The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

RESEARCH AND DEVELOPMENT

Entropy develops shape-stabilized versions of 2 PureTemp PCMs

Entropy Solutions has developed shape-stabilized versions of two of its PureTemp biobased phase change materials. These “gelled” PCMs maintain their shape even as the PCM cycles between solid and liquid form, absorbing, storing and releasing thermal energy as needed in temperature-control applications. Potential uses include building materials, underfloor electric heating systems and shipping containers.

The gelled PureTemp 4, right, has a latent heat of 159.4 joules per gram, a melt point of 4.81º Celsius and a freeze point of 1.07º Celsius. The gelled PureTemp 20 has a latent heat of 149.3 J/g, a melt point of 21.39º C and a freeze point of 16.85º C. The addition of polymers accounts for the observed reductions in latent heat compared to the ungelled versions.

The gelled PureTemp 4, right, has a latent heat of 159.4 joules per gram, a melt point of 4.81º Celsius and a freeze point of 1.07º Celsius. The gelled PureTemp 20 has a latent heat of 149.3 J/g, a melt point of 21.39º C and a freeze point of 16.85º C. The addition of polymers accounts for the observed reductions in latent heat compared to the ungelled versions.

The gelled forms ensure even distribution of PCMs contained in thin films. The PCM does not leak from the polymer matrix after thermal cycling. Other properties of these lab-scale versions include:

• Moldable

• Narrow melting range

• Soft when the PCM is in the liquid state

• Stiff/hard when the PCM is in the solid state

• Minimized leakage if enclosing film is punctured

Entropy Solutions is exploring scale-up and commercialization options for the new material.

OFFBEAT

PCM-powered cooling vest keeps ‘furry’ Australian comfy, in character

Every week, Entropy Solutions fields dozens of routine questions about phase change material. Is PureTemp 68 available in solid plates/blocks? What is the price for 10kg of PureTemp 151 delivered to Austria? Could you provide us with a price per ton for PureTemp 58? Do you have any agents or resellers in South Africa?

Last month, one inquiry stood out. Chris of Australia wrote:

“I have been using PCM in sealed plastic as part of a cool down vest. Recently I have noticed the liquid color has changed to blue and I have no idea why. While not in storage they are stored in a freezer or fridge, but while I’m away using them at a convention with no access to a fridge or freezer I store them in icewater in a blue Eskimo cooler. Does this affect the color change and can this affect its freezing process?”

Using them at a convention?

I pondered what type of convention might attract a cooling vest user. A gathering of public safety workers, perhaps? BMX racers? Oil field crews? People with multiple sclerosis? In Chris’ case, it turned out to be none of the above.

The pseudonym in his email address provided an intriguing clue: Reylith Pawpad. I had to know more.

I Googled “Reylith Pawpad” and learned that Chris is a member of the “furry” community, folks who appear at public events in anthropomorphic costumes. His Reylith Pawpad character is a lemox, a lemur-fox hybrid with orange-and-white fur and big eyes. In a 2012 interview posted on YouTube, Chris said he bought the costume for $2,000 from a Florida “fursuit” maker. He uses his cooling vest with a red heeler costume, shown here.

Chris and I exchanged a series of emails that opened my eyes to a niche market for phase change materials:

Chris and I exchanged a series of emails that opened my eyes to a niche market for phase change materials:

Ben: What brand of cooling vest?

Chris: I purchased the vest from EZcooldown in Europe.

Ben: Have you tried contacting them? Also, how old is the vest? I checked the EZCooldown website and found they used petroleum-based Techniche 15°C PCM inserts until late last year. They switched to “organic” PCMs in January 2016. The new inserts are available in two temperatures: 15°C and 21°C. I’m guessing you have the petroleum-based 15°C inserts.

Chris: I contacted EZcooldown about the inserts. Here is what they emailed back: “The casings of our 1st generation PCM inserts can absorb color from other fabrics or materials. This has no influence on the performance of the PCM inserts.”

Ben: Pleased to see you were able to get to the bottom of this. So the casings changed color, not the PCM? I wonder what material they were using. I’d like to post a brief item on your use of a cooling vest for my PCM blog. Would you be interested in participating in a brief email interview?

Chris: Sure thing, Ben.

Ben: Thanks, Chris. Please pardon the basic nature of some of the questions; I’m new to the furry culture. What’s your full name, age and city?

Chris: So my name is Chris F. Not 100% comfortable having my last name published. Sorry, hope this will suffice. I’m 27 years old and I’m living in the city of Logan in Queensland.

Ben: How long have you participated in the furry community?

Chris: I have been an active member of the furry community since December 2009.

Ben: What’s the major appeal for you?

Chris: The main appeal of getting into character and costume is more of a extension of myself as well as a way to break down walls that restrict the way I interact with people. The reactions are generally positive as most people stop to take a photo with me or have their kids have a photo with me. Making people smile is the goal. On smaller excursions in the costume I interact more with the public.

Ben: Aside from conventions, in what other contexts do you wear your costumes (street fairs, parties, etc)?

Chris: Meets and gatherings in our community as well as charity events. Our two most recent events were the advanced screening of Disney‘s “Zootopia” at our local cinema and a convention called Furry Down Under on the Gold Coast.

Ben: How long have you been using a cooling vest?

Chris: I have been using EZcooldown’s vest for about a year or so now and it makes a dramatic difference. This is the first cooling vest that I have bought. Other friends have highly recommended it. Very few in the community actually own a vest, as they aren’t cheap. The brand that we buy is specifically designed for our fursuits.

Indeed, EZcooldown markets a $178 cooling vest to “actors, cosplayers, LARPers, fursuiters and other costume performers.” Glacier Tek and other manufacturers target this niche with similar concealable vests. Looks like a growth opportunity for the cooling vest industry. Whether you’re a fursuiter, a sports mascot, Barney the Dinosaur or just some Mickey Mouse character, it gets hot inside those costumes.

PRODUCT LAUNCH

ThermoSafe introduces Certis temperature-controlled packaging line

Sonoco ThermoSafe has launched a line of three- and five-day temperature-controlled packaging solutions for the distribution of pharmaceuticals and biologics.

The Certis platform is for products that require 2-8°C, 15-25°C and frozen temperature control. A universal pack-out configuration is designed for use in hot and cold seasons while meeting the demands of long-distance shipments. All refrigerated solutions use PureTemp 4, and all controlled-room temperature solutions use PureTemp 20.

The Certis platform is for products that require 2-8°C, 15-25°C and frozen temperature control. A universal pack-out configuration is designed for use in hot and cold seasons while meeting the demands of long-distance shipments. All refrigerated solutions use PureTemp 4, and all controlled-room temperature solutions use PureTemp 20.

“The Certis platform revolutionizes inventory management and reduces total cost of ownership by utilizing three types of refrigerants and eight shippers to create 24 shipping solutions,” said Vishal Khushalani, director of global marketing and business development, Sonoco ThermoSafe.

PATENTS

Strontium bromide phase change material

U.S. patent application 20160200956 (applicant SunAmp Ltd., Scotland):

“There is herein described a phase change material (PCM) for use in energy storage systems. More particularly, there is described a phase change material comprising Strontium Bromide and a Metal Halide that is optimal to storing heat in about the 76° C. to 88° C. temperature range.”

Thermal energy storage assembly with phase change material

U.S. patent application 20160201931 (applicant Carrier Corp., Farmington, Conn.):

“A thermal energy storage assembly includes a first pipe configured to have a heat transfer fluid flow through a bore of the first pipe and a second pipe surrounding the first pipe. A phase change material fills the space between the first pipe and the second pipe, the phase change material storing cold thermal energy from the heat transfer fluid.”

TES system combining sensible heat solid material and PCM

U.S. patent application 20160201995 (applicant Polytechnic University of Catalonia, Spain):

“The invention relates to a system for the storage and recovery of thermal energy, using, as its medium, at least one phase change material (solid-liquid) and a sensible heat solid material for storing/recovering the heat obtained from an external source in the form of phase change latent heat and sensible heat. The aforementioned materials are duly housed inside a single tank containing at least two zones which are differentiated by the range of temperatures to which they are subjected, each zone containing a different material. The most common configuration consists of three different zones located inside the tank, namely: a hot zone in the upper part of the tank, enclosing an encapsulated phase change material characterised by a high melting temperature; a cold zone housed in the lower part of the tank, containing a phase change material with a low melting temperature; and a middle zone containing a sensible heat solid material.”

PCM-based energy storage devices and systems

U.S. patent application 20160201996 (applicant Verdicorp LLC, Tallahassee, Fla.):

“Devices and methods for using phase-change-materials to store and retrieve energy. Specifically, the invention discloses various containment devices that may be used to enclose a mass of phase-change-material. The disclosure describes ways it which these devices may be manufactured and ways in which they may be used. The storage devices preferably create an enclosed volume that eliminates any mixing between the phase-change material and any surrounding material such as thermal oil.”

IN BRIEF

• In a LinkedIn post, DLR Group engineer Steve Reigh notes that significant changes are taking shape in Washington state’s energy code. Starting in July 2017, air-handling units in high-efficiency variable air volume systems “must have either a maximum size of 20% of the total cooling capacity (5 chillers!), OR thermal storage sized for a minimum of 20% of the total cooling capacity! It shows that the energy code writing groups are thinking about thermal storage, and it may start to creep into other parts of the energy code in future iterations.”

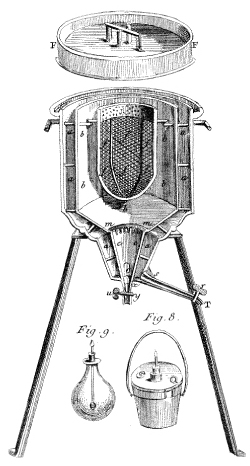

• In the late 18th century, Antoine-Laurent de Lavoisier and Pierre-Simon Laplace of France designed the first calorimeter, a multichamber device that used ice to measure the amount of heat given off during combustion or respiration. Guinea pigs provided the heat in early experiments. Andrea Sella, a professor of chemistry at University College London, takes a look at the fascinating origin of the instrument.

• In the late 18th century, Antoine-Laurent de Lavoisier and Pierre-Simon Laplace of France designed the first calorimeter, a multichamber device that used ice to measure the amount of heat given off during combustion or respiration. Guinea pigs provided the heat in early experiments. Andrea Sella, a professor of chemistry at University College London, takes a look at the fascinating origin of the instrument.

• New from QY Research: “Global Phase Change Materials Consumption 2016 Market Research Report.” BASF, Rubitherm, Croda, Pluss and Entropy Solutions are among the major manufacturers profiled.

• Britain’s exit from the European Union could complicate the task of complying with Europe’s network of chemical regulations, writes Michael Ravenscroft in IHS Chemical Week magazine.

• PCM maker Entropy Solutions recently received ISO 9001: 2008 certification for its quality management system. The ISO 9001 standard is designed to help ensure that an organization’s products and services consistently meet customer requirements, and that the quality system of the organization continues to improve.

• Innovative Solutions Corp., maker of Infinite R phase change material, will hold a presentation titled “Improving Your Building’s Envelope,” in Kansas City, Mo., on Aug. 9. The presentation will cover how PCMs can increase occupant comfort while dramatically reducing heating and cooling costs. Cost: $5.

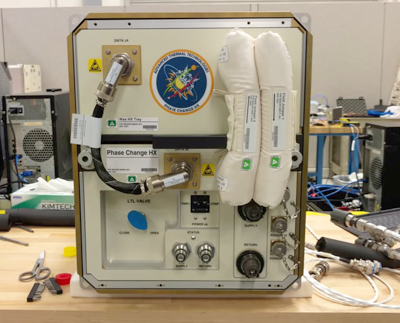

• Inverse.com has posted a fresh photo of PCM HX, one of the NASA experiments headed for the International Space Station next week aboard SpaceX.

• Inverse.com has posted a fresh photo of PCM HX, one of the NASA experiments headed for the International Space Station next week aboard SpaceX.

• SolarReserve‘s Crescent Dunes CSP plant is the subject of a Scientific American piece this week. The Nevada plant, which uses molten salt to store more than 10 hours of electricity and make it available on demand, “has achieved what engineers and proponents of renewable energy have struggled with for decades: providing cheap, commercial-scale, non–fossil fuel electricity even when winds are calm or the sun is not shining.”

• In an interview with Sustainable Brands, Dow Chemical‘s chief sustainability officer says the company has significantly increased sales of products that use sustainable chemistry over the past 10 years.

• Updated research from Future Market Insights: “Temperature Controlled Packaging Solutions Market: Global Industry Analysis and Opportunity Assessment 2015-2025.”

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Applied Energy:• Energy storage technologies and real life applications – A state of the art review

• Thermal energy storage (TES) for industrial waste heat (IWH) recovery: A review

From Construction and Building Materials:

• Thermal performance and cost analysis of mortars made with PCM and different binders

• Study on anti-freezing functional design of phase change and temperature control composite bridge decks

From Applied Thermal Engineering:

• Preparation and characterization of sepiolite-based phase change material nanocomposites for thermal energy storage

From International Journal of Heat and Mass Transfer:

• Melting of nano-phase change material inside a porous enclosure

From Solar Energy Materials and Solar Cells:

• Synthesis, characterization and properties of palmitic acid/high density polyethylene/graphene nanoplatelets composites as form-stable phase change materials

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 800 of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Marcel Thran, development and service engineer at DoKaSch GmbH, Germany; Susan Bell, CEO at Sustainable Education Corp., Fort Mill, S.C.; and Oliver Osters of Deutsche ACCUmotive GmbH, Germany.