The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

ENERGY STORAGE

Inside Federal Center South, an ASHRAE award-winning project

A U.S. Army Corps of Engineers office building in Seattle was one of nine projects recognized for innovative design with an ASHRAE Technology Award in December. Federal Center South received first place in the new commercial buildings category.

A U.S. Army Corps of Engineers office building in Seattle was one of nine projects recognized for innovative design with an ASHRAE Technology Award in December. Federal Center South received first place in the new commercial buildings category.

The Seattle Daily Journal of Commerce takes a closer look at the project, including the months of tweaking needed to reach the energy-use guarantees made by the general contractor, Sellen Construction.

“This is not your father’s 1960s pickup truck,” said Tom Boysen, senior project manager. “This thing has at least four gears of cooling and two gears of heating.”

The complex system includes heat-recovery chillers that extract heat from a thermal storage tank to warm the building in the morning, when demand is high. The rooftop tank is filled with 2-foot-long panels containing phase change material that freezes and thaws at 55 degrees, serving as a battery for storing heat.

BUILDING/CONSTRUCTION

PCM vs. thermal mass: A design firm’s take

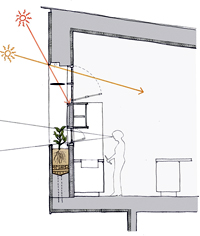

Phase change materials and thermal mass can be used to regulate temperatures in homes and offices. Australian design firm EME offers a brief look at the two approaches, outlining the advantages of each.

Phase change materials and thermal mass can be used to regulate temperatures in homes and offices. Australian design firm EME offers a brief look at the two approaches, outlining the advantages of each.

Any material that is heavy and dense – brick, stone, concrete, earth, sand and even water – qualifies as thermal mass. Heavy, dense walls can slow the rate at which the sun’s heat enters a space and the rate at which a space loses heat at night. But thermal mass can be, well, massive.

“One advantage of phase change,” EME writes, “is that it is lighter in weight and therefore can be integrated into a retrofit situation without upgrading the structure and multi-storey buildings. Unlike thermal mass construction, phase change does not have the poetry and material sensibility that thermal mass offers. Phase change is generally concealed within a wall.”

NEW PRODUCTS

Protective suit for offshore work features PCM liner

Gas and oil personnel don protective suits for helicopter transfer to and from offshore platforms. Viking Life-Saving Equipment’s new PS5040 suit is designed for harsh weather and icy waters. The snug-fitting suit features a gas-inflated buoyancy system, integrated spray hood, easy-to-use plastic zippers and a thermal liner that contains phase change materials that absorb the excess body heat and returns it when needed.

“When it comes to passenger suits for helicopter transfer, there are a number of commonly used materials and features that are well-suited to the task,” said Jens Peter Kruse, the Danish company’s vice president for personal protective equipment. “We’ve taken this into account with our new suit, and we’ve made a tremendous number of comfort and safety improvements, too.”

RESEARCH ROUNDUP

JOB OPENING

Operations Manager at Entropy Solutions’ R&D lab in Alabama

Entropy Solutions, maker of PureTemp, the world’s first 100 percent renewable phase change material, is accepting applications for the position of Operations Manager at the company’s research and development lab in Tuscaloosa, Ala. Working closely with our team of top-notch scientists, the Operations Manager will help direct a wide range of project- and infrastructure-related initiatives.