The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

NEW PRODUCTS

Croda began work on new microencapsulated PCM four years ago

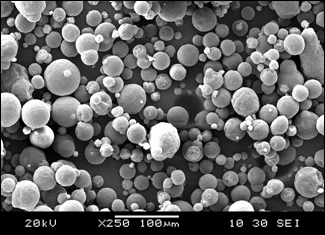

UK-based Croda International recently announced the launch of a microencapsulated form of biobased phase change material developed at the company’s PCM technical center in Netherlands. The new material is designed to be used to control temperatures in bedding, mattresses, automotive interiors, clothing and other applications.

The development was led by Marco Auerbach and Jerome Gonthier, working with colleagues who have expertise in microencapsulation and acrylic polymer. Martin Butters, a specialist in PCM applications and business development, also supported the project.

The development was led by Marco Auerbach and Jerome Gonthier, working with colleagues who have expertise in microencapsulation and acrylic polymer. Martin Butters, a specialist in PCM applications and business development, also supported the project.

Gonthier and Butters provided details on the new material in an email interview.

Q: What prompted the decision to develop this technology?

A: “Having established a range of high quality bio-based PCMs, market demand led us to explore the microencapsulation of these PCMs. Microencapsulation converts the PCM into particles that are offered to the market in two forms, powder and water-based dispersion. Microencapsulated PCMs are often advantageous for use in composite materials such as coatings, fibers and other matrices where PCM leakage needs to be avoided.”

Q: How long did it take to complete the project?

A: “Overall the project ran for about four years leading to the launch of the first products in 2018.”

Q: Did the team surmount any unexpected challenges, technical or otherwise?

A: “The challenges were mainly those we expected – achieving microcapsules with good durability, very low levels of free wax and overcoming sub-cooling (reduction in crystallisation temperature due to microencapsulation).”

Q: When did Croda officially launch the technology commercially?

A: “The first products, CrodaTherm ME 29D (50% dispersion) and CrodaTherm ME 29P (powder), which are 29º C melting point products, were launched in Q4 2018. 32º C versions will be added to the range shortly and we expect the range to be further extended with other operating temperatures in due course.”

A: “The first products, CrodaTherm ME 29D (50% dispersion) and CrodaTherm ME 29P (powder), which are 29º C melting point products, were launched in Q4 2018. 32º C versions will be added to the range shortly and we expect the range to be further extended with other operating temperatures in due course.”

Q: Does Croda manufacture fibers and textiles with the microencapsulated PCM? Or does it manufacture the MPCM and sell it to fiber and textile manufacturers?

A: “Croda does not produce fibers or textiles, instead we specialize in offering PCMs that are developed and manufactured in-house, for use in such applications (and many more).”

Q: What specs can you share on the MPCM, such as composition, peak melt point and latent heat storage capacity?

A: “We microencapsulate CrodaTherm bio-based PCMs with an acrylic-type shell. For CrodaTherm ME 29D and ME 29P, peak melting temperature is 29º C and latent heat is typically about 180 J/g.”

Q: Does the MPCM have any properties, such as latent heat storage capacity or ease of manufacture, that sets it apart from competing products?

A: “We use internally produced bio-based PCM, rather than paraffin waxes sourced externally from the market, meaning we have full control over quality and the products have high bio-based content and excellent thermal properties.”

Q: Have textiles embedded with this MPCM undergone thermal effusivity testing or other tests that would confirm their effectiveness in managing temperatures in consumer products?

A: “Several tests have been carried out to confirm the performance of materials embedded with mPCM and further work will be carried out, including thermal effusivity.”

Q: Will the technology be used in any products scheduled for release this year or next?

A: “A number of projects are underway for different applications, so we’ll have to wait and see!”

PATENTS

Pouch filled with PCM for use in crockery

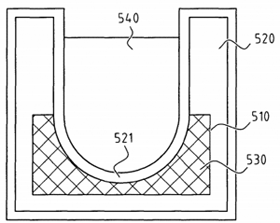

U.S. patent application 20190223636 (applicant Probalco BVBA, Kortrijk, Belgium):

U.S. patent application 20190223636 (applicant Probalco BVBA, Kortrijk, Belgium):

“A pouch [510] filled with phase-change material [530], wherein the pouch comprises a preformed first wall [521] and a second wall, wherein the first wall comprises a bowl-shaped part, in which the phase-change material is accommodated, and a peripheral part, wherein the second wall is attached to the peripheral part of the first wall, wherein a high vacuum prevails in the pouch, and wherein the pouch is intended for placing against a wall to be heated or cooled. … The present invention further relates to crockery provided with a pouch filled with phase-change material.”

PCM-based enhancement for reversed-cycle defrosting

U.S. patent application 20190226735 (applicant Sunamp Ltd., Lothian, Great Britain):

“A thermal energy storage system in the form of a reverse-cycle defrosting vapour compression system suitable for use with systems adapted to transfer heat from at least one heat source to at least one heat sink (heat transfer system), wherein said thermal energy storage system comprises: at least two thermal energy storage units; said thermal energy storage units comprise a thermal store comprising a heat exchanger with the storage units comprising a primary coil and a secondary coil; the primary coil is dedicated for use with refrigerant fluids and is adapted for inter-connection to both a condenser and a pressure-lowering device for use with a heat transfer system; the secondary coil is dedicated for use with heat transfer fluids and wherein said secondary coils are adapted to exchange heat with the phase change material in each thermal storage unit; said primary and secondary coils are surrounded by a suitable phase change material.”

Water-based thermal cooling gels with viscosity modifier

U.S. patent application 20190225853 (applicant Microtek Laboratories, Dayton, Ohio):

“Thermal cooling gel and cold packs enclosing such thermal cooling gel have an aqueous gel of 1% to 10% wt/wt of cellulose, 0.5 g/L to 2 g/L of an ice nucleating protein, and a biocide. The enthalpy of the thermal cooling gel is in a range of 250 J/g to 330 J/g.”

IN BRIEF

• PureTemp-enhanced fabrics were among the new materials presented at a gathering of architects, designers and journalists at the MatériO library in Paris this week. The materials library, which also has showrooms in Brussels, Seoul and Shanghai, lists thousands of “cutting edge” materials and technologies in its online database, including PureTemp’s biobased PCM.

• Southern Research opened the new Energy Storage Research Center on its engineering campus in Birmingham, Ala., this month. The center will work to speed the development of clean and sustainable energy storage technology, including thermal energy storage systems.

• Ecozen Solutions of India, which makes portable solar cold rooms for use on small farms, recently closed a Series A round of funding from investors including impact investment fund manager Caspian and Hivos-Triodos Fund, which is affiliated with Netherlands-based Triodos Bank. Omnivore Capital Management Advisors, which originally invested in Ecozen in 2015, also participated in the round, AgFunder News reports. The solar cold room’s thermal storage unit can store power for more than 36 hours in case of cloudy or rainy weather.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From International Journal of Energy Research:• Design of diatomite‐based hydrated salt composites with low supercooling degree and enhanced heat transfer for thermal energy storage

From Journal of Physical Chemistry B:

• Clusters in Liquid Fatty Acids: Structure and Role in Nucleation

From Construction and Building Materials:

• Development of thermal energy storage lightweight structural cementitious composites by means of macro-encapsulated PCM

• Preparation of microencapsulated phase change materials used graphene oxide to improve thermal stability and its incorporation in gypsum materials

From Journal of Power and Energy:

• Numerical modelling of phase change material melting process embedded in porous media: Effect of heat storage size

From Advanced Materials Interfaces:

• Phase Change Materials: Doubly Coated, Organic–Inorganic Paraffin Phase Change Materials: Zinc Oxide Coating of Hermetically Encapsulated Paraffins

From NASA Technical Reports Server:

• Utilization of Micro Tube Heat Exchanger for Next Generation Phase Change Material Heat Exchanger Development

From SN Applied Sciences:

• Encapsulation of paraffin wax by rigid cross-linked poly (styrene divinylbenzene-acrylic acid) and its thermal characterization

From Energy Conversion and Management:

• Transient performance of a Peltier super cooler under varied electric pulse conditions with phase change material

From Applied Thermal Engineering:

• Thermal optimization of a kirigami-patterned wearable lithium-ion battery based on a novel design of composite phase change material

• An experimental and theoretical study of the solidification process of phase change materials in a horizontal annular enclosure

From Journal of Energy Storage:

• Enhancement of the thermal energy storage capacity of a parabolic dish concentrated solar receiver using phase change materials

From Renewable Energy:

• Numerical simulation on the thermal performance of a PCM-containing ventilation system with a continuous change in inlet air temperature

From Energy Fuels:

• Graphene modified hydrate salt/UV-curable resin form-stable phase change materials: continuously adjustable phase change temperature and ultrafast solar-to-thermal conversion

From Journal of Industrial and Chemical Engineering:

• Thermal performance enhancement of a phase change material with expanded graphite via ultrasonication

From Chemistry Select:

• Microencapsulation of Stearic Acid into Strontium Titanate Shell by Sol‐Gel Approach for Thermal Energy Storage

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,480 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,480 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Morten Veis (Thomsen) Donnerup, CEO and co-founder at Suntherm, Hojslev, Denmark; Afelio Padilla, COO at Ignitus, Guadalajara, Spain; and Laurent Destouches, founding director at Solutions Composites, Mettray, France.