The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

THERMAL ENERGY STORAGE

Extremely high-temperature TES prototype under development in Europe

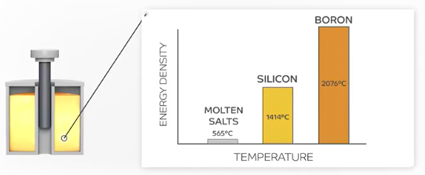

At seven locations around Europe, a consortium of universities, R&D centers and an Italian company is investigating materials and devices for thermal energy storage at temperatures of up to 2000º C, well beyond the maximum operating temperatures of systems in use today.

The AMADEUS project, funded by the European Union’s Horizon 2020 program, aims to build a prototype of a system that stores electricity in the form of extremely dense heat, using a solid state device known as a hybrid thermionic-photovoltaic converter. The project’s success hinges on the development of novel silicon and boron alloys with melting temperatures well above 1000º C and energy densities of more than 1 kilowatt hour per liter.

Alejandro Datas, a research scientist at the Technical University of Madrid’s Institute of Solar Energy, is the project’s scientific coordinator. He responded to questions about the project by email.

Alejandro Datas, a research scientist at the Technical University of Madrid’s Institute of Solar Energy, is the project’s scientific coordinator. He responded to questions about the project by email.

Q: What is your role as scientific coordinator?

A: My role is to coordinate the project activities and make them converge at the end in a single prototype, which will demonstrate the feasibility of this new concept. I’m also involved in the development of the infrared-sensitive PV cell (or thermophotovoltaic cell) that will be used to convert radiant heat into electricity in these systems.

Q: Work on the project began about seven months ago and is scheduled to continue through 2019. What important milestones have you reached so far, and what are the next important milestones?

A: During the first six months of the project, we have characterized some Si-B alloys with different compositions to determine their most important thermophysical parameters, such as latent heat and thermal conductivity. By means of solubility and wettability experiments, we have also studied the interaction of these alloys with some nitride- and carbide- refractories that are intended to be used for the container walls. Also, we have fabricated an experimental setup that will enable the characterization of the energy converters at very high temperatures. The next expected milestones will be the fabrication of the first generation of hybrid thermionic-photovoltaic converters, as well as the determination of the optimal Si-B alloy composition based on an exhaustive analysis of their thermophysical properties and their reactivity with the container walls.

Q: Can you describe, briefly, the PCM you are developing, and what is meant by “the silicon-boron system”?

A: The Si-B system refers to an alloy containing silicon and boron elements in some specific proportions. Silicon and boron have two of the highest latent heats among all the elements in the periodic table. But they show some important drawbacks: in the case of silicon, it expands upon solidification (like water) which leads to very severe constraints for the vessel design; in the case of boron, it has a high cost. The Si-B system is expected to exploit the best of both elements. For instance, the eutectic composition of this alloy (having only 5% of boron) is expected to notably improve the properties of pure silicon PCM at a reasonable cost increment. In brief, Si-B alloys have potential to meet the main requirements for being considered an ideal PCM: low cost, high latent heat and high thermal conductivity. Surprisingly, very little attention has been paid to this system so far, and to our knowledge, AMADEUS is the very first project to investigate these materials in detail for energy storage applications.

Q: What are some of the PCM containment materials and structures under consideration?

A: One advantage of Si-B PCMs is their high thermal conductivity. Thus, they could be stored in relatively large containers without needing very advanced encapsulation arrangements. This minimizes the impact of the container in the final cost of the system. In order to achieve the minimum interaction between the container and the Si-B PCM, we are investigating several kinds of vessel liners based on nitrides (e.g. BN or Si3N4), carbides (e.g. SiC) and oxides (e.g. SiO2).

Q: How does AMADEUS differ from the molten silicon storage technology under development by 1414 Degrees in Australia?

A: Apparently, 1414 Degrees uses pure silicon PCM and “conventional” dynamic engines to transform latent heat into electricity. 1414 Degrees probably needs to reach the market soon, so that they must use reliable and mature technologies. In AMADEUS we are exploring new technologies with greater potential that still require further development. This is the case of Si-B alloys, which may enable higher energy densities and more efficient vessel designs. This is also the case of the thermionic and thermophotovoltaic converters, which will eventually enable more efficient, compact and simpler systems, not requiring working fluids or moving parts. We certainly hope that companies such as 1414 Degrees, and others that could start activities in the near future, could benefit from the results of AMADEUS project.

AUTOMOTIVE

Dutch company is filling aluminum auto body structures with PCM

Dutch aluminum producer Constellium NV has expanded its Michigan plant to supply PCM-filled aluminum body structures for use in electric vehicles. The body structures work like this, reports Automotive News:

“The structure consists of extruded aluminum members that have a hollow cavity. Constellium fills the cavity with a phase change material, a substance that will absorb and release thermal energy in the course of freezing or melting. It is a waxlike material that acts as a passive cooling system for a battery.

“The properties of the phase change material — which can be engineered to the customer’s vehicle specs — enable the material to hold heat or to “melt” like a wax to carry heat away from the battery. By shielding the battery from temperature extremes, the body structure helps extend the battery’s life.”

Constellium CEO Jean-Mark Germain is bullish on the prospects for aluminum in the EV market.

“For vehicles to carry electric batteries,” he said, “they will be designed with aluminum structures to hold them. And those structures must do more than traditional metal body structures. They must provide thermal transfer capabilities to keep the battery cool or keep it warm in cold weather. So the structure actually becomes part of the power source.”

Constellium says its EV body structures will be in use in Europe within 16 months, and in the United States in 2019. The company declined to reveal the customer.

PATENTS

Temperature regulating polyurethane gels

U.S. patent application 20170210961 (applicant Technogel Italia, Vicenza, Italy):

“A method for the production of a temperature regulating polyurethane gel composition and corresponding articles includes fatty acid esters as a phase change material (PCM) directly incorporated in the fluid phase of a polyurethane gel without encapsulation. The liquid or melted PCM is solved in the polyol component of the gel and is able to crystallize and melt within the gel structure reversibly. The polyurethane gels are under-crosslinked and include at least nominal three functional ethylene oxide-comprising alkylene oxide polyether polyol with 0 to 40% EO and an isocyanate with an effective functionality of from 1.5 to 3.5. The gels are useful in articles where the gel can be positioned close to the human body for temperature regulating purposes, and especially to improve the sleeping comfort of a resting person.”

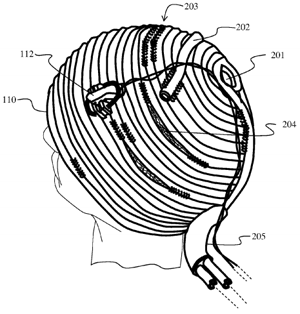

Self-managed portable hypothermia system

U.S. patent application 20170209304 (inventors Michael and Laura Zumbrunnen, Rochester, Minn.):

U.S. patent application 20170209304 (inventors Michael and Laura Zumbrunnen, Rochester, Minn.):

“A non-user assisted, portable, entirely self-managed capable hypothermia device to eliminate hair loss caused by the side effects of certain chemotherapy treatments or to reduce the metabolic rate of ischemic tissue along with the severity of swelling is disclosed. The device consists of a conformal cap system, a thermally conductive liquid located between the body part to be cooled and the cap system, thermal transfer fluids, phase change materials, thermally insulated cooler, physical measuring devices, mechanical and electrical components, a ‘smart’ user interface device, a battery, and an uninterruptible power controller.”

Systems and methods for thermal battery control

U.S. patent application 20170210196 (applicant Ford Global Technologies, Dearborn, Mich.):

“Methods and system for operating a thermal storage device of a vehicle system are provided. In one example, a method comprises estimating a temperature of a thermal battery after the battery and coolant included therein have reached thermal equilibrium, and determining a state of charge of the battery based on the estimated temperature and one or more chemical properties of two phase change materials included within the battery. Specifically, the thermal battery may include two phase change materials with different melting points for providing thermal energy to warm coolant in a vehicle coolant system.”

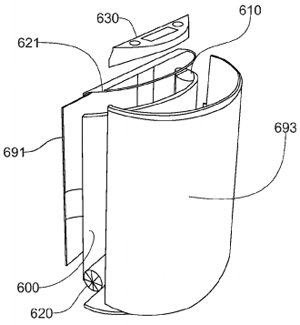

Device and method for storing thermal energy

U.S. patent application 20170219294 (applicant Muller & Cie, Paris, France):

U.S. patent application 20170219294 (applicant Muller & Cie, Paris, France):

“A device to store energy includes a phase change material (PCM), with a phase change temperature Tc, contained in a sealed container and constituting a storage core. A source to exchange heat with the PCM, at a temperature TA, to cause a phase change of the PCM. A recuperator to exchange heat with the PCM, at a temperature TB, to cause a phase change of the PCM in the opposite direction to the phase change produced by the source. A controller to control the heat flows between the PCM, the source and the recuperator. An apertured support in contact with the PCM in the sealed container and in thermal contact with the source and the recuperator.”

High strength microcapsules

U.S. patent application 20170216161 (applicant Procter & Gamble Co., Cincinnati, Ohio):

“According to the present disclosure, high strength microcapsules suitable for the encapsulation of hydrophobic core materials, especially phase change materials, are formed through an oil-in-water microencapsulation process in which the hydrophobic material is encapsulated in a polymer shell comprising the reaction product of one or more ethylenically unsaturated monomers which is wholly or partially soluble in the core material (the “core monomers”).”

Meat tenderizing using substrate with phase change materials

U.S. patent application 20170215439 (applicant Empire Technology Development, Wilmington, Del.):

“A meat tenderizing device is provided for meat tenderizing. The device can include a substrate having at least one structural reinforcing member. The substrate may be elastomeric, and may have a body of a material that is non-conductive. The structural reinforcing member can be longitudinally aligned to inhibit longitudinal shortening or longitudinal contraction of the device. The device can provide radial or lateral compression to maintain a longitudinal length or longitudinal stretching of meat contained therein. The substrate can include a conductive material distributed therein that is thermally or electrically conductive. The structural reinforcing member can be positioned so as to control stretching of the substrate. The device can also include a phase change member on a surface of at least a portion of the substrate. The phase change member can include a phase change hydrogel that is liquid at lower temperatures and a gel at higher temperatures.”

IN BRIEF

• Alphabet Inc.‘s secretive development lab is developing a system for storing renewable energy in tanks filled with salt and antifreeze. “The system takes in energy in the form of electricity and turns it into separate streams of hot and cold air,” Bloomberg reports. “The hot air heats up the salt, while the cold air cools the antifreeze, a bit like a refrigerator. … Flip a switch and the process reverses. Hot and cold air rush toward each other, creating powerful gusts that spin a turbine and spit out electricity when the grid needs it. Salt maintains its temperature well, so the system can store energy for many hours, and even days, depending on how much you insulate the tanks.”

• Pluss Advanced Technologies has received a 50 lakh grant (about $78,000 USD) under India’s Millennium Alliance Program to promote the use of the company’s MiraCradle cooling device in hospitals and neonatal care units across India. The device uses phase change material to treat birth asphyxia in newborns.

• Thermetrics LLC has introduced an 11-zone thermal baby manikin that features a thermally conductive carbon-epoxy shell, a “sweating skin system” and internal heater elements and temperature sensors. Nicknamed “Ruth,” the manikin can be used to evaluate the thermal properties of clothing, diapers, bedding, car seats and strollers.

• Thermetrics LLC has introduced an 11-zone thermal baby manikin that features a thermally conductive carbon-epoxy shell, a “sweating skin system” and internal heater elements and temperature sensors. Nicknamed “Ruth,” the manikin can be used to evaluate the thermal properties of clothing, diapers, bedding, car seats and strollers.

• Axiom Exergy and Ice Energy are on a list of 25 companies notable for developing innovative technologies to reduce energy consumption in commercial and industrial buildings.

• Croda International has announced the acquisition of Enza Biotech AB, a research enterprise established as a spin-out company from Lund University in Sweden.

• AkzoNobel has announced the winners of its 2017 Imagine Chemistry initiative, recognizing and supporting efforts to help solve real-life chemistry-related challenges and to uncover sustainable opportunities for the company’s specialty chemicals business. Among the winners is Industrial Microbes of Emeryville, Calif., for its work on the biocatalysis of ethylene to ethylene oxide.

• Ice Energy CEO Mike Hopkins and Magnum CAES CEO Richard Walje will be among the speakers at the Energy Storage North America conference in San Diego next week.

• ONE Aviation of Albuquerque, N.M., has selected Acme Aerospace to provide lithium ion battery systems to be used in ONE’s “Project Canada” aircraft. The Acme system features a proprietary phase change material to improve battery performance.

• Reuters reports that Dow Chemical and DuPont are seeing increased benefits in developing sustainable “green” products, as the chemical giants seek new areas of growth and build a stronger connection with millennials.

• TemperPack, a Virginia-based manufacturer of sustainable packaging for perishable goods, has raised $10 million in an investment round that will help it further expand operations and add jobs.

• Digital strategies “will have a significant impact on many areas of the chemical industry, with the potential to change value chains, lead to higher productivity and more innovation, and create new channels to market,” according to a McKinsey & Co. analysis.

• The Bioencapsulation Research Group has posted the program for the 3rd Latin-America Symposium on Microencapsulation, to be held in Chile Nov. 27-29.

• 1414 Degrees, the Australian startup that has developed a way to store electricity as thermal energy by heating and melting containers full of silicon, has posted openings for a chief financial officer and an energy storage and power network system analyst.

• New from QY Research: “Global Inorganic Advanced Phase Change Materials (PCM) Market Research Report 2017”

• New from Future Market Insights: “Energy Harvesting Market: Global Industry Analysis and Opportunity Assessment 2014 – 2020” and “Chilled Water Storage System Market: Global Industry Analysis 2012 – 2016 and Opportunity Assessment; 2017 – 2027“

• Sonoco ThermoSafe has launched a new range of reusable, universal solutions for the pharmaceutical and biologics markets. ChillTech is a pre-qualified range of 2°C to 8°C PCM systems providing temperature control from two days up to six days for payloads from 4L to 40L. The range uses Laminar Medica’s ChillPhase paraffin phase change material.

• Sonoco ThermoSafe has launched a new range of reusable, universal solutions for the pharmaceutical and biologics markets. ChillTech is a pre-qualified range of 2°C to 8°C PCM systems providing temperature control from two days up to six days for payloads from 4L to 40L. The range uses Laminar Medica’s ChillPhase paraffin phase change material.

• A new reference manual for the oleochemical industry is now available. “Fatty Acids: Chemistry, Synthesis, and Applications” presents new information on industrially important fatty acids including detailed descriptions of fatty acid crystallization, enzymatic synthesis and microbial production.

• Why haven’t phase change materials taken off in the UK construction industry? Ian Biggin of Phase Energy Ltd., which is developing novel shape-stabilized technologies, says the industry needs to address what he calls the “4Ps”: price, performance, proof and promotion.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Cement and Concrete Research:• Mechanical properties and microscale changes of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials

From Applied Energy:

• Impact of pressure on the dynamic behavior of CO2 hydrate slurry in a stirred tank reactor applied to cold thermal energy storage

From International Journal of Refrigeration:

• Parametric analysis of domestic refrigerators using PCM heat exchanger

From American Institute of Physics:

• Utilization of the PCM Latent Heat for Energy Savings in Buildings [pdf]

From Journal of Cleaner Production:

• LCA perspective to assess the environmental impact of a novel PCM-based cold storage unit for the civil air conditioning

From Renewable Energy:

• A calcium chloride hexahydrate/expanded perlite composite with good heat storage and insulation properties for building energy conservation

• Ionic compounds derived from crude glycerol: Thermal energy storage capability evaluation

• Comparative study of the thermal performance of four different shell-and-tube heat exchangers used as latent heat thermal energy storage systems

From Materials Today: Proceedings:

• Viscoelastic characterization of multifunctional composites incorporated with microencapsulated phase change materials

From Applied Thermal Engineering:

• Effect of phase change material wall on natural convection heat transfer inside an air filled enclosure

• A numerical study of building integrated with CaCl2·6H2O/expanded graphite composite phase change material

• Study of the thermal behavior of the composite phase change material (PCM) room in summer and winter

From Applied Polymer Science:

• Emulsion-electrospinning n-octadecane/silk composite fiber as environmental-friendly form-stable phase change materials

From Journal of Materials Chemistry A:

• Versatility of polyethylene glycol (PEG) in designing solid-solid phase change materials (PCMs) for thermal management and their application to innovative technologies

From Materials:

• Influence of Microencapsulated Phase Change Material (PCM) Addition on (Micro) Mechanical Properties of Cement Paste

• Investigation of the Dynamic Melting Process in a Thermal Energy Storage Unit Using a Helical Coil Heat Exchanger

From Energy and Buildings:

• Experimental analysis of thermal performance in buildings with shape-stabilized phase change materials

• Preparation and thermal properties of octyl, decyl, dodecyl and tetradecyl stearates as phase change materials for thermal energy storage

• Effect of PCM application inside an evacuated tube collector on the thermal performance of a domestic hot water system

From Solar Energy:

• Experimental investigation of water based photovoltaic/thermal (PV/T) system with and without phase change material (PCM)

• Heat transfer studies of building brick containing phase change materials

• Experimental investigations on stable supercooling performance of sodium acetate trihydrate PCM for thermal storage

From Solar Energy Materials and Solar Cells:

• Supercooling suppression and thermal behavior improvement of erythritol as phase change material for thermal energy storage

• MgCl2·6H2O-Mg(NO3)2·6H2O eutectic/SiO2 composite phase change material with improved thermal reliability and enhanced thermal conductivity