The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

ENERGY STORAGE

Dutch-led consortium develops calculation model for industrial heat storage

A consortium led by the Energy Research Center of the Netherlands (ECN) has developed a calculation model to predict the performance of a phase change material buffer for industrial heat storage in the 100-250° C temperature range. The model is used to optimize the design of a heat exchanger to achieve the required performance in the most cost-effective way. According to the ECN:

A consortium led by the Energy Research Center of the Netherlands (ECN) has developed a calculation model to predict the performance of a phase change material buffer for industrial heat storage in the 100-250° C temperature range. The model is used to optimize the design of a heat exchanger to achieve the required performance in the most cost-effective way. According to the ECN:

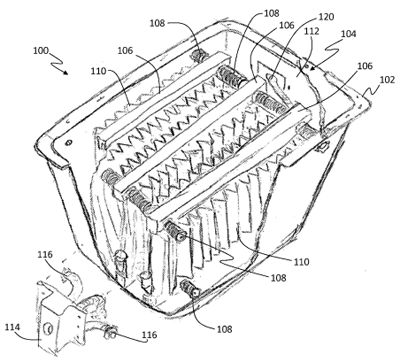

“A test installation with around 100 liters of PCM (see photo) is used to measure the performance of the storage and compare it with the model calculations. There is a high level of consistency between the experimental and model outcomes, providing a basis for the further development and scaling of PCM heat storage technology.”

The consortium continues to work on the selection of PCMs with the desired attributes for industrial heat storage.

“We consider salt hydrates as most feasible option for industrial heat storage,” said Robert de Boer, thermal systems project manager at ECN. “I wouldn’t say it is ideal, but the best we can get at this moment.”

Members of the LOCOSTO consortium are end-users DOW, Perstorp and EMMTEC; system suppliers IEE and Bronswerk Heat Transfer; materials suppliers PCM Technology and Nedmag; and Dutch research institutes TNO and ECN. “LOCOSTO” stands for “LOw COst STOrage” of heat.

IN BRIEF

• Dr. Britta Nestler of the Karlsruhe Institute of Technology has won the 2017 Gottfried Wilhelm Leibniz Prize for her research into computer-aided materials modeling. The prize comes with $2.6 million in research funds to be used at her discretion. Her work includes the development of foam structures within integrated phase change materials for use in latent heat storage systems.

• Dr. Britta Nestler of the Karlsruhe Institute of Technology has won the 2017 Gottfried Wilhelm Leibniz Prize for her research into computer-aided materials modeling. The prize comes with $2.6 million in research funds to be used at her discretion. Her work includes the development of foam structures within integrated phase change materials for use in latent heat storage systems.

• The 2017 outlook for the U.S. chemical industry is better than that in Germany and Europe, the American Chemistry Council reports. The U.S. industry group expects a 3.6 percent production increase, compared with the 0.5% increase expected by the European Chemical Industry Council.

• Alexium International, maker of Alexicool phase change material, has an opening for a senior sales rep at its office in Greer, S.C.

• Setaram Instrumentation‘s next free webinar, “Thermal Analysis and Calorimetry Applied to Thermal Energy Storage,” will be held Jan. 24, 2017.

• New from QY Research: “United States Microencapsulated Phase Change Materials (MPCM) Market Report 2016“

• Thermal Analysis Labs is offering a free webinar on characterizing the thermal conductivity of phase change materials and heat transfer fluids. The webinar will be held at 1 p.m. EST Dec. 20.

• Ember Technologies, maker of the Ember temperature-adjustable mug on sale at Starbucks and online, says it has secured $8.5 million in investor funding to date. The Ember mug uses phase change material and a microprocessor-controlled heating system to maintain hot beverages at temperatures set by the user. Celebrity investors include singer-songwriter Demi Lovato, NFL star Ndamukong Suh and retired MLB pitcher Ted Lilly. The mug landed a spot on Popular Science magazine’s list of the year’s 100 greatest new innovations in science and technology.

• Va-Q-tec AG has signed a deal to supply Swiss Post with a fleet of temperature-controlled shippers. The shippers will be used for distribution of pharmaceutical products in the 15º C to 25º C range.

• A U.S. science and technology think tank urges the Department of Energy to focus on “advanced cooling and thermal energy storage” and other renewable technologies to help the United States retake the lead in the global clean-energy technology market. In a new report, the Information Technology and Innovation Foundation says U.S. federal funding for energy research and development lags behind 11 other countries as a percentage of gross domestic product.

• SunAmp Ltd.‘s heat storage battery is among the energy-efficient technologies used in what are being marketed as Scotland’s most eco-friendly homes. The four four-bedroom detached homes in Dalkeith feature rooftop solar panels, triple-glazed windows and 8.5 inches of insulation surrounding all sides, with 7 inches under the floor and 21 inches in the roof. Developers project energy bills of less than $40 a month.

PATENTS

Passive temperature controlled container

U.S. patent application 20160362240 (applicant Inmark Global Holdings, Austell, Georgia):

U.S. patent application 20160362240 (applicant Inmark Global Holdings, Austell, Georgia):

“The disclosed technology includes a passive temperature controlled container for passively maintaining a specified temperature range in a storage chamber of the container for a predetermined amount of time. The passive temperature controlled container may be configured to have an inner PCM layer and an outer PCM layer, with an air chamber layer between the two PCM layers to allow for the free movement of air around all six sides of the container. …

“According to some embodiments, an inner PCM layer may include an inner PCM material with a phasing temperature of 4° C. that can serve to maintain the temperature of the storage chamber at a desired temperature range of 2° C-8° C. In some embodiments, an inner PCM may have a phasing temperature of between 2° C-8° C. In some embodiments, an inner PCM may have a phasing temperature of between 15° C-25° C. It should be understood that a wide variety of different PCM materials having different phasing temperatures can be used in both the inner PCM layer and the outer PCM layer to achieve a variety of desired temperature ranges.”

Phase change material heat exchanger

U.S. patent application 20160363387 (applicant Hamilton Sundstrand Space Systems International Inc. (Windsor Locks, Conn.):

U.S. patent application 20160363387 (applicant Hamilton Sundstrand Space Systems International Inc. (Windsor Locks, Conn.):

“A phase-change material heat exchanger includes a frame configured to define a chamber therein and house a first fluid, the first fluid being water. At least one heat exchange element is configured to have a second fluid pass through an interior of the heat exchange element, the at least one heat exchange element moveably retained within the chamber. When the second fluid passes through the heat exchange element at a first temperature, the first fluid changes from a liquid to a solid, and the second fluid exits the heat exchange element at a second temperature that is higher than the first temperature.”

Rootzone heating for energy conservation using latent heat storage

U.S. patent 9,510,515 (inventor Dr. William R. Sutterlin, Hoover, Ala.; assignee Entropy Solutions LLC, Plymouth, Minn.):

“A plant pot or a plant container comprising: a phase change material (PCM) or a composition comprising a PCM, wherein the plant pot or plant container is formed from or has as part of its structure or has as a structural component comprising the PCM or composition comprising the PCM, and a sufficient amount of PCM is provided in or part of the plant pot or plant container to maintain a root zone environment having a consistent temperature environment or optimal temperature environment for a plant’s root system growth or maintenance, and wherein the PCM or the composition comprising the PCM: (a) is positioned in as part of the plant pot or plant container to be approximate to, close to, in contact with, or substantially in contact with, the plant root system or a soil, or (b) is present as part of or as a structural component of the plant pot or plant container, in an amount sufficient to maintain a root zone environment having a consistent temperature environment or optimal temperature environment for the plant’s root system growth or maintenance.”

“A plant pot or a plant container comprising: a phase change material (PCM) or a composition comprising a PCM, wherein the plant pot or plant container is formed from or has as part of its structure or has as a structural component comprising the PCM or composition comprising the PCM, and a sufficient amount of PCM is provided in or part of the plant pot or plant container to maintain a root zone environment having a consistent temperature environment or optimal temperature environment for a plant’s root system growth or maintenance, and wherein the PCM or the composition comprising the PCM: (a) is positioned in as part of the plant pot or plant container to be approximate to, close to, in contact with, or substantially in contact with, the plant root system or a soil, or (b) is present as part of or as a structural component of the plant pot or plant container, in an amount sufficient to maintain a root zone environment having a consistent temperature environment or optimal temperature environment for the plant’s root system growth or maintenance.”

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Renewable and Sustainable Energy Reviews:• A review on supercooling of phase change materials in thermal energy storage systems

• Thermal conductivity enhancement of treated petroleum waxes, as phase change material, by α nano alumina: Energy storage

• A review on current status and challenges of inorganic phase change materials for thermal energy storage systems

From International Conference on Computational Modeling, Simulation and Applied Mathematics:

• Development of Phase Change Materials for Refrigerated Transportation of Fruits and Vegetables

From Science Bulletin:

• Numerical study on solid–liquid phase change in paraffin as phase change material for battery thermal management

From Energy Conversion and Management:

• Comparative study of two weir type cascade solar stills with and without PCM storage using energy and exergy analysis

From Applied Thermal Engineering:

• Numerical calibration and experimental validation of a PCM-air heat exchanger model

From Energies:

• Cold Storage for a Single-Family House in Italy

From Solar Energy Materials and Solar Cells:

• Thermal energy storage characteristics of poly(styrene-co-maleic anhydride)-graft-PEG as polymeric solid–solid phase change materials

From RSC Advances:

• Sepiolite supported stearic acid composites for thermal energy storage

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 980 of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Dr. Farhan Ahmad, senior innovation scientist at Amcor, Detroit; Luigi Mongibello, researcher at the Italian National Agency for New Technologies, Energy and Sustainable Economic Development, Naples, Italy; Kuan-Lin Lee, R&D engineer at Advanced Cooling Technologies Inc., Lancaster, Penn.; and Anurag Bansul, global business development at ACCIONA Infraestructuras S.A., Madrid, Spain. Anurag writes:

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Dr. Farhan Ahmad, senior innovation scientist at Amcor, Detroit; Luigi Mongibello, researcher at the Italian National Agency for New Technologies, Energy and Sustainable Economic Development, Naples, Italy; Kuan-Lin Lee, R&D engineer at Advanced Cooling Technologies Inc., Lancaster, Penn.; and Anurag Bansul, global business development at ACCIONA Infraestructuras S.A., Madrid, Spain. Anurag writes:

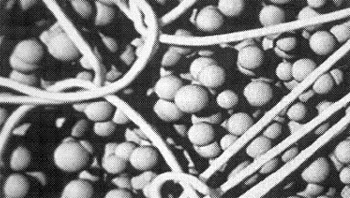

“I am working at the Technology and Innovation Division of ACCIONA Infraestructuras SA. Our research team has developed and patented the process of microencapsulation of phase change materials (EP 09153793). In case anybody is interested to have further information on it, do feel free to contact me.”