storing it for weeks to months to produce chilled water for cooling buildings in hot weather. This project involved developing a transient heat transfer model to predict the time-dependent temperature of a snow/ice bed in a well-insulated compartment subjected to heat gain from the environment and simulated building cooling system return water. The model was used to study the effects of design parameters, like insulation type and thickness as well as the return water flow rate on the melt time.”

RENEWABLE ENERGY

On blustery day, wind power generates 140% of Denmark’s electrical demand

At one point on an unusually windy day last week, Danish wind farms were producing 140 percent of the country’s electricity needs, London’s Guardian newspaper reports.

“Interconnectors allowed 80% of the power surplus to be shared equally between Germany and Norway, which can store it in hydropower systems for use later,” the Guardian reported. “Sweden took the remaining fifth of excess power. …

“A surge in windfarm installations means Denmark could be producing half of its electricity from renewable sources well before a target date of 2020, according to Kees van der Leun, the chief commercial officer of the Ecofys energy consultancy.”

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Energy:• Peak load shifting with energy storage and price-based control system

From Renewable Energy:

• Thermal energy storage in building integrated thermal systems: A review. Part 2. Integration as passive system

From SAE International:

• How Ice Based Thermal Energy Storage Can Help Cut Electricity and Fuel Costs of Indian Railways

From Solar Energy Materials and Solar Cells:

• Thermal properties of shape-stabilized phase change materials using fatty acid ester and exfoliated graphite nanoplatelets for saving energy in buildings

From Procedia Engineering:

• Experimental Thermal Performance Analysis of Building Components Containing Phase Change Material (PCM)

From ASME:

• Industrial Surplus Heat Storage in Smart Cities

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 240 of your colleagues have joined a new LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Benjamin Redlingshöfer, managing director at smartpolymer GmbH, Germany. He writes:

At smartpolymer one of our segments deals with almost all kinds of PCM applications. Starting from PCM-Granules on a polymer base, PCM-Fibres e.g. for comfort effect in fabrics up to PCM-Slurries which offer a very interesting field of operation especially in HVAC. Let’s get into touch and start interesting discussions!

YOUR TURN

Got a question about PCMs or TES? Ask our experts

Two Entropy Solutions advisors, Dr. Mohammed Farid of the University of Auckland and Lucas B. Hyman of Goss Engineering, are ready to answer your questions about phase change material and thermal energy storage. We’ll select the best questions sent to inquiries@puretemp.com and post the answers here each Friday.