The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

MANUFACTURING

PCM makers to discuss formation of North American manufacturers group

Makers of phase change materials will gather in Florida Dec. 4 to discuss the possibility of forming a North American PCM manufacturers association.

The discussion, led by Dr. Jan Kosny of the Fraunhofer Center for Sustainable Energy Systems, will take place at the end of an all-day workshop on thermal mass. The workshop is part of the Buildings XIII Conference at the Sheraton Sand Key Resort in Clearwater Beach, Fla.

PCMs have been a focus of the workshop since it was first held in 2001.

“Most of U.S. PCM manufacturers and companies producing PCM products for buildings participated in this workshop at least once,” said Kosny, who leads building enclosure research at Fraunhofer CSE. “At some point we had a discussion about a creation of the PCM manufacturers’ association. Since this topic has been hanging in the air for at least a decade, this year I decided that it will be good to learn how much support there will be for this idea and who will be supporting this initiative. As usual, I am sending invitations to all major PCM companies in the U.S. and major U.S. building material manufacturers.”

What are the greatest challenges facing North America’s PCM industry?

“The answer is application specific,” Kosny explained. “PCM products are used by many different industries. However, the major problems which I would identify are: (i) high cost); (ii) flammability; (iii) long-term performance; (iv) durable packaging; (v) lack of material standards; (vi) lack of uniform performance criteria for PCM products used by specific industries, etc.”

Entropy Solutions, Phase Change Energy Solutions, Applied Innovation Group and Cool Composites are among the companies planning to attend the workshop. Representatives of the U.S. General Services Administration, Oak Ridge National Laboratory, Lodz University of Technology, Colorado School of Mines, Microtek Laboratories, Fraunhofer CSE and the Department of Energy‘s Building Technologies Office will give presentations on microencapsulation, macroencapsulation, performance modeling, testing methods, durability issues and more.

“The attendees of this conference include the ‘PCM who’s who’ in academics, government and industry,” said Dr. William R. Sutterlin, Entropy Solutions’ chief science officer. “It will help shape the future of PCMs in buildings, modeling of PCM behavior, new developments and PCM testing methods.”

The registration fee for the full conference, Dec. 4-8, is $695. One-day attendance is $295 and the cost for the workshop is $100. Registration deadline is Nov. 23.

PATENTS

Intermittent power grid ready cooler

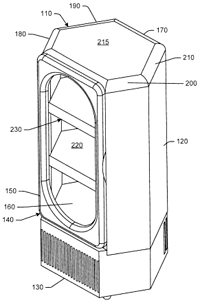

U.S. patent application 20160313046 (applicant Coca-Cola Co., Atlanta, Ga.):

“A method of operating a cooler with intermittent power, comprising: positioning a number of shelf assemblies within the cooler; wherein the shelf assemblies comprises a phase change material and an evaporator therein; circulating a refrigerant about the phase change material when the power is on; freezing the phase change material; and maintaining the cooler in a chilled condition for an extended period of time when the power is off by melting the phase change material.”

Container with PCM and graphite powder mix

U.S. patent application 20160309932 (applicant Fraunhofer Society for the Promotion of Applied Research):

“A container may be provided, in particular a beverage container, comprising an inner container wall and an outer container wall, an intermediate space lying between the container walls, wherein the intermediate space is filled with a mixture that contains phase-change material and graphite powder, wherein the graphite powder is introduced into the phase-change material in such a way that the mixture has a pulpy consistency at a temperature at which the phase-change material is liquid. A method may be provided for producing a container that includes the following steps: A) providing an inner container wall and an outer container wall; B) applying a mixture of graphite powder and phase-change material to the inside of the outer container wall and/or the outside of the inner container wall; C) joining the outer container wall and the inner container wall.”

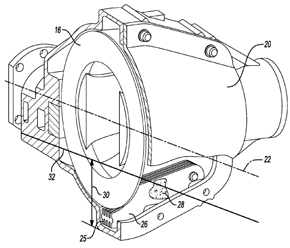

Axle heat absorber with PCM

U.S. patent application 20160312878 (applicant Ford Global Technologies, Dearborn, Mich.):

U.S. patent application 20160312878 (applicant Ford Global Technologies, Dearborn, Mich.):

“An axle includes a differential, a cover, and a heat absorber. The differential has a ring gear disposed within a housing. The ring gear is configured to pump a lubricating fluid. The cover is attached to the housing. The heat absorber is attached to the cover within a pump path of the ring gear. The heat absorber has a phase-change material disposed within the heat absorber configured to absorb heat from the lubricating fluid. A method to control fluid temperature in a vehicle axle is also included.”

IN BRIEF

• A handful sessions scheduled for the 2017 Energy Storage World Forum and Residential Energy Storage Forum are related to thermal energy storage: “Niche Energy Storage Technologies,” led by Pierre-Guy Therond, director of new technologies at EDF Energies Nouvelles of France; “Synergistic Combinations of Energy Storage Technologies,” led by John Hatton, chief commercial officer at Alpheon Energy, United Kingdom; and “Integrating Storage to Improve Renewable Generation Capacity Factor,” led by Martin Wilcox, senior consultant at Mott MacDonald, United Kingdom. The conferences will be held May 8-12 in Berlin.

• Dr. Dileep Singh of Argonne National Laboratory has been named a fellow of ASM International for his work on concentrating solar power and other energy innovations. Singh and his team developed a latent heat-based thermal energy storage system that enhances the performance of phase change material using high-conductivity graphite foam.

• Dulas Ltd. has added a 52.5-liter model to its line of solar-powered refrigerators. The VC50SDD is powered by the British company’s Solar Direct Drive technology and uses paraffin-based phase change material to keep vaccines and other payloads at temperatures ranging from 5°C to 43°C. With an optional “integrated solar socket,” the refrigerator can also be used to charge cellphones or temperature-monitoring equipment. The World Health Organization earlier this month approved the refrigerator for purchase by UNICEF and other U.N. agencies.

• Dulas Ltd. has added a 52.5-liter model to its line of solar-powered refrigerators. The VC50SDD is powered by the British company’s Solar Direct Drive technology and uses paraffin-based phase change material to keep vaccines and other payloads at temperatures ranging from 5°C to 43°C. With an optional “integrated solar socket,” the refrigerator can also be used to charge cellphones or temperature-monitoring equipment. The World Health Organization earlier this month approved the refrigerator for purchase by UNICEF and other U.N. agencies.

• Two new reports from QYResearch: “Global Thermal Energy Storage (TES) Market Professional Survey Report 2016” and “Europe Advanced Phase Change Materials (PCM) Market Report 2016.”

• MatériO has opened its new materials library in Shanghai, with more than 1,000 materials on display. MatériO, based in France, lists more than 7,400 “cutting edge” materials and technologies in its database, including Entropy Solutions’ PureTemp phase change material.

• U.S. chemical production is thriving, according to an American Chemistry Council analyst, but several factors threaten long-term growth, including equipment shortages and a lack of skilled workers.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Thermochimica Acta:• Thermal stability of renewable diesters as phase change materials

From International Journal of Heat and Mass Transfer:

• Correction of the enthalpy–temperature curve of phase change materials obtained from the T-History method based on a transient heat conduction model

• Thermal performance of cascaded thermal storage with phase-change materials (PCMs). Part I: Steady cases

• A novel multi-dimensional model for solidification process with supercooling

From RSC Advances:

• Synthesis and characterization of novel solid-solid phase change materials with polyurethaneurea copolymer structure for thermal energy storage

From Energy Procedia:

• Energy Accumulation Using Encapsulated Phase Change Materials with Recycled Material Components

From Experimental Thermal and Fluid Science:

• Assessment of a mattress with phase change materials using a thermal and perception test

From Solar Energy Materials and Solar Cells:

• PCM for improving polyurethane-based cool roof membranes durability

• Synthesis and properties of microencapsulated octadecane with silica shell as shape–stabilized thermal energy storage materials

From Applied Thermal Engineering:

• Numerical Investigation on the Heat Transfer Enhancement of a Latent Heat Thermal Energy Storage System with Bundled Tube Structures

From European Thermal Sciences Conference:

• Phase change dispersion, potentially a new class of heat transfer fluids

• Study of improving the thermal response of a construction material containing a phase change material

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 900 of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Ariel Radack Krassner, research assistant at J-SAT Inc., Boulder, Colo.; Rajesh Pednekar, supply chain and operations lead at HSF, India; Sumit Sharma, LabVIEW developer at Central Scientific Instruments Organisation, India; Maarten Heybroek, president of performance technologies and industrial chemicals at Croda International, United Kingdom; and Benjamin Burger, director of product deployment, Sisyan LLC, Mexico.

Benjamin is seeking advice on solar PV thermal storage:

“I’m working with a few engineers on a solar water heating system using photovoltaics (as opposed to solar thermal). I see we may be missing an opportunity to use PCM to store more thermal energy in a smaller footprint.

“I would appreciate any thoughts on this application and if anyone has similar experience or would want to get involved. Below are the key components of the system. A PCM with a melting point around 100-105F would probably be ideal.

“We currently heat water (to be replaced by PCM?) in 55 gallon or 290 gallon insulated plastic tanks (temp always under 140F). The exposed area of the heating elements is titanium. The heat exchanger coil is 316L stainless steel.”