The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

THERMAL ENERGY STORAGE

La Jolla research building makes AIA’s top 10 list of sustainable design

The J. Craig Venter Institute in La Jolla, Calif., is on the American Institute of Architects‘ top 10 list of projects that represent sustainable architecture and ecological design for 2016. The 44,607-square-foot building, the first net-zero biological lab in the world, was designed by ZGF Architects. It uses two 25,000-gallon thermal energy storage tanks — one for warm water, one for cool — to moderate temperatures. Cooling towers chill the TES at night, allowing the building to be cooled during the day without electric chillers. The underground tanks were made by South Gate Engineering of Chino, Calif.

PATENTS

Apparatus for storage, transport and distribution of refrigerated/frozen goods

U.S. patent application 20160109186 (applicant Thermo King Corp., Bloomington, Minn.):

“An apparatus for the storage, transport and distribution of refrigerated or frozen goods, in particular for thermally insulated containers of refrigerated vehicles, cold rooms and the like, including one or more thermal storage devices, each including a housing defining a cavity for holding a phase change material. The cavity contains a heat exchanger that may be supplied with a heat exchange fluid. The housing includes a substantially flat wall portion and a heat transfer enhanced wall portion. The apparatus includes ventilator in communication with the thermal storage device.”

Pressure vessel with PCM and method of use

U.S. patent application 20160109065 (assignee Steelhead Composites LLC, Golden, Colo.):

“The present invention provides a metal-lined composite gas storage device comprising a phase-change material coated on the exterior surface of a metallic liner. The presence of the phase-change material on the exterior surface of the metal liner reduces the temperature change within the interior of the metal liner during a gas filling process compared to a similar vessel that does not have a phase-change material coating, thereby allowing a significantly greater amount of gas to be filled at a given pressure.”

IN BRIEF

• Swedish PCM maker Climator is using ViscoTec‘s 2RD40 Pharma filling pump (cutaway illustration above) to package its salt-based phase change material in tubular bags. ViscoTec, a German company that specializes in packaging equipment for high-viscosity material, says the pump is based on the progressive cavity pump principle and is designed to ensure even distribution of fillers in abrasive fluids.

• The Chalmers University of Technology in Gothenburg, Sweden, is hosting a May 17 workshop on phase change materials for building applications. The all-day event, which includes a university lab tour, is aimed at energy consultants and materials producers. Confirmed participants include representatives of Chalmers, Climator, ZAE Bayern and the KTH Royal Institute of Technology.

• Alaska’s Ketchikan International Airport is switching its heat source to a high-efficiency wood-pellet boiler system with a 1,200-gallon thermal storage tank.

• ASHRAE has proposed guidelines that balance the need for energy conservation and authenticity in the restoration of historic buildings. The guidelines address planning and operation, mechanical systems, building envelopes and lighting.

• Express delivery company TNT has signed up two global customers for its new cold chain packaging and shipping solution, va-Q-tec Ltd.‘s Medpak VI°C, which officially launches this month. One is a clinical trial company; the other is a biotech company.

• In partnership with 3D Systems and the U.S. Department of Energy, the University of Maryland has used the latest 3D printing technology to manufacture a heat exchanger which is said to be 20 percent more efficient than current technology.

• The 2017 Zayed Future Energy Prize competition, which recognizes “significant contributions in the global response to the future of energy,” is now open for entries. Winners are eligible to win up to $1.5 million. This year’s winners included BYD Company Ltd. of China, the world’s largest rechargeable battery supplier; and Kopernik, an Indonesia nonprofit that distributes solar lights, solar home systems, water filters and clean cookstoves in developing countries.

• Puma has unveiled a limited edition, dual-colored TitanTour Ignite Tricks golf shoe, designed to “encourage golfers to have fun, play bold and play loud.” The shoe features Outlast phase change technology to regulate temperature for optimum comfort.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Energy News:• Energy storage for low temperature applications with phase change materials

• High temperature phase change thermal energy storage for concentrating solar power plants

From Energy Conversion and Management:

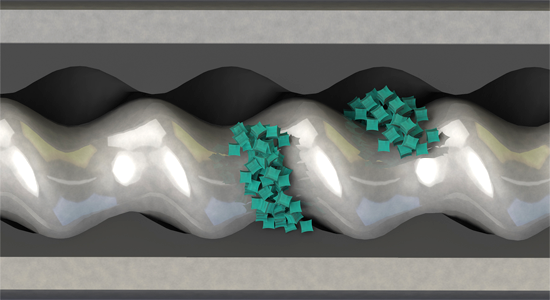

• Morphological control and thermal properties of nanoencapsulated n-octadecane phase change material with organosilica shell materials

From International Journal of Thermal Sciences:

• Experimental investigation of natural convection near a wall containing phase change material

From Energy:

• A newly composed paraffin encapsulated prototype roof structure for efficient thermal management in hot climate

From Energy and Buildings:

• Thermal performance analysis of PCM components heat storage using mechanical ventilation: Experimental results

• Storing surplus solar energy in low temperature thermal storage for refrigeration applications

• Phase Change Materials (PCM) for cooling applications in buildings: A review

From Fluid Phase Equilibria:

• Binary solid–liquid equilibrium systems containing fatty acids, fatty alcohols and trilaurin by differential scanning calorimetry

From Applied Sciences:

• Experimental Evaluation of a Paraffin as Phase Change Material for Thermal Energy Storage in Laboratory Equipment and in a Shell-and-Tube Heat Exchanger

From Journal of Energy Storage:

• Performance evaluation of fatty acids as phase change material for thermal energy storage

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 700 of your peers have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members include Kaushik Mallick, director of engineering at Steelhead Composites, Golden, Colo.; Tuan Ngo, director of the Advanced Protective Technologies for Engineering Structures Group at the University of Melbourne, Australia; Lovelyn Theresa, research scholar at Anna University, Chennai, India; Hongbin (Bill) Ma, LaPierre Professor in Mechanical and Aerospace Engineering, University of Missouri; and James Schenck, vice president of Thermal Battery Systems Inc., Bozeman, Mont. James writes:

“Our company, Thermal Battery Systems, is developing products and services to support Multi-source/hybrid heat pump applications. These applications differ from conventional geothermal heat pump applications in that they are multi source and they actively manage the source side independent of the demand side. I have been very interested in phase change materials for thermal storage for many years and look forward to seeing how others are using them.”

YOUR TURN

Wanted: News tips about PCMs and thermal energy storage

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? We would love to hear from you. Please contact Ben Welter of Entropy Solutions at bwelter@puretemp.com.