The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

AUTOMOTIVE

PCM keeps Embry-Riddle’s EcoCAR entry running cool

Batteries used in hybrid and electric cars work hard and run hot. Traditional cooling systems use an array of pumps, heat exchangers, cooling fans and hoses to manage that heat. Florida’s Embry-Riddle Aeronautical University needed something lighter and simpler for its entry in the Department of Energy’s EcoCAR 3 competition.

The solution: an aluminum cooling plate filled with biobased phase change material.

A team of mechanical engineering students at the school designed and built the plate under the direction of Sandra Boetcher, associate professor of mechanical engineering.

The school’s EcoCAR entry required that the plate use a PCM with a peak melting point of 45 degrees Celsius (113 degrees F). To achieve that temperature, the team selected two commercially available PCMs – PureTemp 37 and PureTemp 48 – and mixed them together.

Boetcher explains the photo at right:

Boetcher explains the photo at right:

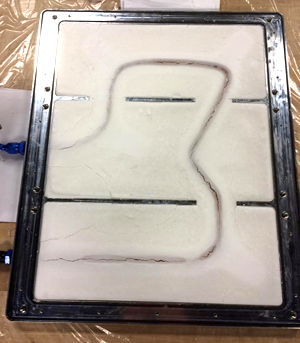

“That’s the inside of the plate before we sealed the aluminum lid on it. On the inside is a copper tube. At the time we put this in the car, we were under a strict deadline and did not have time to redo the bending of the copper tube. The copper tube feeds a cold ethylene-glycol/water mixture as backup for when the PCM has completely melted and needs to resolidify while the car is driving.

“I was concerned that the copper tube didn’t provide enough coverage of the area, but that cold plate has been in the car for the past 2.5 years and it works great. Actually, the back-up pump that runs the ethylene-glycol/water through the copper tube rarely even turns on which means that under our test-driving conditions, the cold plate is acting 100 percent passive. The terrible part of the PCM is that it loves to leak. We feel that there has been some leaking.”

The plate is lighter and simpler than a water-cooled system. “It doesn’t take any energy to run,” said Patrick Currier, an associate professor who advises the EcoCAR team. “We’re not wasting power cooling things. This is a totally passive system, so unless it leaks, it can’t fail.”

Embry-Riddle filed for a U.S. patent on the device in 2015.

“The diagrams in the patent are similar to what we have in the EcoCAR right now, although the geometry is a little different,” Boetcher said. “The research we are conducting is still on-going. The applications we envision could be anything that requires PCM – battery cooling, building technologies, etc.”

Embry-Riddle is one of 16 North American universities challenged to redesign a 2016 Chevrolet Camaro into a hybrid-electric car to reduce environmental impact, while maintaining the “muscle and performance” the car is known for.

The teams have had four years to develop their entries. The cars will be put to the test in a variety of events in Arizona and California in May. Winners will be chosen in 40-plus categories at an awards ceremony in Hollywood on May 22, with more than $100,000 in prize money at stake.

PATENTS

Compositions comprising latent heat storage materials

U.S. patent application 20180112114 (applicant Phase Change Energy Solutions, Asheboro, N.C.):

“In one aspect, compositions are described herein. In some embodiments, a composition comprises a latent heat storage material having a solid-to-gel transition between about 50° C. and about 100° C. at 1 atm. In some embodiments, a composition comprises a foam and a latent heat storage material dispersed in the foam, the latent heat storage material having a solid-to-gel transition between about −50° C. and about 100° C. at 1 atm.”

Thermal management system for fuel cell vehicle

U.S. patent application 20180114998 (applicant Hyundai Motor Co., Seoul, South Korea):

“A thermal management system for a fuel cell vehicle includes a first line including a coolant pump and a fuel cell stack, a second line including a coolant heater and a phase change material (PCM) and connected to the first line to form a first loop in which the coolant pump, the stack, the coolant heater, and the PCM are arranged, a third line including a radiator and connected to the first line to form a second loop in which the coolant pump, the stack, and the radiator are arranged, and an opening and closing valve opening and closing each of the first line, the second line, and the third line to allow the coolant to circulate in at least one of the first loop and the second loop, wherein the PCM is configured to be heat-exchanged with the coolant heater and the coolant.”

IN BRIEF

• John Curley, former technical sales manager at Conex Bänninger and Viega Ltd., has rejoined Monodraught Ltd. as technical consultant.

• Monodraught, of High Wycombe, United Kingdom, won a Queen’s Award for Enterprise this week for its Cool-phase system, which provides “intelligent control of ventilation and cooling using phase change materials.” Peli BioThermal of Bedfordshire also received a Queen’s Award. The temperature-control packaging company was honored for its “export expertise.”

• Dulas Ltd. has delivered 50 of its VC110SDD solar-powered refrigerators to Pakistan. The 110-liter refrigerators, accredited by the World Health Organization, use paraffin-based phase change material to keep vaccines at temperatures ranging from 5°C to 43°C. Renewable Energy Magazine reports that the U.K. company has also launched a temperature-monitoring device that can record and transmit the performance of the refrigerators in real time at any location in the world.

• Andrew Michler‘s MARTaK Passive House in Colorado has been named the overall winner in Green Builder‘s 10th annual Green Home of the Year Awards. Natural, nontoxic and recycled materials are used throughout the 1,200-square-foot house. Biobased phase change material with a melt point of 23º C is used to help even out temperature spikes. Five hundred square feet of ENRG Blankets made by Phase Change Energy Solutions is installed a south-facing interior wall.

• The agenda has been released for the next Cold Chain Global Forum, set for Sept. 24-27 in Philadelphia. The lineup includes discussions on “CRT Product Solutions: How Can We Use Phase Change Materials or Water-based Refrigerants to Successfully Ship Compliance Ready Materials?” and “How Can We Achieve Sustainability & Environmental Packaging Designs in Temperature Controlled Packaging?” Also on the agenda are sessions on “Improving Sustainability & Environmental Packaging to Reduce Waste and Ensure Temperature Compliant Packaging Designs” and “Maintaining Temperature Control Distribution with New Reduced Delivery Targets” and a master class, “Certification Program: Life-Cycle Development of Temperature Assurance Packaging.”

• Safer Chemicals in Products 2018 will be held in Boston Sept. 17-18. Topics include “Making the Business Case for Safer Chemicals” and “Substitution Strategies in Europe and Canada.”

• New from QY Research: “Temperature Controlled Packaging Solutions Market Size, Share & Trends Analysis Report By Product, By Type, By Region, By Application, Competitive Landscape, And Segment Forecasts 2018-2025“

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Energy:• Experimental validation of an air-PCM storage unit comparing the Effective Heat Capacity and Enthalpy methods through CFD simulations

From Applied Energy:

• Performance enhancement of solar absorption cooling systems using thermal energy storage with phase change materials

From Solar Energy:

• Controlling the heat evaluation of cement slurry system used in natural gas hydrate layer by micro-encapsulated phase change materials

From International Journal of Heat and Mass Transfer:

• Effect of moisture migration and phase change on effective thermal conductivity of porous building materials

From Journal of Cleaner Production:

• Effects of nanoparticle-enhanced phase change material (NPCM) on solar still productivity

From Computational Materials Science:

• Natural convection and solidification of phase-change materials in circular pipes: A SPH approach

From Applied Thermal Engineering:

• Thermal properties and thermal conductivity enhancement of composite phase change material using sodium acetate trihydrate–urea/expanded graphite for radiant floor heating system

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,250 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,250 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcomed Volodymyr Mozol, R&D engineer at Dezega Holding, Ukraine; Christopher Sansom, associate professor in concentrating solar power at Cranfield University, United Kingdom; Udit Mangal, business manager, health care, at Pluss Advanced Technologies, Gurgaon, India; Rex Shen, project manager at Andores New Energy Co. Ltd., Suzhou City, China; Collier Miers, graduate research assistant at Purdue University, Lafayette, Ind.; and Micky Lee, engineer at Oleon in Selangor, Malaysia.