The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

MEDICAL

PCM-equipped infant warming mat set for large-scale trial in Rwanda

An infant warming mat developed at Lawrence Berkeley National Laboratory in California has been approved for a six-month trial at 10 hospitals in Rwanda beginning next fall. The DREAM infant warmer uses biobased phase change material to keep newborns warm in places where electricity is unavailable or unreliable. Dr. Anne Hansen, medical director of the neonatal intensive care unit at Boston Children’s Hospital, helped develop the mat and is directing the trial. In an interview, she provided background on the device and explained how it works.

An infant warming mat developed at Lawrence Berkeley National Laboratory in California has been approved for a six-month trial at 10 hospitals in Rwanda beginning next fall. The DREAM infant warmer uses biobased phase change material to keep newborns warm in places where electricity is unavailable or unreliable. Dr. Anne Hansen, medical director of the neonatal intensive care unit at Boston Children’s Hospital, helped develop the mat and is directing the trial. In an interview, she provided background on the device and explained how it works.

Q: Tell me about the need for this device. What problem does it solve?

A: In low- and middle-income countries, hypothermia is a contributing cause in about one million infant deaths per year. It’s pretty rare for a baby to die only of hypothermia, but what happens is when you’re hypothermic, as a newborn, then a lot of other problems start to accrue, related to breathing, glucose regulation, infection prevention, how well your immune system works, how well you grow, how well your brain grows, and therefore your ultimate neuro-developmental outcome. Newborn babies, especially babies who are low birth weight or preterm or both, tend to cool to the temperature of their environment.

Q: Why is this a particular problem for babies born in lower-income countries?

A: If they’re born in a rich country, there’s this kind of heat chain that protects them all the way from the delivery room until they go home from the hospital, which consists of things like warming tables and incubators. In poor countries, where there’s an inconsistent supply of electricity or there’s no electricity, and also where people can’t afford expensive warmers and incubators and where they don’t have biomedical supply staff to maintain the warmers, they try to do all kinds of workarounds. The World Health Organization recommends skin-to-skin care, where you put a newborn directly on the mother’s skin and that’s the external heat source. Skin-to-skin is great; we are total fans of skin-to-skin. The problem is that there are times where it’s not very feasible, when the mother is sick or the mother dies in childbirth or if she has twins or triplets, the baby is sick and requires medical assessments and treatments.

Then, most importantly, it’s hard to be a human incubator for weeks to even months to let these preterm babies get old enough and mature enough to not need this external heat source. So doing continuous skin-to-skin just really round the clock, all day, all night for a long time, mothers just can’t do that. They need to bathe, they need to cook over a fire, they need to take care of their other children. So they obviously just have to stop and they put the kids down in a regular bed and then they get really cold.

The other thing is that for the littlest babies it’s not actually enough heat source, so they’re just getting heat from the front of the mother’s chest, but they aren’t getting any heat on the back of themselves. So we were looking to make something that would be both a complement to skin-to-skin care when mothers want to put the baby down, and also that could be additive to skin-to-skin care when it’s not enough heat.

We were looking for something that was inexpensive, very intuitive to use, required minimal training, can be reused a thousand times and does not require electricity.

Q: What was your role in the development of the device?

A: I’ve been working with a group called Partners in Health in Rwanda for about 10 years, and they work in very close collaboration with the Rwandan Ministry of Health. When I first went there in 2010, we helped them to develop and implement a national standard for newborn medicine, and one of the things that was very clear was that the methods for thermoregulation were not working. So when I came back I partnered with Lawrence Berkeley Lab to think about some other alternatives. We looked at a lot of things, we looked at solar, we looked at a whole bunch of different things and came up with this phase change approach because it’s so simple and straightforward and easy.

The engineers did the actual design work, but we worked hand in glove with them over many years to fine-tune it, figure out how long it needed to be, how heavy it could be, how much people were willing to pay for it. For example, we are using a sort of wide-based thermos to hold boiling water to melt the PCM. The Ministry of Health was very interested in making sure that the thermos was safe and not dangerous and wouldn’t tip over when it was being filled with the boiling water.

The engineers did the actual design work, but we worked hand in glove with them over many years to fine-tune it, figure out how long it needed to be, how heavy it could be, how much people were willing to pay for it. For example, we are using a sort of wide-based thermos to hold boiling water to melt the PCM. The Ministry of Health was very interested in making sure that the thermos was safe and not dangerous and wouldn’t tip over when it was being filled with the boiling water.

Then I’ve done two clinical studies of it in Rwanda and just gearing up to do what I hope will be a definitive final, huge study with 10 hospitals in Rwanda this year. The Rwandan Ministry of Health has been amazing through all of this, supporting all of our studies and helping facilitate. We’re getting approval through the Rwandan Standards Bureau, which is like their FDA for the device, and also they are going to sponsor having the device approved as an actual international approval process that at least across Africa is widely accepted as a way of approving devices. We’re going to wait to do that until after this big, randomized control trial that we’ll be doing this coming year.

Q: Describe how the device functions.

A: We use your phase change material, PureTemp 37, contained in a series of … you can think of them as candles that are each in their own plastic sleeve. Each pad measures about 45.7 cm, by 25.4 cm, by 1.91 cm thick and contains about 100 grams of PCM. The configuration allows the mat to be rolled up for charging or storage. … Boiling water is used to charge the mat. All human civilizations know how to heat water, so whether it’s coal or if you do have electricity, you heat 1.7 liters of water to boiling temperature, which provides the exact amount of energy that you need to melt all the wax. The mat has a little color temperature indicator. You wait until the color indicator shows that it’s a safe temperature, you dry it off, you slip it in a little insulating pad. Then you put the baby, ideally naked, on the pad. This tends to be a population that does not have diapers, so that was actually a key piece in designing it to not have any fabric or any Velcro or anything that couldn’t easily be cleaned. So baby goes naked on the warmer and then you put a hat on the baby and socks if you’ve got them, and then you wrap the baby and the warmer up in a blanket. The warmer stays hot for up to six hours, exactly at skin temperature.

A: We use your phase change material, PureTemp 37, contained in a series of … you can think of them as candles that are each in their own plastic sleeve. Each pad measures about 45.7 cm, by 25.4 cm, by 1.91 cm thick and contains about 100 grams of PCM. The configuration allows the mat to be rolled up for charging or storage. … Boiling water is used to charge the mat. All human civilizations know how to heat water, so whether it’s coal or if you do have electricity, you heat 1.7 liters of water to boiling temperature, which provides the exact amount of energy that you need to melt all the wax. The mat has a little color temperature indicator. You wait until the color indicator shows that it’s a safe temperature, you dry it off, you slip it in a little insulating pad. Then you put the baby, ideally naked, on the pad. This tends to be a population that does not have diapers, so that was actually a key piece in designing it to not have any fabric or any Velcro or anything that couldn’t easily be cleaned. So baby goes naked on the warmer and then you put a hat on the baby and socks if you’ve got them, and then you wrap the baby and the warmer up in a blanket. The warmer stays hot for up to six hours, exactly at skin temperature.

Q: What’s the projected price for a single unit?

A: Our goal is to make sure it’s well under $100.

Q: Tell me about the upcoming study.

A: We’re going to start this study in September and run it for six months. It’s a very complex study design to meet the ethical standard of not having one baby who’s cold who gets a warmer and another baby in the next bed who’s cold who doesn’t get a warmer. So we’re doing pre-data and post-data, with the intervention in the middle so that it is ethically acceptable, and so it will take us six months to do this whole step wedge, complex WHO biostatistical design. Then we need to analyze that and then we’ll be moving to full-scale production. So I am hoping that by some time in 2020 we are actually making these and turning them out and trying to get them all over sub-Saharan Africa.

Q: Where does the mat stand as far as approval processes in Africa?

A: We are still really at the prototype phase. We met this summer with a representative of the Rwandan Standards Bureau. He said that as far as he’s concerned, based on the results of our two preliminary pilot studies, we’ve got 204 uses now, that they are happy to go ahead and accept the paperwork to approve it, but we have not done that yet only because they want it to be the absolutely final design that they are approving and we are still doing a little bit more work with, as we were just discussing, which plastic we’re using, and also we’re going to change out the color indicator. We currently have a color indicator that’s not very robust and lasts about 40 uses and it’s actually kind of expensive, and so we’re going to use a different color indicator. Once we have all that final work then we will submit the paperwork and it will go through the Ministry of Health, into the Rwandan Standards Bureau, but the person we met with said that they’ll be very excited to approve it.

Q: What’s been the most satisfying part of this project for you?

A: That is so easy. It is absolutely 100 percent the mothers. The very first patient that we enrolled, it was a mom who had twins. When we walked into the hospital it was the very first day we had just explained to the nurses how to prepare the warmer, we were going to enroll our first patients, and there was this mother with these twins and she looked so depressed and it was so … She just looked so exhausted and through a translator I asked her if she would be willing to be our very first mother and babies enrolled in this study, she learned what it was, she said that she consented.

We took the babies, one of them actually was so cold that we did the combination of the skin-to-skin and warmer across the back, and then one of them was just the baby straight on the warmer, and then she looked at them and she saw them getting warm. She just had this unbelievable look of relaxation on her face and her shoulders, and she was so happy. She said, “This is the first time that I’ve seen my babies look comfortable since they were born.”

PATENTS

Inverse latent heat thermal energy storage system

U.S. patent application 20190003782 (applicant UChicago Argonne LLC, Chicago, Ill.):

U.S. patent application 20190003782 (applicant UChicago Argonne LLC, Chicago, Ill.):

“The invention provides a method for storing and releasing heat having the steps of thermally contacting thermal transfer fluid to a mixture of foam and phase change material for a time sufficient for the material to change from a first phase to a second phase during a time when electricity rates are at a first price point; maintaining said material in the second phase until electricity rates are at a second point, wherein the second point is higher than the first price point; and thermally contacting the thermal transfer fluid to the composite in the second phase for a time sufficient for the material to change from the second phase to the first phase. The invention also provides an energy storage module having a mixture of phase change material and high surface area substrate.”

Fibrous structures comprising phase change materials

U.S. patent application 20190002747 (applicant Procter & Gamble Co., Cincinnati, Ohio):

“Fibrous structures, for example sanitary tissue products, such as toilet tissue, having one or more neat, endothermic phase change materials on at least one exterior surface, methods for making same, and methods for eliciting a sensation on a user’s skin are provided. … The fibrous structure according to claim 1 wherein the neat, endothermic phase change material is selected from the group consisting of: hydrocarbons, waxes, oils, natural butters, fatty acids, fatty acid esters, dibasic acids, dibasic esters, 1-halides, primary alcohols, aromatic compounds, anhydrides, ethylene carbonates, polyhydric alcohols, and mixtures thereof.”

Thermal storage system and temperature controlled container

U.S. patent application 20190003781 (applicants University of Ghent, Belgium; Colruyt Group, Halle, Belgium):

“Passive thermal storage systems and methods comprising at least one thermal storage module for storing thermal energy in a predetermined temperature range, are disclosed. The thermal storage module comprises an FT unit and a Heat Storage (HS) unit at least partially filled with a first Phase Change Material (PCM). The HS unit comprises a container. The thermal storage module may be in the form of a stacked structure comprising the FT unit having a first wall with a first heat exchange surface and the HS unit having a second wall with a second heat exchange surface, the first and second heat exchange surfaces being in thermal contact with each other. The thermal storage system may be used to maintain the temperature of the payload of a temperature controlled container at a predetermined value or within a predetermined range.”

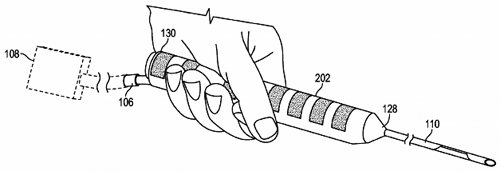

Surgical instrument with phase change cooling

U.S. patent application 20180375402 (applicant Covidien LP, Mansfield, Mass.):

“Systems and methods are discussed herein for cooling a surgical handset using a phase-change material. A container filled with a phase-change material may be telescoped over a heat-generating mechanism of a surgical handset, such as a battery and/or a motor. When the surgical handset is activated, the heat generated by the heat-generating mechanism is absorbed by the phase-change material in the container, which transitions from a first phase to a second phase.”

IN BRIEF

• The University of Birmingham‘s Center for Energy Storage has teamed up with a Chinese railway equipment manufacturer to develop a shipping container that uses phase change materials to maintain a low temperature over several days without a power supply. “Once ‘charged’, PCM inside the container – which can be transferred from train to truck and vice versa – can keep the inside temperature between 5-12 ˚C for up to 120 hours,” the university reports.

• CNET‘s Scott Stein takes a close look at PowerStation, “a battery of sorts that can keep a low-power sensor running off the temperature differences in everyday weather conditions.” The device, made by Matrix Industries of Menlo Park, Calif., stores heat in a substance the company calls “Luna Phase Change Material” and later releases the heat in the form of electricity.

• Scottish Business Insider has named Sunamp Ltd. one of five Scottish tech companies to watch in 2019. “The £2.2m raised in its latest fundraising sets the company up for a Series A round in 2019 as it looks to expand its international footprint and further scale its operations,” Insider writes. “Sunamp heat batteries have so far been installed in over a thousand homes across the UK.”

• C-Therm managing director Adam Harris is hosting a webinar next week to introduce the company’s new thermal conductivity instrument, the C-Therm Trident. Advance registration is required for the webinar, which will be held at 1 p.m. EST Thursday, Jan. 10.

• At a business summit in Wisconsin last month, Encapsys President Mary Goggans said the Appleton-based company offers internships to students at regional colleges, including the children of employees. “The interns see the jobs and technologies they are interested in right here in the area,” Goggans said. “They realize they don’t need to get a job outside of the region to have the career they are looking for.”

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Industrial & Engineering Chemistry Research:• Development of Phase-Change-Based Thermally Modulated Fiber Sorbents

From ChemistrySelect:

• Preparation and Thermal Properties of 1‐Hexadecanol‐Palmitic Acid Eutectic Mixture/Activated Carbon Composite Phase Change Material for Thermal Energy Storage

From Energies:

• Thermal Conductivity Enhancement of Phase Change Materials for Low-Temperature Thermal Energy Storage Applications [pdf]

• Metamaterial-Based Radiative Cooling: Towards Energy-Free All-Day Cooling [pdf]

From Renewable and Sustainable Energy Reviews:

• A review and evaluation of thermal insulation materials and methods for thermal energy storage systems

From Materials Letters:

• Stearic–capric acid/porous nanoceramics as a novel form-stable composite phase change material (FSPCM) for thermal energy storage

From International Refrigeration and Air Conditioning Conference:

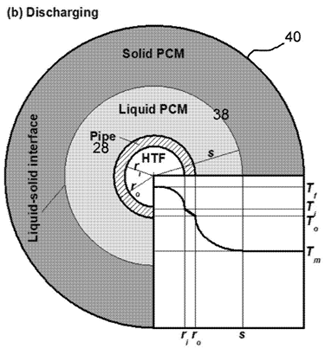

• Analysis of TES with PCM (Solid/Liquid) Integrated in a Residential System

• Experimental Study on Portable Air-Conditioning System with Enhanced PCM Condenser

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,400 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,400 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This month we welcome Farzad Jafarkazemi, managing director at Mehrtab Energy Co. Ltd., Iran; Yann Largouet, development manager at Axima Refrigeration France; Timothy Wirzburger, account manager at Web Canopy Studio, Traverse City, Mich.; Manish Naik, co-founder at Opti Engineering, Vadodara, India; and Elmar Asgarzada, chemical engineering student at Baku Higher Oil School, Azerbaijan.