The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

RESEARCH

Hybrid sensible-latent heat storage concept achieves high energy densities

Chistoph Zauner, a research scientist at the Austrian Institute of Technology, has been investigating the use of phase change material for a variety of applications since 2010. His most recent papers include “Experimental characterization and simulation of a hybrid sensible-latent heat storage,” published earlier this year in Applied Energy. He discussed his work in an email interview.

Chistoph Zauner, a research scientist at the Austrian Institute of Technology, has been investigating the use of phase change material for a variety of applications since 2010. His most recent papers include “Experimental characterization and simulation of a hybrid sensible-latent heat storage,” published earlier this year in Applied Energy. He discussed his work in an email interview.

Q: How did you first become interested in phase change material?

A: I worked for quite some time in the field of solar thermal energy and was especially focusing on industrial application with non-standard solar collector, so-called medium temperature collectors. This more efficient class of collectors (concentrating and non-concentrating) can produce temperature up to 250° C heating pressurized water, oil and generate steam. In order to achieve high solar fractions (i.e. cover much more than 10% of the total required process energy by solar energy), one needs to store energy. Standard storages (steam, oil, water) have limitations and latent storage certain advantages. Thus, we started developing such storages. In the meantime, we want to use it for a much broader range of applications (not only solar thermal).

Q: Describe the hybrid sensible-latent heat storage concept you have been working on.

A: In our new concept, we place the PCM inside the tubes of a modified shell-and-tube heat exchanger [shown above]. This is in contrast to the well-known approach of placing it outside. On the shell side we use a heat transfer fluid (in our first prototype we used oil) which at the same time serves as a sensible storage medium. Thus, we achieve a hybrid sensible-latent heat storage, which offers several opportunities:

• Heat transfer fluid (in our case oil) and PCM fractions can be varied over a wide range, i.e. a hybrid sensible-latent heat storage is realized. Advantages of both domains can be exploited, such as high energy density of the PCM and high power density of sensible storages

• Fewer weld seams as for the standard concept (PCM outside many small tubes) leads to storage cost reduction

• Larger heat transfer area between tubes and PCM enables higher storage power

• Our tubes serve as a macroencapsulation of the PCM, which serves as protection and increases storage lifetime.

Q: Is HDPE in use as a PCM in any commercialized application?

A: HDPE is a so-called commodity plastics. It is the kind of polymer used most out of all polymers. As such it is produced in a multi-million-ton scale each year. Also a versatile recycling industry is in place, which allows for further cost reduction potential (we know which types are suitable and which ones are not). Usually HDPE is used to contain PCMs only. There are no commercial applications yet, where HDPE is used as PCM. Currently we are investigating various possible applications.

A 40 kWh, 100 kW peak power hybrid latent-sensible storage system was successfully tested at AIT labs at temperatures up to 200 °C. |

A: Apart from the advantages mentioned above, there is one particular key advantage over packed beds: packing density. Our storage can achieve up to 90% PCM volume density, whereas the theoretical limit for ideally packed spheres is 74%. In a packed bed, however, one does not have “ideal packing,” but the situation of “random packing,” where PCM volume fractions of 64% are achieved.

We found a certain way, which we do not disclose, how to actually fill up the whole tubes even for the crystallized (shrinked) PCM. Usually, PCM macroencapsulations are filled up to 100% only in the molten state, which further reduces the final volume PCM fraction of the whole storage (i.e. kWh/m3).

Q: Would a sharper phase change peak be advantageous to the proposed application? How would this also affect the Stefan model?

A: We already designed storages for different applications (various combinations of low/high power, low/high capacity, different temperature levels). Sometimes it is very important to actually have a PCM with a sharp peak and sometimes even large subcooling doesn’t matter. It depends on the application.

Of course, one has to be careful by applying the various models (not only the Stefan model) and not to spoil the underlying assumptions. We learned a lot in that direction by comparing experimental storage data to simulations and know now very well where the limits are.

Q: What are the next steps in your investigation of this storage concept for district heating networks and industrial processes? How close is it to possible commercialization?

A: It is important to emphasize that AIT is not a university, but more like a real company which has to do “real business” and earn “real money.” We do business in various ways and offer different business models.

This ranges from material characterization or simulations directly done (and paid) by customers. We also offer storage engineering using our models and experimental know-how to storage manufacturers. We also demonstrate storages at real demo sites (currently we have projects in polymer extrusion and aluminum die casting) and evaluate their potential in various companies (e.g. we are currently investing a specific process in steel industry using a PCM-steam-storage concept).

We can provide various services or even serve as a “one-stop-shop” for energy optimization of industrial processes using storages. This starts from analyzing the process in detail (incl. monitoring), designing the storage (including integration), organization of storage manufacturing, integration at the plant and commissioning. Also this includes financing aspects (contracting, subsidies, R&D projects etc.).

The storages are permanently optimized but can be bought right away as we are only using industrially available PCMs (we also tested [PureTemp PCMs] and might use them, of course) and heat exchanger/storage manufacturing techniques.

Q: What other projects are you working on that might be of interest to the PCM community?

A: We also work on “overheating solutions” using PCM. Some articles have been published in that direction already, including “High temperature phase change materials for the overheating protection of facade integrated solar thermal collectors.” Also, we employ PCMs in car batteries and developed concepts there. We simulated and tested various prototypes of real batteries.

A related topic is development of new insulations, especially aerogel-based. This is very much needed for storages and also for energy efficiency in industries (“stop wasting energy first, then re-use it!”).

[For more examples, see www.ait.ac.at/en/research-fields/sustainable-thermal-energy-systems/projects/storeitup-if.]

We are very much looking for partners for new PCMs. We do not produce them on our own. However, we do some development with partners on organic PCMs.

[An extended version of this interview is posted on the Phase Change Matters blog.]

PATENTS

Refrigerator with a phase change material as a thermal store

U.S. patent application 20170314839 (applicant Enviro-Cool Commercial Ltd., Tonbridge, Great Britain):

“A refrigerator having a thermal store comprising a phase change material is disclosed. The refrigerator has a cooling chamber for containing an object to be cooled, and a vapor compression refrigeration system including a first evaporator for cooling the cooling chamber and a second evaporator for cooling the phase change material. A valve is provided to control the flow of refrigerant to the first and second evaporators depending on the cooling load on the refrigerator. When the refrigerator is subject to a relatively low cooling load, refrigerant flows to the second evaporator to cool the phase change material and, when the refrigerator is subject to a relatively high cooling load, refrigerant flows to the first evaporator such that increased cooling is provided to the cooling chamber by the first evaporator and the phase change material.”

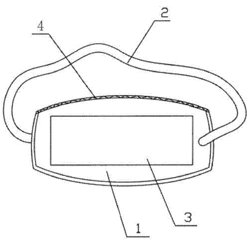

Hyperthermia therapy mask

U.S. patent application 20170312122 (applicant First Affiliated Hospital of Guangzhou Medical University, Guangzhou, China):

“The present invention relates to a hyperthermia mask used in the field of medical appliances. The hyperthermia mask of the present invention comprises a mask surface body and a tensioning belt, the mask surface body is made of phase change fibers or the mask surface body is filled with the phase change fibers; the phase change fibers are composed of hollow fibers and phase change materials filled into the hollow fibers; and the phase change materials have a phase change temperature of 40° C. to 55° C. The hyperthermia mask of the present invention is prepared based on phase change heat storage, is convenient to use and has a good hyperthermia effect.”

“The present invention relates to a hyperthermia mask used in the field of medical appliances. The hyperthermia mask of the present invention comprises a mask surface body and a tensioning belt, the mask surface body is made of phase change fibers or the mask surface body is filled with the phase change fibers; the phase change fibers are composed of hollow fibers and phase change materials filled into the hollow fibers; and the phase change materials have a phase change temperature of 40° C. to 55° C. The hyperthermia mask of the present invention is prepared based on phase change heat storage, is convenient to use and has a good hyperthermia effect.”

IN BRIEF

• A recent survey by Reaxys found that many chemists don’t think the field is innovative enough. Eighty percent said there is too much emphasis on research with industrial applications, which is stifling innovation. Reaxys is a chemistry research tool developed by Elsevier.

• Min Zhu, assistant professor of textile development and marketing at the Fashion Institute of Technology, will speak about the future of phase change materials at a textiles conference in New York City Nov. 8.

• Lufthansa Cargo has partnered with va-Q-tec AG to offer the temperature-controlled specialist’s va-Q-tainer thermal containers across the German carrier’s global network.

• Scientists investigating how scavenging animals are adapting to monoculture palm oil plantations in Borneo were surprised by what turned up in their traps. “In the jungles and border regions, the team found animals such as civets, otters, mongooses and pigs,” Oils & Fats International magazine reports. “But the closer they got to the plantations where the land had been disturbed and human activity was frequent, the fewer species they found until only one stood out – the Southeast Asian water monitor.” The big lizards are thriving, thanks to a plentiful supply of food and less competition from mammalian scavengers and predators.

• Researchers at the University of Maryland have developed a thermally conductive and strong textile from fibers of aligned boron nitride nanosheets embedded in a polymer matrix that can cool a person down by up to 2° C.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Molecular Catalysis:• Combining biocatalysts to achieve new phase change materials. Application to non-edible animal fat

From Energy and Buildings:

• Performance evaluation of dual phase change material gypsum board for the reduction of temperature swings in a building prototype in composite climate

From Colloids and Surfaces A: Physicochemical and Engineering Aspects:

• Low cracking ratio of paraffin microcapsules shelled by hydroxyl terminated polydimethylsiloxane modified melamine-formaldehyde resin

From Energy Conversion and Management:

• Numerical and experimental research of cold storage for a novel expanded perlite-based shape-stabilized phase change material wallboard used in building

From Procedia Engineering:

• Thickness Determination of a Three-layer Wall with Phase Change Materials in a Chinese Solar Greenhouse

• Experimental Study on Thermal Performance Improvement of Building Envelopes Integrated with Phase Change Materials in an Air-conditioned Room

• Phase Change Humidity Control Material and its Application in Buildings

From Energy:

• Performance Enhancement of a Building-Integrated Photovoltaic Module Using Phase Change Material

From Materials Today:

• Step by Step Methodology for the Assessment of Metal Corrosion Rate with PCMs Suitable for Low Temperature Heat Storage Applications

From Thermal Science and Engineering Progress:

• Investigation of the effect on the efficiency of phase change material placed in solar collector tank

From Applied Thermal Engineering:

• Generalized diagrams of energy storage efficiency for latent heat thermal storage system in concentrated solar power plant

From Energy Procedia:

• Thermal energy storage with phase change materials to increase the efficiency of solar photovoltaic modules

• Development of industrial PCM heat storage lab prototype

• High Power Latent Heat Storages With 3D Wire Structures – Numerical Evaluation Of Phase Change Behavior

• Experimental comparison of two heat exchanger concepts for latent heat storage applications

• Erythritol, glycerol, their blends, and olive oil, as sustainable phase change materials

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,160 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Min Zhu, assistant professor of fashion and marketing at Fashion Institute of Technology, New York; William Barg, engineer at SunDanzer Refrigeration Inc., Tucson, Ariz.; Vincenza Brancato, materials engineer at Italy’s National Research Council; Judy Vella, vice president for innovation and product development at Comfort Revolution, West Long Branch, N.J.; and Thomas Schwab, chief operating officer at va-Q-tec AG, Würzburg, Germany.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Min Zhu, assistant professor of fashion and marketing at Fashion Institute of Technology, New York; William Barg, engineer at SunDanzer Refrigeration Inc., Tucson, Ariz.; Vincenza Brancato, materials engineer at Italy’s National Research Council; Judy Vella, vice president for innovation and product development at Comfort Revolution, West Long Branch, N.J.; and Thomas Schwab, chief operating officer at va-Q-tec AG, Würzburg, Germany.