The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

NEW PRODUCTS

ThermAvant’s new coffee mug is designed to get the ‘burn’ out faster

ThermAvant Technologies, which introduced the temperature-regulating Lexo travel tumbler in 2016, introduced a new mug this summer called Burnout. The new model is designed to cool hot beverages to a drinkable temperature of 140 degrees F within minutes and keep it there for hours.

ThermAvant founder Bill Ma, an engineering professor at the University of Missouri, says the new mug has faster cooling times, a new lid that limits residue buildup and a lifetime warranty. The Burnout comes in two sizes: 12 ounces ($79.99) and 16 ounces ($99).

The mugs are made in ThermAvant’s 4,000-square-foot manufacturing plant in Columbia, Mo. The company plans to move to a new facility with about 20,000 square feet of space later this year.

Ma answered questions about the new product via email:

Q: How is the Burnout mug different from your Lexo models? Both use biobased phase change material to regulate temperature.

Q: How is the Burnout mug different from your Lexo models? Both use biobased phase change material to regulate temperature.

A: “1. The cooling rate increases from 4-8 minutes to 2-6 minutes, depending on mug size and initial coffee temperature. The Burnout mug has an item inside to enhance heat transfer. 2. The drinking lid is updated. If you compare the Lexo lid with the Burnout lid, you can find the difference. 3. The Burnout mug has a red or black powder painting, which is unique. 4. The Burnout mug is made in USA. 5. Each mug has a unique number. When the customer purchases it, he or she can register online and get the lifetime warranty, which will provide the best service. 6. The luxury packaging box.”

Q: Why did you decide to use a new name and new website for this product?

A: “The Burnout name is for taking the ‘burn’ ‘out,’ which can directly tell the feature of our mugs.”

Q: Do you plan to continue to manufacture and sell the Lexo models?

A: “Not in USA.”

Q: In a news account, the PCM in the Burnout is said to be “charged” as part of the assembly process. Describe how the PCM is inserted into the walls of the product and then solidified.

A: “We spent almost two years to develop the confidential equipment to charge PCM, which is confidential.”

Q: Talk about your plans to produce “high-, standard- and low-temperature variants of Burnout.” What three temperatures are you focusing on?

A: “In the near future, we are going to have high-, standard- and low-temperature mugs.”

Q: Anything else you’d like to add?

A: “We are going to launch instant drinking mugs, and two-temperature mugs in 2019.”

PATENTS

Encapsulation

U.S. patent application 20180235893 (Procter & Gamble Co., Cincinnati, Ohio):

“An improved process of making a benefit agent delivery particle and consumer products incorporating such particles are disclosed. The process comprises the steps of providing a first composition of water phase 1, water phase 2 and water phase 3. Water phase 1 comprises water and an initiator; water phase 2 comprises water, a water-soluble or dispersible amine(meth)acrylate or hydroxyl(meth)acrylate and a multifunctional (meth)acrylate. Water phase 3 comprises water, and carboxyalkyl(meth)acrylate and a base or quarternary ammonium acrylate. The first two water phases are combined to prereact the hydroxy- or amine(meth)acrylate and the multifunctional (meth)acrylate to form a multifunctional hydroxyl-amine(meth)acrylate pre-polymer. The pre-polymer is combined with water phase 3; then an emulsion is formed by emulsifying under high shear agitation a second composition into said first composition; said second composition comprising an oil phase comprising an isocyanate and a benefit agent core material thereby forming a wall surrounding the benefit agent core material.”

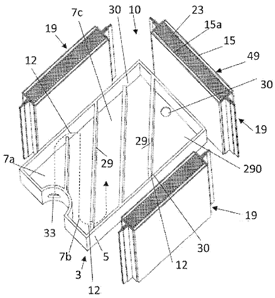

Thermal device for a fluid, with baffles, and associated circuits

U.S. patent application 20180238635 (applicant Hutchinson, Paris, France):

U.S. patent application 20180238635 (applicant Hutchinson, Paris, France):

“A thermal device comprising a fluid circulation circuit in which the fluid circulates over time at different temperatures, and a thermal store and heat exchanger arranged on said circuit and enclosing an interior volume in which the fluid circulates, and in which are arranged elements that store and release thermal energy, of PCM type, in contact with the fluid, for heat exchanges. The interior volume of the store and heat exchanger is provided with baffles.”

Related:

U.S. patent application 20180238636: Unit for storing thermal energy

Phase change compositions

U.S. patent application 20180237676 (applicant Sunamp Ltd., Edinburgh, Scotland):

“There are herein described phase change materials containing sodium acetate trihydrate having improved homogeneity, a process for the preparation of said materials, and their utility in phase change systems. More particularly, the present invention relates to the use of phase change compositions comprising sodium acetate trihydrate, at least one alkali soluble polymer for inhibition of sodium acetate anhydrous crystal formation in sodium acetatetrihydrate containing phase change materials, and at least one sodium acetate trihydrate nucleation promoter, and, if a lower phase change temperature is required, at least one melting point depressing agent.”

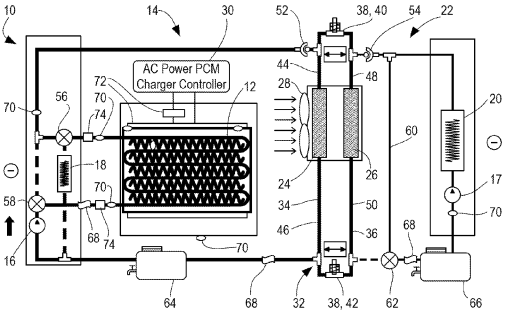

Multi-mode cabin heating system with dual heating source

U.S. patent application 20180236843 (applicant MAHLE International GmbH, Stuttgart, Germany):

“A heating system for an automotive passenger cabin includes a blower fan generating an air flow; a first heater core downstream of the blower fan; a second heater core downstream of the first heater core; a coolant loop with a first branch and a second branch, wherein the first heater core is disposed in the first branch and the second heater core is disposed in the second branch; a change-over valve arrangement having a first setting establishing fluid communication between the first and second heater cores by connecting the first and second branches in two locations on opposite sides of the first and second heater cores. The change-over valve arrangement has a second setting separating the fluid communication between the first and second heater cores by disconnecting the first and second branches. The second branch or both the first and the second branch are connectable to a PCM heater.”

Lithium-ion battery system having temperature control function

U.S. patent application 20180241028 (applicants Bordrin Motor Corp. Inc., Southfield, Mich.; Huai’an Junsheng New Energy Technology Co. Ltd., Huai’an City, China); and Nanjing Shenghe New Energy Technology Co. Ltd., Nanjing City, China):

“A lithium ion battery system having a temperature control function includes a shell, a battery core, and a phase change material. The battery core is packaged in the shell, the shell is filled with the phase change material which is in contact with a surface of the battery core, and the phase change material includes sodium nitrate with crystal water, paraffin wax, white carbon black, polyacrylamide gel, and trimethylolpropane.”

IN BRIEF

• The second round of U.S. and China tariffs took effect this week, covering about $4.2 billion in chemicals and plastics. Based on 2017 exports to China, ICIS News says the U.S. commodity chemical products most affected are monoethylene glycol, styrene, EVA copolymers, linear low-density polyethylene, high-density polyethylene (HDPE) and ethylene dichloride.

• Va-Q-tec AG‘s management board has extended the contract of CEO Dr. Joachim Kuhn, the company’s founder, through Dec. 31, 2023.

• Va-Q-tec AG‘s management board has extended the contract of CEO Dr. Joachim Kuhn, the company’s founder, through Dec. 31, 2023.

• The South African utility Eskom has decided to scrap development of the 100MW Kiwano concentrated solar power plant and instead invest the money in battery storage.

• Pelican BioThermal has an opening for director of sales – Americas in the company’s U.S. office in Plymouth, Minn. The director will “oversee all aspects of the growth and development of BioThermal market” in North and South America. Job candidates researching Peli may want to watch the company’s latest videos, which show how to assemble the new CoolPall Flex temperature-controlled shipper.

• NorthVolt has an opening for a thermal/mechanical design engineer for battery system development at the company’s office in Stockholm, Sweden. NorthVolt is building one of the first European large-scale lithium-ion battery factories.

• New from TMR Research: “Thermal Energy Storage Market – Global Industry Analysis, Size, Share, Trends, Analysis, Growth, and Forecast 2017 – 2025“

• New from QY Research: “Global Phase Change Materials (PCM) Market Professional Survey Report 2018“

• New from Reports and Markets: “Global Cold Chain Equipments Market Insights, Forecast to 2025“

• In an Imaginasium interview, Encapsys President Mary Goggans talks about the Appleton, Wis., microencapsulator’s transition to a standalone company over the past two years.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Experimental Thermal and Fluid Science:• Thermal–hydraulic characteristics of ethylene glycol aqueous solutions containing microencapsulated paraffin

From Applied Thermal Engineering:

• Three-dimensional numerical and experimental investigation of the behavior of solar salts within thermal storage devices during phase change

From Renewable Energy:

• Numerical investigation on the effect of different parameters in enhancing heat transfer performance of photovoltaic thermal systems

From Energy Conversion and Management:

• Development of a calorific value controller using bimetal fin channel for PCM heat storage

• Experimental and numerical investigation for improving the thermal performance of a microencapsulated phase change material plasterboard

From Polymers:

• Fabrication and Performance of Composite Microencapsulated Phase Change Materials with Palmitic Acid Ethyl Ester as Core

From Cement and Concrete Composites:

• Elucidating the influences of compliant microscale inclusions on the fracture behavior of cementitious composites

From AIP Conference Proceedings:

• Simulation and validation of PCM melting in concentric double pipe heat exchanger

• Modeling and experimental validation of the thermal behavior of PCM using DSC input data

• Thermal behavior of melting paraffin wax process in cylindrical capsule by experimental study

From Energy and Buildings:

• A novel building material with low thermal conductivity: Rapid synthesis of foam concrete reinforced silica aerogel and energy performance simulation

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,300 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,300 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Michel Bosman of Tizzin B.V., Maasdijk, Netherlands; Nicola Difonzo, isothermal solutions consultant, Bari, Italy; Bengt-Simon Feth, general manager, Germany, at Marken, Frankfurt Am Main, Germany; and Ludvig Bellehumeur, director of project development at EnergyNest, Billingstad, Norway.