The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

ENCAPSULATION

Fluorination process enhances barrier properties of HDPE

High-density polyethylene (HDPE) is a popular choice for containment of paraffin- and plant-oil-based phase change material. But under some conditions, PCM-filled HDPE containers are vulnerable to leaching.

Inhance Technologies of Houston has developed a process called ColdShield to enhance HDPE’s barrier properties. In an email interview, Prakash Iyer, senior vice president of business development and technology at Inhance, answered questions about the process.

Inhance Technologies of Houston has developed a process called ColdShield to enhance HDPE’s barrier properties. In an email interview, Prakash Iyer, senior vice president of business development and technology at Inhance, answered questions about the process.

Q: How does ColdShield work?

A: “HDPE is not stable when exposed to organic solvents such as paraffins and plant oils. Many PCM formulations are organic in nature and will readily permeate through HDPE, causing contamination of the surroundings and irreversible damage to the contents being transported. Inhance, through the use of its proprietary barrier treatment process, developed ColdShield technology to specifically prevent permeation of paraffin and plant oil based phase change materials.

“ColdShield provides a double barrier layer by protecting the inside and outside wall of the PCM container. The technology converts the surface of ordinary HDPE into a high-performance barrier material which repels paraffins and plant oils. The surface of HDPE is converted into a ‘PTFE’ like material with excellent barrier properties. By keeping the PCM formulation in the bottle from permeating, Inhance’s ColdShield prevents temperature drifts of the packaging due to selective absorption of the PCM formulation into the bottle walls. In addition, due to its superior barrier protection, ColdShield allows reuse of the PCM containers for many years with minimal to no reconditioning.”

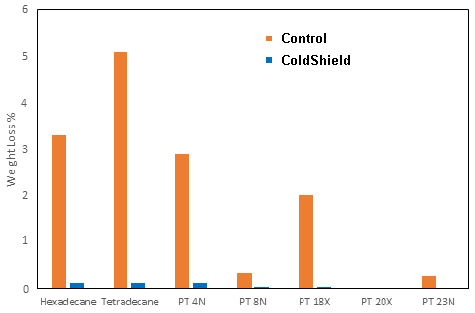

Q: Inhance tested five PureTemp formulations in ColdShield-enhanced HDPE containers. Describe the results.

A: “Inhance tested PureTemp 4N, PureTemp 8N, PureTemp 18X, PureTemp 20X and PureTemp 23N to study how these PCM formulations permeated through HDPE containers. Testing for permeation was done at 50° over 28 days, which would roughly equate to a two-year shelf life. All PureTemp PCM formulations, except for PT20X, showed varying amounts of permeation (ranging from 0.25-3% weight loss) through HDPE. The same PCM formulations when tested in ColdShield-treated HDPE containers exhibited less than 0.1% permeation weight loss. In addition to PureTemp formulations, Inhance also tested hexadecane and tetradecane, which are commonly used in PCM formulations. The permeation rates of hexadecane and tetradecane without barrier protection are 3-5%, while ColdShield reduces this to 0.1%. The chart below reflects the data.”

Q: How do you test ColdShield-treated containers for leaching?

A: “One of the simplest tests to evaluate for leaching is to do a weight-loss test on HDPE containers filled with these PCM formulations. Testing can be done at different temperatures for varying amounts of time. 49CFR.173 Appendix B, describes the commonly used test procedure to evaluate for permeation of liquids in plastic packaging, and is generally done at 18°C for 180 days, or 50°C for 28 days, or 60°C for 14 days. Per the U.S. Department of Transportation, the maximum permissible permeation rate for the above testing conditions should not be greater than 2% for nonpoisonous liquids.”

Q: Are ColdShield-enhanced HDPE containers now being produced commercially for any PCM manufacturers?

A: “ColdShield-enhanced HDPE containers are being commercially used by some of the largest manufacturers of PCM formulations as well as OEMs involved in the cold chain logistics chain.”

Q: On a percentage basis, how much does the ColdShield process add to the cost of an HDPE container?

A: “The cost of ColdShield is minimal compared to the value that it brings to the OEMs. The permeation of PCM into the package can result in costly recalls and contamination issues. Cold chain is used to often transport vaccines, biologics and organs across the globe and the loss/contamination of these contents can run into the millions. ColdShield provides the best barrier solution for HDPE rigid gel packs, thereby maintaining the PCM composition, while providing safe storage during transportation.”

Q: Has research on ColdShield performance been published?

A: “ColdShield brochures are available on www.inhanceproducts.com. For further information contact info@inhanceproducts.com. Inhance is glad to partner with companies to educate them on the advantages of ColdShield and works closely with its customers to provide the optimum solution. Inhance also has test capabilities to carry our permeation testing as well as other fitness testing of different PCM formulations.”

Q: Has the effect on heat transfer or other PCM performance characteristics been tested? How about the effect of, say, thousands of freeze/melt cycles on barrier properties?

A: “Inhance’s ColdShield technology has been tested and approved by OEMs and molders through stringent testing, including, but not limited to, permeation, freeze/melt cycles as well as mechanical testing. Since ColdShield is not a coating – ColdShield chemically transforms the surfaces of containers into a material that is resistant to solvents – there is no cracking or peeling of the barrier layer. In addition, since ColdShield does not change the bulk properties of the rigid gel pack, there is no change in the heat transfer profile. In addition, ColdShield provides a double layer of protection since the inside and the outside of the container is protected equally.”

PATENTS

Capsules having surfactant tethered outer shells

U.S. patent application 20180009996 (applicant Microtek Laboratories Inc., Dayton, Ohio):

“Microcapsules are disclosed that have a core composition encapsulated within a polymer wall, and an inorganic shell connected to an exterior surface of the polymer wall by a surfactant. The inorganic shell has a cation attracted to the surfactant and an anion or anion equivalent chemically bonded to the cation to form the shell or has the metal portion of a metal-containing compound attracted to the surfactant to form the shell. The shell may comprise a Ca, Mg, or Ag metal compound. The shell may be a graphene oxide-metal compound.”

Encapsulated PCM and thermal battery

U.S. patent application 20180010862 (Valeo Systemes Thermiques, Le Mesnil Saint-Denis, France):

“The present invention relates to an encapsulated phase-change material comprising a phase-change material (3) contained within a tube (5), said tube being made of plastic and that it has a sealing weld (9) at least at one of its ends. … The presence of sealing welds allows good sealing and also reduces the risk of leakage of phase-change material notably when the latter is in the liquid phase.”

“The present invention relates to an encapsulated phase-change material comprising a phase-change material (3) contained within a tube (5), said tube being made of plastic and that it has a sealing weld (9) at least at one of its ends. … The presence of sealing welds allows good sealing and also reduces the risk of leakage of phase-change material notably when the latter is in the liquid phase.”

Heating water with refrigerant and PCM

U.S. patent application 20180010822 (applicant Rheem Manufacturing Co., Atlanta, Ga.):

“An apparatus for heating water has a tank for storing water and an air conditioning system that defines a refrigerant flow path through which refrigerant flows. The refrigerant flow path passes through a heat exchanger so that refrigerant heat is contributed to the tank. The heat exchanger houses a phase change material. A controller controls operation of the water heating apparatus.”

IN BRIEF

• Cleanergy AB of Sweden and the Moroccan Agency for Sustainable Energy have agreed on a framework to jointly develop a thermal energy storage system using Cleanergy’s Stirling-based solar electricity technology.

• Applications are being accepted for the World Materials Forum Startup Challenge. Companies with fewer than 50 employees are eligible for the competition, which recognizes technical or organizational breakthroughs in one of five categories, including materials composition, product design and 3D manufacturing. The winning company will receive a 50,000 euro award at the World Materials Forum in June in Nancy, France.

• Grace Hsia, co-founder and CEO of Warmilu LLC, is among 14 entrepreneurs in the running for the $1 million top prize in the WeWork Creator Awards Global competition. The winner will be announced in New York City on Jan. 17.

• Prize money totaling 52,500 euros, financed by Germany’s National Climate Initiative, is up for grabs in the German Refrigeration Prize 2018 competition, honoring innovations in air conditioning and refrigeration. The entry deadline is Jan. 31. Winners will be announced at the Berlin Energy Days conference in May.

• SpaceX is seeking candidates for the position of thermal engineer.

• Pacific Gas & Electric will introduce a new electric time-of-use rate in April. The California utility says the optional rate will make energy use more efficient and minimize peak demand challenges. The peak pricing will be from 4 p.m. to 9 p.m.

• Bain & Co. has analyzed how chemical companies can “demystify” the R&D process. Among the three common “failure modes” Bain identified: “strong team running in too many directions.”

• Buro Happold associate Mark Dowson will speak on the topic of “phase change materials for ultimate thermal efficiency” at the 2018 Materials for Architecture conference in London in April.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Applied Thermal Engineering:• Guidelines for the specification of a PCM layer in Firefighting Protective Clothing Ensembles

From Advances in Mechanical Engineering:

• Thermal storage/management system with phase change materials for building

From International Journal of Renewable Energy Technology:

• An experimental investigation of PCM based thermal energy storage system using diesel engine exhaust-gas

• Numerical investigation on cooling behaviour of buildings using phase change material

From Energy Procedia:

• Non-eutectic Phase Change Materials for Cold Thermal Energy Storage

• Effects of void spaces in a phase change material based thermal energy storage system

• Preparation and Performance of Composite Building Materials with Phase Change Material for Thermal Storage

• Environmental performance assessment of the application of high temperature phase change materials in waste-to-energy plants

From Construction and Building Materials:

• Preparation and properties of fatty acids based thermal energy storage aggregate concrete

From International Journal of Heat and Mass Transfer:

• Optimizing fin design for a PCM-based thermal storage device using dynamic Kriging

From Energy Conversion and Management:

• A new approach using un-encapsulated discrete PCM chunks to augment the applicability of solid gallium as phase change material in thermal management applications

• Adjustment of thermal behavior by changing the shape of PCM inclusions in concrete blocks

From Applied Energy:

• Characterization of microencapsulated and impregnated porous host materials based on calcium chloride for thermochemical energy storage

• Performance comparison of latent heat storage systems comprising plate fins with different shell and tube configurations

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,100 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members include Marc Flender, renewable energy consulting engineer, Nantes, France; Loic de Francqueville, senior engineer, Hutchinson S.A., Châlette-sur-Loing, France; Mark Gilbert, quality assurance administrator at va-Q-tec Ltd., Rochester, U.K.; Andrés Gallardo Ocampo, technical analyst at Instituto Nacional de Eficiencia Energética y Energías Renovables, Quito, Ecuador; and Soumalya Chakraborty, research analyst at Global Market Insights Inc., Pune, India.

You are invited to join the group and connect with PCM and TES experts from around the world. New members include Marc Flender, renewable energy consulting engineer, Nantes, France; Loic de Francqueville, senior engineer, Hutchinson S.A., Châlette-sur-Loing, France; Mark Gilbert, quality assurance administrator at va-Q-tec Ltd., Rochester, U.K.; Andrés Gallardo Ocampo, technical analyst at Instituto Nacional de Eficiencia Energética y Energías Renovables, Quito, Ecuador; and Soumalya Chakraborty, research analyst at Global Market Insights Inc., Pune, India.