The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

BUILDING | CONSTRUCTION

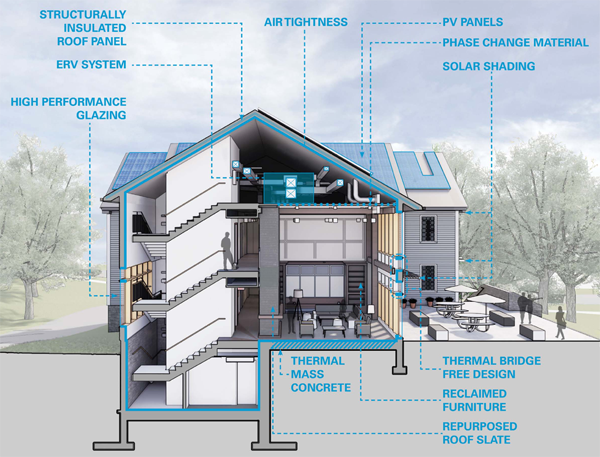

New dormitory features 1,800-plus square feet of PCM mats

A new dormitory at Williams College in Massachusetts is equipped with 18,200 square feet of mats filled with phase change material.

Garfield House, completed in time for the first students to move in this month, is designed to achieve Passive House PHIUS+ certification and LEED Gold certification. It features R-38 walls, R-60 roofs, triple-pane windows, high-efficiency energy recovery ventilation units, drainwater heat recovery and a 50 kw photovoltaic array.

The Infinite R PCM mats, made by Insolcorp LLC of New London, N.C., will help keep the passively cooled building comfortable when the weather is warm. The PCM is a salt hydrate with a peak melting point of 73 degrees F and a thermal storage capacity of about 170 joules per gram. The mats are deployed within Garfield’s interior walls and above ceilings.

Jacob Higginbottom, director of higher education design at SGA in Boston, was project manager. He first learned about the potential use of phase change material in building envelopes and interiors in March 2018.

Jacob Higginbottom, director of higher education design at SGA in Boston, was project manager. He first learned about the potential use of phase change material in building envelopes and interiors in March 2018.

“A member of our team had run across the Infinite R product at a trade show and our client was looking for ways to introduce passive cooling techniques since it’s their campus standard to build residence halls without active cooling,” said Higginbottom, right. “Upon research we convinced the client that this could help and they decided to give it a try.”

Garfield House has no active cooling system. Did that present any special challenges?

“The fact that Garfield did not have cooling wasn’t necessarily a challenge for the PCM, but perhaps was more of an opportunity for the project itself,” said Mick Dunn, Insolcorp president. “The project wasn’t without a cooling source altogether. The design team implemented well-designed ERV/ventilation to leverage cool overnight temperatures. As part of the Passive House design process, some issues were identified with cooling and being able to maintain comfort without the introduction of A/C. So we worked with them to analyze a suitable amount of PCM to help address that cooling issue and help negate the need for investment in mechanical cooling other than ventilation.

“We’ve had numerous applications where the PCM has been used with no active cooling. Most of these have been very large industrial applications where the PCM has been used to control peak plant temperatures in buildings with very high internal heat loads. The results have been very good, and we’ve seen reductions as much as 10 to 15F compared with baseline temps. Sometimes we’ll be using a higher temp PCM to promote natural re-freezing. In more conventional occupied office/housing applications we’d typically still be looking for some kind of mechanical cooling mechanism such as ventilation if air conditioning is not present. And we’d probably be more likely to consider this as a viable strategy in climates such as California or New England than say Florida where humidity and overnight temperatures are very high.”

The engineering firm Thornton Tomasetti of New York conducted whole building energy modeling in WUFI Passive, the program required by the Passive House Institute US (PHIUS). The models project cooling demand of 0.74 kBtu per square foot per year and a cooling load of 1.64 Btu per hour per square foot. A PCM thermal simulation model projects a peak cooling reduction of 10 degrees F.

Will the building’s actual performance be measured against these metrics in the first year of occupancy?

Elsa Mullin, senior sustainability consultant at Thornton Tomasetti, says PHIUS “does not require post-occupancy measurement and verification after initial occupancy.”

Higginbottom said LEED certification for the design portion is completed. All construction requirements have been submitted and he expects a LEED Gold certificate from the U.S. Green Building Council by the end of the month.

He said the use of PCM won’t be a factor in the certification process.

“A building like this can easily achieve LEED Gold without the use of this material,” he said. “PCM was introduced to address thermal comfort. Active cooling does not dramatically affect the building energy consumption in a use type like this (most loads come from domestic HW and plug loads and ventilation fans which are still required irrespective of cooling design).”

It’s the first time Higginbottom has used PCM in a project. He hopes to use it in future projects.

“The interesting part about this product is the ability to fine-tune a building towards net zero or net positive and also to flatten out the demand for cooling and possibly downsize equipment in the future and save money on operating and up-front costs,” he said. “We would like to have more research to back that up, but it’s a speculation on our part that this would be a benefit to building owners’ first costs and life-cycle costs.”

PATENTS

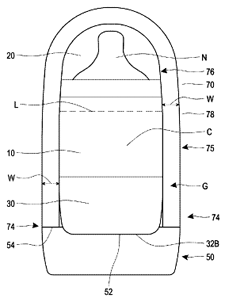

Actively heated or cooled infant bottle system

U.S. patent application 20190231121 (applicant Ember Technologies Inc., Westlake Village, Calif.):

“An infant bottle feeding system includes an infant bottle with a chamber that receives a liquid, heating or cooling elements operable to heat or cool liquid in the chamber and sensors operable to sense parameters of the liquid in the chamber. The system optionally includes an electronic base removably attached to a bottom surface of the infant bottle and operable to deliver power to electronics in the infant bottle. The system optionally includes a thermal cover that fits over the infant bottle and releasably couples to the electronic base to enclose the infant bottle, the thermal cover insulating the infant bottle and inhibiting heat loss of the liquid in the chamber. The electronic base delivers power to the heating elements and sensors in the infant bottle only when the infant bottle is on the electronic base. The infant bottle, thermal cover and electronic base define a single travel pack unit when coupled together.”

“An infant bottle feeding system includes an infant bottle with a chamber that receives a liquid, heating or cooling elements operable to heat or cool liquid in the chamber and sensors operable to sense parameters of the liquid in the chamber. The system optionally includes an electronic base removably attached to a bottom surface of the infant bottle and operable to deliver power to electronics in the infant bottle. The system optionally includes a thermal cover that fits over the infant bottle and releasably couples to the electronic base to enclose the infant bottle, the thermal cover insulating the infant bottle and inhibiting heat loss of the liquid in the chamber. The electronic base delivers power to the heating elements and sensors in the infant bottle only when the infant bottle is on the electronic base. The infant bottle, thermal cover and electronic base define a single travel pack unit when coupled together.”

Eco smart panels for energy savings

U.S. patent application 20190249904 (applicant SIDCO Homes Inc., San Jose, Calif.):

“An eco-smart panel is described comprising a solar thermal panel, a phase change material, a metal foil layer, and a structural frame constructed of materials including wood studs, gypsum, or fiberglass-reinforced concrete. The materials may be variously configured to create modular systems for fabricating buildings or structures. Eco-smart panels may be utilized to create buildings or structure with enhanced energy efficiency, increased fire resistance, increased flood resistance, and decreased construction cost and time.”

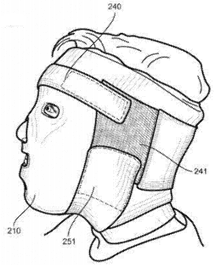

PCM for medical and cosmetic applications

U.S. patent application 20190231598 (applicant Alps South LLC, St. Petersburg, Fla.):

“A garment using a phase change material that change phase from solid to liquid at a low or high temperatures situated within a gel matrix. The phase change material may be used after surgical procedures to reduce swelling, edema and bruising. The gel matrix allows the material of the present invention to maintain a conformable and elastic form at room temperature. This invention provides the novelty of a low or high temperature phase change material that is conformable to surfaces or volumes of varying geometry.”

Temperature regulating polyurethane gel

U.S. patent application 20190249058 (applicant Technogel Italia S.r.L., Pozzoleone, Italy):

“A method for the production of a temperature regulating polyurethane gel composition and corresponding articles includes fatty acid esters as a phase change material (PCM) directly incorporated in the fluid phase of a polyurethane gel without encapsulation. The liquid or melted PCM is solved in the polyol component of the gel and is able to crystallize and melt within the gel structure reversibly. The polyurethane gels are under-crosslinked and include an at least nominal three functional ethylene oxide-comprising alkylene oxide polyether polyol with 0 to 40% EO and an isocyanate with an effective functionality of from 1.5 to 3.5. The gels are useful in articles where the gel can be positioned close to the human body for temperature regulating purposes, and especially to improve the sleeping comfort of a resting person.”

IN BRIEF

• Innovate UK’s Knowledge Transfer Partnership has awarded funding to a joint effort by AMP Clean Energy and the University of Birmingham to develop a thermal energy storage system. The system will incorporate phase change material developed by the university for use in AMP’s Urban Reserve flexible electricity generation plants, which will turn waste heat into electricity. The amount of funding was not disclosed.

• Geocryologist Christopher Stevens of SRK North America will give a PCM-related presentation at next week’s International Conference on Cold Regions Engineering in Quebec City: “Phase Change Materials – Innovation in Adaptation Technology to Address Permafrost Thaw” (Aug. 21).

• Australian start-up 1414 Degrees has announced a joint project with Nectar Farms to test “SmartFarm” applications of 1414’s technology, which stores electricity as thermal energy by heating and melting containers full of silicon.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Applied Thermal Engineering:• Application and sensitivity analysis of the phase change material hysteresis method in EnergyPlus: A case study

From Scientific Reports:

• A promising form-stable phase change material prepared using cost effective pinecone biochar as the matrix of palmitic acid for thermal energy storage

From Applied Energy:

• Geometry-induced thermal storage enhancement of shape-stabilized phase change materials based on oriented carbon nanotubes

• Passive cooling through phase change materials in buildings. A critical study of implementation alternatives

From Cement and Concrete Composites:

• Thermal responses of concrete slabs containing microencapsulated low-transition temperature phase change materials exposed to realistic climate conditions

From Solar Energy Materials and Solar Cells:

• Preparation and thermal properties of low melting point alloy/expanded graphite composite phase change materials used in solar water storage system

• Frost and high-temperature resistance performance of a novel dual-phase change material flat plate solar collector

From Energy:

• Novel micro-encapsulated phase change materials with low melting point slurry: Characterization and cementing application

From IOP Conference Series: Materials Science and Engineering:

• Thermal performances and characterization of microencapsulated phase change materials for thermal energy storage

From Journal of Physics: Conference Series:

• Effect of thermal performance on melting and solidification of lauric acid PCM in cylindrical thermal energy storage

From Construction and Building Materials: • A sodium acetate trihydrate-formamide/expanded perlite composite with high latent heat and suitable phase change temperatures for use in building roof

From Materials Research Express:

• Investigation of magnesium nitrate hexahydrate based phase change materials containing nanoparticles for thermal energy storage

From Journal of the Brazilian Society of Mechanical Sciences and Engineering:

• Selection of phase change material for solar thermal storage application: a comparative study

From Renewable Energy:

• Experimental study on the thermal performance of a grey water heat harnessing exchanger using phase change materials

From International Journal of Energy Research:

• Climate applicability study of building envelopes containing phase change materials

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,490 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,490 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcome Kai Schwarz, lead engineer, automotive structures electrical vehicles, Constellium Singen GmbH, Gottmadingen, Germany; Anuksha Kondulkar, specialty chemicals industry analysis and research at MarketsandMarkets, Northbrook, Illinois; Amin Zayani, CEO at MedAngel, Berlin, Germany; Mark Gibbons, senior regional energy projects officer at Midlands Energy Hub, Nottingham City Council, England; Michael Ulmer, head of product management, Textilcolor AG, Sevelin, Switzerland; Varun Gupta, Ph.D. scholar at National Institute of Technology, Jalandhar, India; and Nima Farzadnia, researcher at Missouri University of Science and Technology, Rolla, Missouri.