The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

MANUFACTURING

North American PCM group to hold inaugural meeting Oct. 5

In December 2016, representatives of several U.S.-based PCM makers attending a thermal mass workshop in Florida agreed to work together to form a PCM manufacturers association, with a goal of promoting the development and use of phase change material in North America.

Since then, many of the details necessary to establish this organization have been worked out: Bylaws have been drafted, a mission statement written and a list of potential members compiled.

The group has now set a date for its inaugural meeting. More than three dozen people representing PCM manufacturers, research organizations and government agencies have been invited to the Fraunhofer Center for Sustainable Energy Systems in Boston on Oct. 5 to celebrate the creation of the Phase Change Materials Industry Association.

The agenda includes presentation of the mission statement and bylaws, election of officers, and discussion of membership fees and next steps. For more information about the new organization, please contact Jan Kosny, director of Building Enclosures and Materials at Fraunhofer CSE.

TRANSPORTATION

Paraffin-enhanced concrete shows promise in melting ice, snow

Dr. Yaghoob Farnam has spent four years combining concrete and phase change material in various ways in a quest to develop a durable paving material that can melt ice and snow.

Farnam, an assistant professor in Drexel University’s College of Engineering, has previously measured the effectiveness of paraffin oil and methyl laurate, materials that have relatively high heat storage capacity (about 130 to 170 joules per gram) and a suitable phase transformation temperature (about 2 to 3 degrees Celsius). Both showed promise when contained in plastic tubes embedded in concrete. But the paraffin oil proved to be far more effective than methyl laurate in concrete made of lightweight aggregate infused with the PCMs. Chemical reactions between the methyl laurate and materials in the cement rendered that PCM ineffective and also appeared to cause cracks in the concrete.

In his latest paper, published in Cement and Concrete Composites, Farnam’s research team focused on paraffin oil. The team used concrete slabs to compare two methods of deploying the PCM. Steel pipes filled with paraffin and sealed with PVC caps were embedded in one slab. A second slab was made of porous lightweight aggregate infused with paraffin. A third slab, containing no paraffin, served as a reference point. Each slab was sealed in an insulated container and then covered with about 5 inches of shaved ice.DrexelNow describes what happened in two tests:

“With temperatures inside the boxes held between 35-44 degrees Fahrenheit, both of the paraffin-treated slabs were able to completely melt the snow within the first 25 hours of testing, while the snow on the reference sample remained frozen. The slab with the paraffin-filled tubes melted the snow slightly faster than the one composed of paraffin-treated aggregate. Farnam suggests that this is because the paraffin inside the tubes is able to solidify more quickly — thus releasing its energy — because of the regular diameter of the pipes. While the diameter of the pores of the aggregate vary in size.

“But in the group’s second experiment, in which the ambient air temperature in the box was lowered to freezing before the snow was added, the paraffin-treated aggregate was more effective than the embedded pipes. This is because the capillary pore pressure delayed the freezing of the paraffin, thus allowing it to release its heat energy over a longer period of time.”

The research is of particular importance to the airline industry, which has a keen interest in finding cost-effective and environmentally friendly ways to clear runways of ice and snow. The Federal Aviation Administration has supported Farnam’s work with nearly $500,000 in grants through its PEGASAS program.

Farnam says additional research is needed to better understand how the addition of PCM affects pavement durability, skid resistance and long-term stability.

PATENTS

Air-conditioning system for a machine

U.S. patent application 20170267066 (applicant Caterpillar Inc., Peoria, Ill.):

“An air-conditioning system including a primary circuit and a secondary circuit is provided. The primary circuit includes a flow of refrigerant, an evaporator and a chiller configured to exchange heat between a coolant and the refrigerant. The secondary circuit includes a heat exchanger in fluid communication with the chiller to receive the coolant. The heat exchanger includes a phase change material in heat exchange relationship with the coolant, such that the coolant exchanges heat with the phase change material to store thermal energy in the phase change material. The air-conditioning system is implemented in a machine in which during an idle-off state, the stored energy in the heat exchanger is discharged to provide an air-conditioning effect.”

Breathable product for protective mass transportation and cold chain

U.S. patent application 20170266609 (applicant E.I. DuPont De Nemours and Co., Wilmington, Del.):

“The present invention concerns a breathable product for protective mass transportation and cold chain applications, in particular a reflective sheet for covering temperature sensitive products the reflective sheet having at least a first layer made of a highly reflective moisture vapor permeable substrate having an outer side and an inner side, wherein said inner side comprises in addition at least a metal layer deposited by a PVD process to provide a thermal insulation through high reflection low convection while providing controlled moisture vapor permeability. … The honeycomb structural element provides some additional thermal insulation because the spaces inside are filled with air, but these spaces may also be filled with a phase change material such as a wax, which will absorb and liberate additional heat during melting and freezing when the temperature distribution within the layers is favorable and the presence of the phase change material is not detrimental to the protected goods.”

IN BRIEF

• Alas, no chemistry prize was handed out at the Ig Noble awards ceremony at Harvard University last week. The annual “Igs,” first awarded in 1991, are designed to recognize research efforts that “first make people laugh, and then make them think.” This year’s physics prize was awarded to Marc-Antoine Fardin, a physicist at Paris Diderot University, for using fluid dynamics to probe the question “Can a Cat Be Both a Solid and a Liquid?” His conclusion: Yes.

• The World Wildlife Fund has partnered with the American Chemistry Council, Recycling Partnership, Ocean Conservancy, Target, Nestle and other organizations to find opportunity and economic value in expanding the availability and use of secondary material. Members of the initiative, known as the Cascading Materials Vision, introduced the concept of “cascading value” in two sessions at this week’s Verge Conference in Santa Clara, Calif.

• New from COMSOL: Modeling a novel PCM-enhanced plaster with numerical simulation

• New from QY Research: “2017 Market Research Report on Global Energy Storage Devices Industry”

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Soft Matter:• Feasibility of Using Microencapsulated Phase Change Materials as Filler for Improving Low Temperature Performance of Rubber Sealing Materials

From Journal of Cleaner Production:

• Investigation of pork fat as potential novel phase change material for passive cooling applications in photovoltaics

From Solar Energy Materials and Solar Cells]:

• Superwetting polypropylene aerogel supported form-stable phase change materials with extremely high organics loading and enhanced thermal conductivity

• Polyethylene glycol-enwrapped silicon carbide nanowires network/expanded vermiculite composite phase change materials: Form-stabilization, thermal energy storage behavior and thermal conductivity enhancement

From Applied Thermal Engineering:

• Solar desalination using solar still enhanced by external solar collector and PCM

From Energy Procedia:

• Using Thermal Inertia of Buildings with Phase Change Material for Demand Response

• Preparation of microencapsulated phase change materials (MEPCM) for thermal energy storage

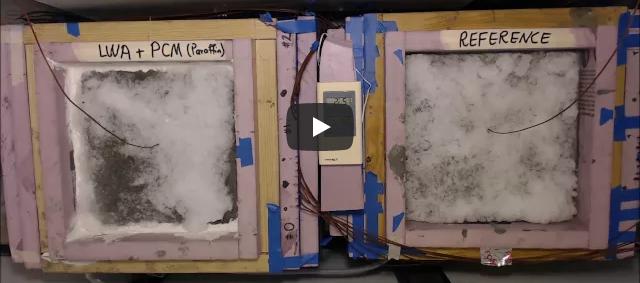

• New experimental technique to investigate the thermal behavior of PCM/doped concrete for enhancing thermal/energy storage capability of building envelope

• Levelized cost of energy (lcoe) analysis of a low temperature PCM thermal storage combined with a micro-CHP in an apartment block

• Numerical simulation of a complete charging-discharging phase of a shell and tube thermal energy storage with phase change material

• Numerical simulation of a finned-tube LHTES system: influence of the mushy zone constant on the phase change behaviour

From International Journal of Heat and Mass Transfer:

• Study of thermal conductive enhancement mechanism and selection criteria of carbon-additive for composite phase change materials

From Energy Conversion and Management:

• Heat transfer enhancement of phase change materials by fins under simultaneous charging and discharging

From Energy and Buildings:

• Experimental study on using PCMs of different melting temperatures in one cooling vest to reduce its weight and improve comfort

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,10o people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members include Heidi Crandall, technical expert in refrigerant systems at Gentherm Inc., Northville, Mich.; Lluis Gómez Berenguer, founding partner at CloudPangea, Murcia, Spain; and Sujay Venkatachalam, chief operations officer, Global National Australia, Melbourne, Australia.

You are invited to join the group and connect with PCM and TES experts from around the world. New members include Heidi Crandall, technical expert in refrigerant systems at Gentherm Inc., Northville, Mich.; Lluis Gómez Berenguer, founding partner at CloudPangea, Murcia, Spain; and Sujay Venkatachalam, chief operations officer, Global National Australia, Melbourne, Australia.