The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

AWARDS

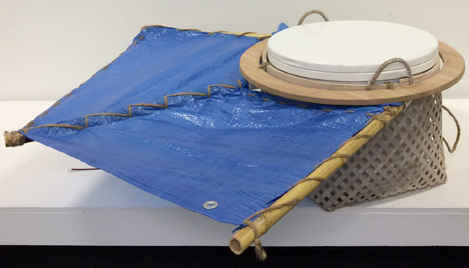

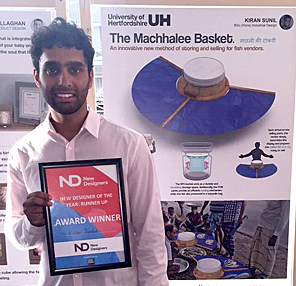

UK student’s mobile cooler for fish vendors wins design honor

A University of Hertfordshire student who designed a fish cooler for street vendors is the runner-up in the UK’s prestigious New Designer of the Year competition. The New Designers exhibition, now in its 32nd year, features the work of top students from the UK’s leading design schools.

Kiran Sunil’s “Machhalee Basket” is essentially an EPS cooler equipped with phase change material. Judges described it as “a sensitively designed product – an example of bottom-up, frugal innovation, demonstrating genuine social impact and purpose.” The award includes a cash prize of £500.

Sunil, 22, was born and raised in the United Kingdom and is of South Indian descent. He recently earned an industrial design degree at Hertfordshire. He discussed details of his final-year project in an email interview.

Q: What does “Machhalee” mean?

Q: What does “Machhalee” mean?

A: “Machhalee” is a Hindi word for “fish.”

Q: How did you come up with the idea?

A: My family and I regularly travel to India usually every 2-3 years, so for me the sight of fish vendors on street corners and at local marketplaces was a common and familiar sight, as it is to native Indians. However it always occurred to me the huge contrast between our experience in places like the UK of buying fish in comparison to theirs. Often their platform was very makeshift, working from the ground unprotected in the baking hot sun and with little to no ice. Generally poor quality.

In conjunction for my dissertation I gained a deeper insight into what I wanted to do for my final project, when I began tackling issues between wealth divides and how this affects the designs that we consume and use. Inspired by the works of Victor Papanek and Emily Pilloton of designing for social change, I decided that for this project I wanted to design something for those less well off in developing countries, those who were in true need of good design. However it was important for me that I didn’t want to create a product that revolved around aid. This was about empowerment and strengthening honest business, more importantly I wanted to create a product from the people and for the people.

Q: Did you talk with fish vendors as part of your research?

A: While I wasn’t able to talk directly to fish vendors in India due to the disconnect, I came pretty close. It was important that I design honestly and according to the needs of the vendors. I enlisted the help of many NGOs including the likes of the Selco Foundation in India as well as the National Association of Street Vendors of India, two huge players in my research. With their help I was able to identify all the key needs, patterns and processes in order to create the most appropriate design.

Q: How did you hear about phase change material?

A: One of my visiting lecturers, Ian Hunter from Material Council, mentioned its usage in cheap and effective cooling systems and so it piqued my interest. For a while we gained and lost interest in the idea while the designs developed before finally realizing it massive potential.

Q: How many PCM types did you try before settling on one?

A: I researched PCMs for a duration while doing the project. I moved from organic paraffin wax based ones to salt hydrates and so on. Ultimately I decided that using more environmentally friendly sources such as vegetable and animal fat PCMs would be better due to their stability, sustainability, re-use and wide temperature range. Also it occurred to me that it was possible for these PCMs to be locally manufactured and sourced by farmers, making it possible for them to benefit from the mix as well.

Q: Which PCM are you using and how is it contained?

A: After getting in contact with your associates at Entropy Solutions, I decided that PureTemp 8 from your range was the most appropriate due to it being agriculturally sourced and having a great heat storage capacity of 178J/g. It was also important that the PCMs be cooled passively at similar temperatures that ice are stored and manufactured in. In this case it was so that Ice vendors were still inclusive in process and could supply and recharge the PCM packs using their facilities at a fixed lease based price to the fish vendors. The fish vendors in turn would use the packs and return them in the evening for recharging, creating a harmonious cold chain.

A: After getting in contact with your associates at Entropy Solutions, I decided that PureTemp 8 from your range was the most appropriate due to it being agriculturally sourced and having a great heat storage capacity of 178J/g. It was also important that the PCMs be cooled passively at similar temperatures that ice are stored and manufactured in. In this case it was so that Ice vendors were still inclusive in process and could supply and recharge the PCM packs using their facilities at a fixed lease based price to the fish vendors. The fish vendors in turn would use the packs and return them in the evening for recharging, creating a harmonious cold chain.

I decided macroencapsulation was the best and most secure way to go using the plastic pouch method. On top of this the pouches [shown in yellow in cutaway drawing] would sit inside thin sheet metal aluminum containers, adding an extra layer of protection while still allowing for heat conduction.

Q: What if any insulation material is used in the cooler?

A: The majority of the insulation comes from the medium grade EPS that makes up the main body of the basket. This is a common and cheap material used in the fishing trade and so seemed appropriate. On top of this on the interior the fish sits inside a polyester tarpaulin bag and on the exterior the main body sits inside a secondary woven bamboo basket.

Q: How long did it take you to complete the project, from concept to prototype?

A: About 3½ months. It was part of our second semester and made up our final major project.

Q: What do you estimate the retail cost might be, when in full production?

A: I designed and planned the cooler in such a way for minimal cost with maximum effect. I truly made use of the fruits of India’s economy when considering how to do this. All materials are locally sourced and in abundance either by methods of cheap manufacture or locally available materials making it easy to repair and easy/cheap to replace.

On top of this I took into consideration the consumption styles of vendors and realized that what might work best was a lease-based platform. In this case the vendors could buy the basket outright for a small price and were given the opportunity to lease/purchase the PCM packs and display assembly if they required it. All costs considered, I estimate the vendors expenses would be no more than 20 rupees a week.

Q: Do you have plans to commercialize the cooler?

A: A few companies have shown interest in commercializing the cooler. However while it shows great promise and practicality, for now it is just a concept and has room for development and improvement, if it is to be successfully implemented. I believe in an open sourcing philosophy, especially when it comes to the potential for my target audience that it could help.

Q: What do you plan to do with the £500 prize?

A: I plan on using it to re-invest in my career, however I’m not sure entirely how. I might purchase a new laptop, or I could possibly use it for a plane ticket if the opportunity to take my work elsewhere calls!

PATENTS

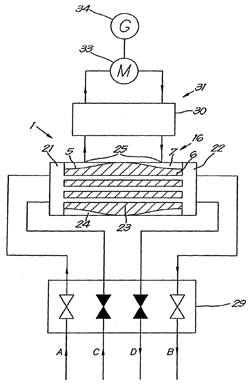

Energy cell for converting heat into other forms of energy

U.S. patent application 20170191469 (applicant Atlas Copco Airpower NV, Wilrijk, Belgium):

“An energy cell that is provided with a pressure vessel with two chambers separated by a membrane, respectively a first chamber filled with a phase-change material [23, at right] and a second chamber filled with hydraulic fluid, whereby this energy cell is provided with means to be able to heat and cool the phase-change material alternately, coupled with a volume change, whereby the second chamber is provided with a passage that acts as an input and/or output for the hydraulic fluid, whereby the membrane is stretched elastically upon a phase change whereby the volume in the first chamber increases.”

Technologies for releasing thermal energy

U.S. patent application 20170188754 (inventor Melissa Zimberg, Maplewood, N.J.):

“A heat unit containing a phase change material consisting of polyethylene glycol and a fatty acid combination of stearic and palmitic acids is disclosed. When heated in a microwave for about four (4) minutes the heat unit reaches a temperature of about 70° C. (158° F.). When placed in an insulated container, the heat unit will, after six (6) hours, have a temperature of about 40° C.-55° C. (104° F.-131° F.). The heat unit is advantageous for maintaining food hot during transport as well as other uses where long term heat emission is needed.”

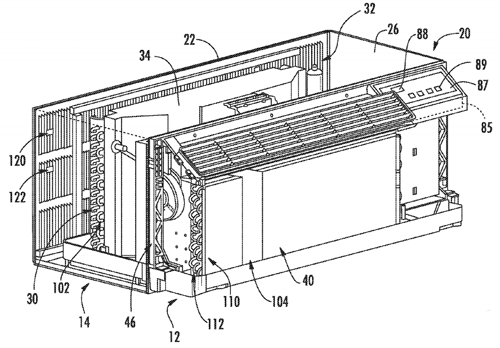

Air conditioner units having dehumidification features

U.S. patent application 20170191721 (applicant General Electric Co., Schenectady, N.Y.):

“Air conditioner units are provided. An air conditioner unit includes an outdoor heat exchanger, the outdoor heat exchanger including a coil assembly through which refrigerant is flowable, and an indoor heat exchanger, the indoor heat exchanger comprising a coil assembly through which refrigerant is flowable. The air conditioner unit further includes an auxiliary heat exchanger [110, above] disposed between the outdoor heat exchanger and the indoor heat exchanger along a refrigerant flow path, the auxiliary heat exchanger including a coil assembly [112] through which refrigerant is flowable and further including a phase change material.”

RESEARCH

Robot chemist shines in test against human counterparts

A University of Glasgow team has developed a robot equipped with an algorithm that allows it to be more efficient than human chemists in some applications. The robot isn’t likely to replace humans any time soon, Chemistry World reports, but it proved to be very effective at discovering and crystallizing gigantic self-assembling molecules.

“The robot extends the intuition of the human,’ said Dr. Lee Cronin, who led the team. “The robot frees the human from bias because it has more time to do reactions that a human wouldn’t otherwise choose to do. If you’re given a random set of reactions, you use your bias – or your training – to choose those reactions.”

IN BRIEF

• Abstracts are due July 14 for the 19th International Conference on Heat and Thermal Energy, to be held in London Sept. 20-21. Conference topics include novel storage concepts; thermal energy storage in buildings; thermal energy storage materials; polymeric materials; and micro- and macro-encapsulation methods. Researchers from Lucerne University of Applied Sciences and Arts will present their findings on “Unbranched, Saturated, Carboxylic Esters as Phase Change Materials.”

• From Chem.Info: “How Much Will Chemical Industry Employment Grow By 2019?”

• A mattress powered by Zotto‘s “ThermaPhase technology” is one of eight products on Forbes magazine’s “Must Have Summer Tech Gift Guide.”

• Unrelated link of the week, from Bored Panda: “Architect Turns Old Cement Factory Into His Home, And The Interior Will Take Your Breath Away”

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Journal of Industrial and Engineering Chemistry:• Performance evaluation of macro-packed fatty acid ester composites using energy-efficient thermal storage systems

From Procedia Manufacturing:

• Selective Laser Sintering of Phase Change Materials for Thermal Energy Storage Applications

From Applied Energy:

• Synthesis and characterization of microencapsulated myristic acid–palmitic acid eutectic mixture as phase change material for thermal energy storage

• Advances in thermal energy storage materials and their applications towards zero energy buildings: A critical review

From Solar Energy Materials and Solar Cells:

• A new strategy for enhanced latent heat energy storage with microencapsulated phase change material saturated in metal foam

• Preparation and characterization of hybrid nanocomposite embedded organic methyl ester as phase change material

From Renewable Energy:

• Cutting copper fiber/paraffin composite phase change material discharging experimental study based on heat dissipation capability of Li-ion battery

From Lehigh University:

• Numerical and Experimental Study of the Melting Process of a Phase Change Material in a Partically Filled Spherical Shell [thesis]

From IEEE Internet Computing:

• Thermal Time Shifting: Decreasing Datacenter Cooling Costs with Phase Change Materials

From International Journal of Heat and Mass Transfer:

• Numerical modeling of solid-liquid phase change in a closed 2D cavity with density change, elastic wall and natural convection

From Applied Thermal Engineering:

• Evaluation of the suitability of different calorimetric methods to determine the enthalpy-temperature curve of granular PCM composites

• Heat Transfer Enhancement during Freezing Process of Nano Phase Change Material (NPCM) In a Spherical Capsule

• Numerical simulation on thermal characteristics of supercooled salt hydrate PCM for energy storage: Multiphase model

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,100 of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members include Kalyani Orpe, chemical industry manager, MNM Group Inc., Mumbai, India; Ray Luke, inventor and founder at Solar Ready Ltd., Berkshire, U.K.; Karl Magnus Dahlberg, transport packaging R&D, Oslo, Norway; and Hassan Nazir, graduate student at Arizona State University.

You are invited to join the group and connect with PCM and TES experts from around the world. New members include Kalyani Orpe, chemical industry manager, MNM Group Inc., Mumbai, India; Ray Luke, inventor and founder at Solar Ready Ltd., Berkshire, U.K.; Karl Magnus Dahlberg, transport packaging R&D, Oslo, Norway; and Hassan Nazir, graduate student at Arizona State University.