The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

NEW PRODUCTS

Ember temperature-control mug finally hits the market

Ember Technologies, which raised more than $360,000 on IndieGoGo last year, has finally released its flagship product, the temperature-controlled Ember mug.

The $149 mug is being delivered to nearly 2,000 IndieGoGo backers and is available for purchase at dozens of Starbucks outlets in the United States. The mug quickly sold out at starbucks.com (it’s back in stock today) and is on backorder on embertech.com, with delivery promised in January.

“The release of the Ember mug is seven years in the making. I started Ember to solve a simple yet universal challenge faced by coffee and tea drinkers everywhere — how can I keep my hot beverage at the ideal temperature for as long as I want,” Ember Technologies founder and CEO Clay Alexander said in a news release.

The Ember mug uses phase change material and a microprocessor-controlled heating system to maintain hot beverages at temperatures set by the user.

The Ember mug uses phase change material and a microprocessor-controlled heating system to maintain hot beverages at temperatures set by the user.

Hot beverages are usually served around 160° Fahrenheit — far too hot to drink. Which means coffee drinkers must typically wait for their java to cool to drinkable temperature, commonly 135°. That’s where Ember’s phase change cooling technology makes a big difference. The PCM in Ember’s lining absorbs the excess heat to rapidly cool the drink and then works in concert with a battery-powered heating element to keep the drink hot.

The Ember mug can maintain a temperature for about two hours on the go or indefinitely when on its slim charging coaster. A twist of the base adjusts the temperature. A mobile app allows users to set and select temperature profiles for coffee, tea or other beverages.

A few early reviews:

• “Beautiful packaging and works flawlessly. I also put in cold water and had it heat to 133. Very cool. Should have ordered an extra coaster.” — Christopher Hall, IndieGoGo backer

• “Wish I had another charger and vehicle charger. Two hours is not very long, especially for a second cup of coffee once in town or for the drive back home after shopping day is done. Another wish is that the cup made notification sounds or at least flash ‘ready,’ Different colors in the display would be great too. Lovin’ the temp stays hot!” — Heather Baker, IndieGoGo backer

• “Want it hotter or colder? Adjust the temp on the mug or in the app. Works amazing and holds temp for hours. Can’t wait to see what else comes out of Ember!” — Eric, Carlsbad, Calif., on starbucks.com

PHASE CHANGE MATERIAL

What should a North American PCM manufacturers association focus on?

Leading U.S. makers of phase change material will meet Sunday in Clearwater Beach, Fla., to discuss the possible formation of a North American PCM manufacturers association.

The discussion, led by Dr. Jan Kosny of the Fraunhofer Center for Sustainable Energy Systems, will take place at the end of an all-day workshop on thermal mass. The workshop is part of the Buildings XIII Conference. Entropy Solutions, Phase Change Energy Solutions, Applied Innovation Group and Cool Composites are among the companies planning to attend.

Kosny has listed lack of material standards and performance criteria among the major challenges facing the PCM industry. A North American manufacturers association could be a driving force in developing such standards, promoting wider use of PCMs and influencing the political landscape in their favor, much as the RAL Quality Association PCM is doing in Europe.

If you’re planning to attend the meeting, I look forward to meeting you. If not, perhaps you would like to share your thoughts on this topic vie email or on LinkedIn: What areas do you think such an organization should focus on? PCM performance and standards? Government subsidies for HVAC and construction applications? LEED points eligibility? Industry support of academic research?

Maurizio Zaglio, business development manager at Sunamp Ltd., suggests a laser focus on establishing quality standards:

“A standard method for testing PCM should be developed. Too often data sheets with bold claims are published without a clear description of the method and testing procedures. I am not aware if such a standard already exists in Europe, but if so, it would probably be good to be as close as possible to that, as it is really annoying and expensive for companies in both markets to run multiple tests on all materials.

“A standard method for testing PCM should be developed. Too often data sheets with bold claims are published without a clear description of the method and testing procedures. I am not aware if such a standard already exists in Europe, but if so, it would probably be good to be as close as possible to that, as it is really annoying and expensive for companies in both markets to run multiple tests on all materials.

“If there are intentions to also consider PCM storage at system level, I again believe that a standard should be develop to certify their performances. Additionally, clarity would be needed about the legislation to follow to obtain the required certifications to sell these products (is it water tanks legislation? Maybe it cannot always be applied to PCM storage), and eventually lobbying to develop a tailored set of rules for them. “

AGRICULTURE

New wave of greenhouses use PCM to regulate temperature

Traditional greenhouses are not all that green. Poor insulation and inefficient heating and cooling systems boost energy consumption and operating costs.

Colorado-based Ceres Greenhouse Solutions is among the growing number of companies offering commercial growers and backyard gardeners a better way. Ceres has designed and built hundreds of energy-efficient, year-round greenhouses since 2011. Key features include the use of free solar energy for both heating and cooling, improved insulation and phase change materials.

“We specialize in passive solar design — maximizing the use of solar energy for year-round heating,” says Lindsey Schiller, director of marketing and business development. “These [greenhouses] use a combination of insulation and strategic placement of glazing (glass or plastics). The result is a more insulated and energy-efficient greenhouse capable of growing year-round in harsh climates with very little energy use. We also are well known for using a ground-to-air-heat exchanger we call the GAHT system, as well as integrating other sustainable / energy-efficient / renewable heating cooling systems.”

“We specialize in passive solar design — maximizing the use of solar energy for year-round heating,” says Lindsey Schiller, director of marketing and business development. “These [greenhouses] use a combination of insulation and strategic placement of glazing (glass or plastics). The result is a more insulated and energy-efficient greenhouse capable of growing year-round in harsh climates with very little energy use. We also are well known for using a ground-to-air-heat exchanger we call the GAHT system, as well as integrating other sustainable / energy-efficient / renewable heating cooling systems.”

Ceres uses film panels filled with phase change material to provide passive temperature control. The panels, sized to fit in a typical stud bay, help even out day-night temperature swings and reduce the need for active heating and cooling. They are typically installed in the north wall of a greenhouse.

Ceres originally used Phase Change Energy Solutions‘ BioPCM but recently switched to Insolcorp’s Infinite R, a salt hydrate. The company sells the PCM for $3.50 a square foot.

Another method for passive temperature regulation: fish tanks. Ceres recently announced a partnership with Colorado Aquaponics, a company that specializes in pre-fabricated aquaponics greenhouses. Ceres now offers kits that pair space-efficient aquaponic systems with highly efficient year-round greenhouses.

Can PCMs play a role in these hybrid greenhouses?

“Yes,” says Schiller, describing the technologies as complementary. “Greenhouses usually need several strategies to help control temperatures … not just one.”

PATENTS

Storage evaporator having PCM for use in vehicle air conditioning system

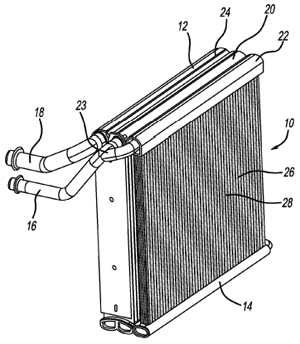

U.S. patent application 20160347146 (inventors Lim Wijaya and Nickolaos Economou, Auburn Hills, Mich.):

“A storage evaporator for an air conditioning system in a vehicle is provided that includes phase change material-containing tubes arranged side-by-side in contact with refrigerant-containing tubes. The storage evaporator includes an upper coolant tank, a lower coolant tank, refrigerant-containing tubes fluidly connecting said tanks; and phase change material-containing tubes provided in contact with said refrigerant tubes. The refrigerant tubes have flat sides and the phase change material-containing tubes have flat sides. The flat sides of the refrigerant tubes are attached to the flat sides of said phase change material-containing tubes. The phase change material may be any of several materials and may [be a] eutectic, a salt hydrate, and an organic material. In operation, cold energy is stored in the phase change material when the air conditioning compressor is in its “On” position. This cold energy is released from the phase change material when the compressor is in its “Off” position.”

“A storage evaporator for an air conditioning system in a vehicle is provided that includes phase change material-containing tubes arranged side-by-side in contact with refrigerant-containing tubes. The storage evaporator includes an upper coolant tank, a lower coolant tank, refrigerant-containing tubes fluidly connecting said tanks; and phase change material-containing tubes provided in contact with said refrigerant tubes. The refrigerant tubes have flat sides and the phase change material-containing tubes have flat sides. The flat sides of the refrigerant tubes are attached to the flat sides of said phase change material-containing tubes. The phase change material may be any of several materials and may [be a] eutectic, a salt hydrate, and an organic material. In operation, cold energy is stored in the phase change material when the air conditioning compressor is in its “On” position. This cold energy is released from the phase change material when the compressor is in its “Off” position.”

Insulated storage and transport system

U.S. patent application 20160347532 (applicant Savsu Technologies, Bethpage, N.Y., )

“A thermal storage system includes a thermally insulated storage container and a payload container adapted to retrievably house a temperature sensitive payload. The system includes layers of first and second phase change materials arranged in a stack with the payload container. The first phase change material has a phase change temperature within a target temperature range of the payload, and the second phase change material has a phase change temperature outside the target temperature range. The layers are arranged to isolate the payload from the second phase change material. In the case of biological materials that must not freeze while stored in the container, this arrangement enables a cold pack containing the layers of phase change materials to be placed in direct contact with the contents container even with a cold pack starting temperature well below the freezing point of the contents.”

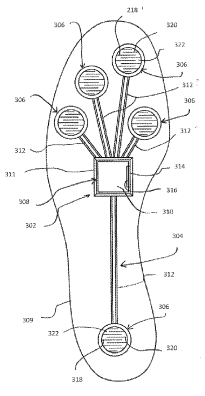

Athletic activity monitoring device with energy capture

U.S. patent application 20160351775 (applicant Nike Inc., Beaverton, Ore.):

“An energy harvesting device configured to be integrated into an item of clothing, comprising: an insulated container, comprising: an outer membrane having a first side in contact with an external environment and a second side that defines at least a portion of an internal cavity; an outer heat exchanger extending though the outer membrane, the outer heat exchanger comprising at least one surface in contact with the external environment; a thermoelectric generator module positioned within the internal cavity, the thermoelectric generator sandwiched between the outer heat exchanger and an inner heat exchanger; and an expandable membrane encapsulating a mass of phase-change material, at least a portion of the expandable membrane coupled to the inner heat exchanger, wherein the outer heat exchanger, the thermoelectric generator, and the inner heat exchanger are configured to allow bi-directional conduction of between the phase-change material and the external environment, and wherein the phase-change material is configured to store a portion of heat energy absorbed during a dryer cycle as the item of clothing is laundered.”

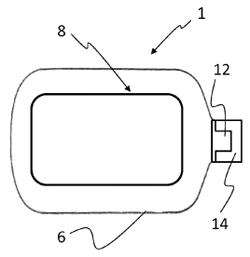

Heat device having latent heat storage means

U.S. patent application 20160346116 (applicant WFI Wärmflascheninnovation UG, Gröbenzell, Germany):

“Heating device (1) to be brought into at least indirect contact with a living being, at least comprising a receiving space (2) to hold a material that is able to flow (4), wherein the receiving space (2) is formed at least partially by a flexible wall (6), wherein the flexible wall (6) is able to have at least indirect contact with a living being, characterised in that it has a latent heat storage means (8), whereby the latent heat storage means is arranged in such a way, that at least temporarily, temperature control of the material that is able to flow may be brought about by the latent heat storage means (8), wherein the latent heat storage means (8) has a phase change material, wherein the phase change material absorbs energy during an endothermic change of state due to warming and releases energy in the form of heat during an exothermic change of state and the amount or mass of phase change material being such that with the receiving space filled to at least ⅔ with a material that is able to flow that is at a temperature above the melting point of the phase change material, the endothermic change of state of the phase change material at an ambient temperature of 20° C. may be brought about only partially.”

“Heating device (1) to be brought into at least indirect contact with a living being, at least comprising a receiving space (2) to hold a material that is able to flow (4), wherein the receiving space (2) is formed at least partially by a flexible wall (6), wherein the flexible wall (6) is able to have at least indirect contact with a living being, characterised in that it has a latent heat storage means (8), whereby the latent heat storage means is arranged in such a way, that at least temporarily, temperature control of the material that is able to flow may be brought about by the latent heat storage means (8), wherein the latent heat storage means (8) has a phase change material, wherein the phase change material absorbs energy during an endothermic change of state due to warming and releases energy in the form of heat during an exothermic change of state and the amount or mass of phase change material being such that with the receiving space filled to at least ⅔ with a material that is able to flow that is at a temperature above the melting point of the phase change material, the endothermic change of state of the phase change material at an ambient temperature of 20° C. may be brought about only partially.”

IN BRIEF

• A Lehigh University student has been honored for his research on the use of phase change materials to improve the efficiency of power plants and reduce the pollutants they emit. Joshua Charles, who is pursuing a doctorate in mechanical engineering, received a scholarship from the Air Pollution and Educational Research Grant program. He is experimenting with several variations of hydrated salt to improve the performance of the air-cooled condensers used in some power plants.

• The Storm Wave, the electric motorcycle developed by a team at Eindhoven University of Technology in the Netherlands, completed an around-the-world tour last month, covering 23,000 kilometers in 80 days. The Wave features swappable 28.5 kWh lithium-ion battery packs cooled by phase change material. Team members showed off the bike last week on “Zapplive,” a Dutch television show.

• The Storm Wave, the electric motorcycle developed by a team at Eindhoven University of Technology in the Netherlands, completed an around-the-world tour last month, covering 23,000 kilometers in 80 days. The Wave features swappable 28.5 kWh lithium-ion battery packs cooled by phase change material. Team members showed off the bike last week on “Zapplive,” a Dutch television show.

• Greentech Media‘s Jason Deign lists Eco-Tech Ceram of France as one of 12 European energy storage startups to watch. ETC says its ceramic thermal storage medium is 92 percent efficient. The technology could be used to capture some of the 3,500 terawatt-hours of heat lost from industrial processes every year.

• New from QYResearch: “United States Thermal Energy Storage (TES) Market Report 2016.”

• A team from the Universidad Politécnica de Madrid in Spain recently got a taste of zero gravity aboard an A310 Airbus as part of the European Space Agency‘s “Fly Your Thesis” program. The team developed an experiment to analyze the melting process of phase change materials in weightlessness conditions.

• C-Therm is promoting its TCi thermal conductivity analyzer as a tool to directly measure “thermal effusivity,” a material’s ability to exchange thermal energy with its surroundings. Sarah Ackermann, laboratory services manager at Thermal Analysis Labs, says direct measurement of a PCM’s thermal effusivity is not subject to “errors associated with the assumption of constant density and thermal conductivity the way most of the DSC calculations are.”

• Registration is open for “Cone Calorimeter: Quantifying Easily Flammability & Heat Release Rate,” an online course offered by SpecialChem.com. The instructor is Richard Hull, professor of chemistry and fire science at the University of Central Lancashire. The course will be held at 10 a.m. EST on Dec. 8. The cost is $309 for three participants on a single connection.

• Nominations are being accepted for the Thomas H. Smouse Memorial Fellowship, which is awarded to a graduate student doing research in areas of interest to the American Oil Chemists’ Society. The recipient will receive a $10,000 stipend and $5,000 in research and travel funds. Nominations are due by Jan. 15, 2017.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Applied Thermal Engineering:• Phase diagrams, eutectic mass ratios and thermal energy storage properties of multiple fatty acid eutectics as novel solid-liquid phase change materials for storage and retrieval of thermal energy

• A polyethylene glycol/hydroxyapatite composite phase change material for thermal energy storage

• Hygrothermal performance improvement of the Korean wood frame walls using macro-packed phase change materials

• Preparation and Characterization of Polyethylene Glycol (PEG) Hydrogel as Shape-stabilized Phase Change Material

From Carbon:

• Reinforcing and shape stabilizing of phase-change material via graphene oxide aerogel

From Energy Procedia:

• PCM-enhanced Lime Plasters for Vernacular and Contemporary Architecture

• Characterisation and Enhancement of Phase Change Slurries

• Packed-bed Thermal Energy Storage Analysis: Quartzite and Palm-Oil Performance

From Applied Energy:

• Application of material assessment methodology in latent heat thermal energy storage for waste heat recovery

• 1-octadecanol@hierarchical porous polymer composite as a novel shape-stability phase change material for latent heat thermal energy storage

From Journal of Chemical Thermodynamics:

• Thermal properties and reliability of eutectic mixture of stearic acid-acetamide as phase change material for latent heat storage

From Renewable Energy:

• Analysis of the technical, environmental and economic potential of phase change materials (PCM) for root zone heating in Mediterranean greenhouses

From Aalborg University, Denmark:

• Analysis of the technical, environmental and economic potential of phase change materials (PCM) for root zone heating in Mediterranean greenhouses [pdf]

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 950 of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this week include Grigoriy Barkhudaryan, general director of LLC Biotrans, Russia; Paula Timmermans, account manager at OptiVolt B.V., Netherlands; Loïc Picard, R&D project manager at Hutchinson, France; Gonçalo Pereira, postdoctoral associate at MIT, Massachusetts; and Augusto Vaime, business development director at Insulated Packaging Concepts, Spain.