The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

SOLAR + STORAGE

Sunamp, Trina Solar sign deal to combine thermal batteries, heat pumps

Sunamp Ltd. has signed an agreement with Trina Solar to develop an integrated solution combining Sunamp heat batteries now made in Scotland with Trina heat pumps manufactured at a new factory in Changzhou, China.

With more than 14,000 employees, Trina is one of the world’s largest PV panel manufacturers. Sunamp, based in Edinburgh, Scotland, has about 30 employees. Sunamp’s UniQ heat batteries, made at Sunamp’s factory in East Lothian, use a salt-based phase change material to store excess energy generated by solar PV systems. The stored energy is released on demand to provide heat and hot water.

The two companies signed a memo of understanding Oct. 20 at the opening of Trina’s new heat pump factory.

The combined system will use Sunamp’s batteries in conjunction with solar panels and heat pumps to reduce energy costs and carbon emissions. According to Sunamp, the system will offer 23 to 35kWh of storage.

The combined system will use Sunamp’s batteries in conjunction with solar panels and heat pumps to reduce energy costs and carbon emissions. According to Sunamp, the system will offer 23 to 35kWh of storage.

“Our unique heat battery technology extends and enhances the range of capabilities of heat pumps, and the combination of solar PV, heat pumps and heat batteries has exceptional potential to cut fuel costs, address climate change and improve air quality,” said Sunamp CEO Andrew Bissell (right, with Trina Solar VP John Ding).

Sunamp’s heat batteries, which have been installed in thousands of homes across the UK, will be paired with Trina heat pumps as part of a trial of the integrated solution in 20 homes in northern China this winter. If the trial is successful, the integrated solution will be launched in China in the second half of 2019.

The collaboration with Trina is Sunamp’s largest to date, in terms of manufacturing scale and potential revenue. He and Maurizio Zaglio, Sunamp’s international business development manager, provided details on the agreement in phone and email interviews last week.

Q: How did Sunamp make the initial contact with Trina?

A: “Mr Eagle Su and Professor Feng visited our factory earlier in the year. Eagle is the general manager of Trina Energy Management Co. Ltd., which is the section charged with launching Trina into the heat pump market. Professor Feng heads up the Trina Institute of Strategic Studies in Beijing.”

Q: Is the new factory in Changzhou producing Trina’s first heat pumps?

A: “Yes. We signed our memo of understanding at the launch event. We were one of only two non-Chinese Companies invited to the launch (the other was Danfoss). The launch was ‘full on’ with over 1,000 installers visiting the Trina Energy heat pump factory on the Friday and a large indoor event on the Saturday with over 350 attendees, including key management from all leading heat pump vendors in China, local and national government and institutions fully represented, and led in ‘keynote style’ by the CEO of Trina Solar, Jifan Gao.”

Q: What stood out for you on your visit to the factory?

A: “It had very modern, state-of-the-art manufacturing equipment and we were struck by the very full lineup of products ranging from small room-scale to 150kW large commercial/industrial heat pumps. Trina are clearly VERY serious in entering the heat pump market.”

Q: What are the key features of the latest version of the UniQ heat battery?

Q: What are the key features of the latest version of the UniQ heat battery?

A: “They are even more compact and installable than our previous Gen 2 (SunampPV) products … Very flexible on inputs (solar PV, thermal, grid electricity, heat pumps … Two outputs at once (e.g. heating and hot water) … No need for the usual extra plumbing needed with a hot water cylinder … Highest thermal efficiency and A+ rated under Europe’s ErP (Energy-related Products) directive at all sizes UniQ 3, 6, 9 and 12 NB. No range of hot water cylinders is A+ rated across the range. Most can muster a B or A at the smallest size (like 70L, equivalent of the UniQ 3) but this drops off to B, C or D at larger sizes. Sunamp is A+ all the way … They are ready for deep integration to heat pumps via refrigerant loop … We warranty the storage for 10 years … Extremely cost effective on all of lifetime, OpEx and CapEx measures … They look good (much less clutter than water tanks).”

Q: Talk about the PCM used in the battery.

A: “It’s our flagship material, SU58, with a melt point of 58 Celsius, sodium acetate trihydrate, with a couple of components that are there to ensure nucleation and ensure stability. And they do that. [In testing] we’ve reached 40,000 cycles now, which is, we think, pretty convincing at full heat battery scale. These are done on a 2.5 kWh heat battery, full cycle being 40 degrees to 80 degrees back to 40. It still has significantly more than 95 percent capacity at that point. To be honest, we stopped testing. That’s a lifetime’s use for any reasonable product … about 50 years.”

Q: Assuming the trial goes well, will you shift some production to China?

A: “More than likely. It doesn’t make sense to ship things over a huge distance that can be made efficiently and effectively right next to where they can be integrated with the heat pump for the local market. Trina has a very large campus, with three PV factories and the heat pump factory. If they want us to be on that campus, there’s more than enough space.”

Q: The combined system is said offer between 23 and 35kWh of storage. Are those numbers based on tests of full-scale prototypes?

A: “We have fully trialled this kind of heat pump plus heat battery (plus solar PV) in a number of UK test homes. These sizes come from that trial base. A full trial is planned in China over this winter involving Sunamp and led by Trina.”

Q: What excites you most about this opportunity?

A: “The scale of ambition shown by both the Chinese government and Trina in responding to it. 66 million homes in China still source their heat and hot water from coal. This has major impacts on both air quality and carbon emissions leading to climate change. We are really excited to be partnered with Trina in their strategy to address this. And also to be partnered on the wider level with such a leading company.”

PATENTS

Method and mechanisms to use PCMs to improve occupant comfort in vehicles

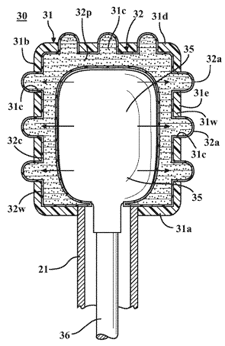

U.S. patent application 20180321703 (applicant Toyota Motor Engineering & Manufacturing North America Inc., Erlanger, Kentucky):

U.S. patent application 20180321703 (applicant Toyota Motor Engineering & Manufacturing North America Inc., Erlanger, Kentucky):

“A temperature moderation apparatus is structured to be positioned in vehicle passenger compartment. The apparatus includes an outer shell defining an interior of the shell, the wall has an exterior surface structured and positioned for physical contact with a skin surface of a vehicle occupant. The outer shell wall also has a plurality of through-holes formed therein. A phase change material element is positioned within the shell interior. The phase change material element includes a stretchable, thermally-conductive outer wall and a quantity of phase change material positioned therein. A pressurization mechanism is coupled to the phase change material element, the pressurization mechanism is structured to pressurize the phase change material element so as to force portions of the phase change material element to extend from the interior of the shell into associated ones of the through holes and past the outer shell wall exterior surface.”

Article of apparel

U.S. patent application 20180317574 (applicant Under Armour Inc., Baltimore, Md.):

“The present invention is directed toward an article of apparel including a base textile with a comfort regulation membrane. The comfort regulation membrane contains a plurality of system-reactive components selectively engaged heat and/or moisture. In an embodiment, the printed coating includes a cooling agent, a phase change material, and a heat dissipation material. The system reactive components may be provided in particulate form, being suspended in a binder. In operation, the article of apparel is effective to delay/diminish the rise in skin temperature (compared to a garment lacking the membrane) and/or improve the overall moisture management capacity of the substrate, either of which may improve wearer comfort.”

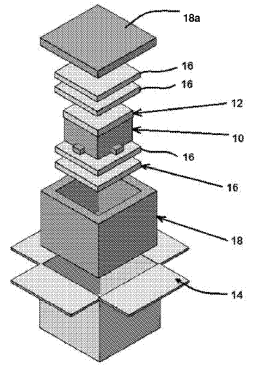

A transportation box

A transportation box

U.S. patent application 20180320947 (inventors Devendra Jain, Nidhi Agarwal, Ravi A.T. Teja and Deepraj Sarmah, Gurgaon, India):

“A transportation box comprising a plurality of first phase change materials (16), a plurality of second phase change materials (20), a first box (18) adapted to enclose a payload box (10), a second box (22) and an outer box (14). The payload box (10) is embedded with the plurality of second phase change materials (20). Further, each of the plurality of first phase change materials (16) is placed above and below the payload box (10). The second box (22) is adapted to contain temperature sensitive products and is nestable within the payload box (10). The first box (18) is nestable within the outer box (14). The plurality of first phase change materials (16) and the plurality of second phase change materials (20) are arranged in a manner such that air in between controls heat flow into and within the first box (18).”

Thermal storage units and methods of making and using them

U.S. patent application 20180320987 (applicant University of Texas Board of Regents, Austin, Texas):

“Sugar alcohol blends of galactitol and mannitol and compositions comprising such blends are disclosed as phase change materials (PCMs). A method of forming carbon nanotubes on a carbon substrate is described. Carbon substrates with carbon nanotubes, in particular, conformal layers of carbon nanotubes on carbon substrates, are also disclosed, as are methods of making and using these materials. Thermal storage units are also provided. The thermal storage units can comprise a heat exchange path through which a heat exchange medium flows, and a thermal storage medium in thermal contact with the heat exchange path.”

IN BRIEF

• Members of the RAL Quality Association PCM will meet in Dusseldorf on Thursday, Nov. 15. The agenda includes discussions on quality and testing specifications; reference materials in calorimetry; PCM product certification; and the promotion of PCM products in the European Union, Germany, Netherlands and the United States.

• A 10-day reliability test has been completed at the 150MW Noor Ouarzazate III concentrated solar power plant in Morocco. The plant’s molten salt storage system is designed to produce electricity in the absence of sunlight for 7.5 hours. During the test, the plant output over 13.2 GWh to the grid.

• Kathu Solar Park, the 100MW concentrated solar power plant in South Africa’s Northern Cape Province, has begun generating steam, an important step in the plant’s commissioning process. The plant uses molten salt to store heat from the solar field for up to 4.5 hours. The heat can be recovered to produce steam and generate electricity.

• The agenda is taking shape for the 3rd Sustainable Oils & Fats International Congress, to be held April 4-5, 2019, in Paris. Among the topics: “Sourcing & Production of Sustainable Oils & Fats” and “Creating, Maintaining, Controlling Sustainable Supply Chain.”

• Emirates Central Cooling Systems Corp. says it is on track to establish the world’s largest district cooling project by increasing its capacity of district cooling in Business Bay, Dubai. Business Bay is now served by three major district cooling plants with a total capacity of 135,000 refrigeration tons. The addition of three more plants will bring the collective capacity to 350,000 RT.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Energy:• Preparation and thermal properties of sodium acetate trihydrate as a novel phase change material for energy storage

From Journal of Building Engineering:

• The Palm Kernel Vegetable Fat: a Low-cost Bio-based Phase Change Material for Thermal Energy Storage in Buildings

From International Journal of Applied Engineering Research:

• Carbonaceous Phase Change Nanocomposites: A low cost energy storage approach [pdf]

From Applied Mathematical Modelling:

• Investigation of Phase Change in a Spiral-Fin Heat Exchanger

From Applied Energy:

• Numerical investigation of the thermal performance enhancement of latent heat thermal energy storage using longitudinal rectangular fins and flat micro-heat pipe arrays

From Applied Thermal Engineering:

• Thermal properties and applications of microencapsulated PCM for thermal energy storage: A review

From International Journal of Heat and Mass Transfer:

• Evaluation and optimization of thermal performance for a finned double tube latent heat thermal energy storage

• Influence of gas compressibility on gas flow through bed of granular phase change material

From Sustainable Cities and Society:

• Effective latent heat thermal energy storage system using thin flexible pouches

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,380 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,380 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Yifei Wang, a Ph.D. candidate “working at the intersection of photonics and nanotechnology” at Stanford University in California.