The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

ENERGY STORAGE

EnerSTOCK 2018 will feature PCM experts from around the world

The agenda has been posted for the 14th International Energy Storage Conference – EnerSTOCK 2018 – to be held at Cukurova University in Turkey April 25-28. Speakers and topics focusing on phase change material include:

• Mohammed Farid, New Zealand: “Industrial Applications of Energy Storage with Phase Change Materials”

• Zafer Üre, United Kingdom: “Phase Change Material (PCM) Based Energy Storage Materials and Global Application Examples”

• Mónica Delgado, Ana Lázaro, Javier Mazo, Conchita Peñalosa, José María Marín and Belén Zalba, Spain: “Experimental Analysis of a Coiled Stirred Tank Containing a Low Cost PCM Emulsion as Thermal Energy Storage System. Comparison to Other TES Systems”

• Saman Nimali Gunasekara, Monika Ignatowicz, Justin Ningwei Chiu and Viktoria Martin, Sweden: “Thermal Conductivity Measurement of Erythritol, Xylitol and Their Blends for Phase Change Materials Design – A Methodological Study”

• Laura Quant, Gonzalo Diarce, Álvaro Campos-Celador, Ana García-Romero and Jean-Pierre Bédécarrats, Spain: “A Degradation Kinetics and Supercooling Study of the Urea-Sodium Nitrate Eutectic Mixture as a PCM”

• Catarina Araújo, José André Pinheiro and Luís Bragança, Portugal: “Economic Viability, Thermal Comfort and Energy Efficiency of Phase Change Materials Applied in the North of Portugal”

• Gennady Ziskind, Israel: “Modelling Approaches for PCM-Based Storage Systems”

For more information about the conference, contact enerstock2018@cu.edu.tr.

SOFTWARE

Swedish university developing PCM/TES design tool for buildings

Researchers at Chalmers University of Technology in Sweden are developing a design tool for PCM-based thermal energy storage for heating and cooling of buildings.

The project is being conducted by the Division of Building Technology within the university’s Architecture and Civil Engineering Department. Sweden’s Environmental Protection Agency and Energy Agency and the university are jointly funding the effort.

To better understand the needs of potential users of the tool, the research team is inviting professionals in the building sector – such as real estate owners, energy consultants, PCM producers and specifying engineers – to participate in a survey, whether or not they have PCM experience. The survey (https://goo.gl/forms/iEYCD5zIDUlDW5eu1) can be completed in 10 to 15 minutes. Personal data will be kept confidential. Participants who wish to receive the findings of the survey are asked to provide their email address at the end of the questionnaire.

For more information on the project, contact Dr. Nikolaos Stathopoulos, nikstat@chalmers.se.

PATENTS

Low-cost container condition monitor

U.S. patent application 20180080833 (assignee International Business Machines Corp., Armonk, N.Y.):

“Low-cost techniques for sensing ambient temperatures in a container or package using phase change materials are provided. In one aspect, a temperature sensor is provided. The temperature sensor includes: at least one phase change material configured to transition from an amorphous state to a crystalline state upon exposure to temperatures above a predetermined threshold temperature for a given duration. A method of monitoring temperature exposure of a consumer good using the temperature sensor is also provided.”

Vessel assemblies for temperature control

Vessel assemblies for temperature control

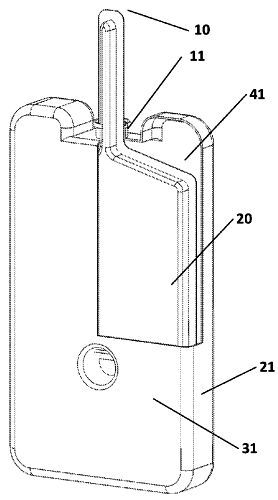

U.S. patent application 20180086534 (applicant American Aerogel Corp., Rochester, N.Y.):

“This present disclosure provides a vessel assembly for use in temperature sensitive shipping that can maintain a payload temperature across a range of temperatures. Importantly, the vessel assembly of the present disclosure reduces the overall packaging materials used in a shipper box and prevents the ‘wrong’ mixture of PCM-containing vessels from being used. … [The vessel assembly comprises] a vessel [21] having a first filling port [11]; and a bladder [20] optionally having a second filling port [10]; wherein the chamber of the vessel comprises a first phase change material; and the bladder comprises a second phase change material.”

Pasteurization for small containers using a phase change material

U.S. patent application 20180092371 (inventors Micaela Langille Collins and Yu-ling Cheng, Toronto, Canada; Scott Nicholas Genin, Unionville, Canada; and Jayesh Kumar Srivastava, West Toronto, Canada):

“A pasteurization device comprising an insulated heating tub, a metal grid heat sink, 69° C. melt-point paraffin wax, wherein the metal grid heat sink and the paraffin wax are combined inside the insulated heating tub; a temperature sensor connected to a microprocessor controlled device, suitable to measure temperature and to generate an alarm, a top plate, and a material suitable to cover the wax; wherein the top plate comprises a plurality of openings corresponding to an opening in the metal grid heat sink of suitable size to accept a baby bottle; wherein the insulated heating tub can be heated to at least 73° C. and wherein the microprocessor controlled device provides an audible tone upon the temperature sensor reading 73° C. for at least 30 seconds.”

Heat storage material

U.S. patent application 20180094180 (applicant Hutchinson SA, Paris, France):

“The invention relates to a material including a support consisting of a porous composite material including at least one polymer phase forming a binder based on at least one polymer selected from thermoplastic polymers, elastomers, and elastomer thermoplastics, and at least one filler selected from thermally conductive fillers, the pores of the support consisting of the porous composite material being partially or entirely filled with at least one phase-change material. The invention also relates to a method for producing said material.”

Battery pack with phase change material

U.S. patent application 20180090728 (applicant LG Chem Ltd., Seoul, South Korea):

“A battery pack according to the present invention comprises a battery cell and a battery case accommodating the battery cell, wherein the battery case comprises an inner case accommodating the battery cell, an outer case disposed outside the inner case, and a cooling member between the inner and outer cases to indirectly cool the battery cell by using cool air generated by cooling the inner and outer cases.”

IN BRIEF

• An artificial-intelligence tool that has digested nearly every chemical reaction ever performed could transform the chemistry world, reports Nature. The tool, developed at the University of Münster in Germany, uses “deep-learning neural networks to imbibe essentially all known single-step organic-chemistry reactions — about 12.4 million of them. This enables it to predict the chemical reactions that can be used in any single step.”

• Pelican BioThermal plans to open a service center in Tokyo next month to service its reusable Credo Cube temperature-control shippers, including refurbishment and repair. The center will also serve as a network station for the company’s Credo on Demand rental program.

• Pelican BioThermal as an opening for “Business Development Manager UK or Netherlands EMEA.”

• Sonoco ThermoSafe has posted the agenda for the company’s first Leading Minds Seminar, to be held June 6-7 in Blue Bell, Pa. Co-hosted by ELPRO, the seminar is a chance for pharmaceutical manufacturers, supply chain partners and government representatives to discuss temperature-assurance packaging and data monitoring in a collaborative environment.

• Va-Q-tec AG of Germany reports that it has received a key European patent for passive pallet-size containers with vacuum insulation panels and phase change materials. The European Patent 2876389 B1, which covers the company’s va-Q-tainer product series, is valid in Germany, United Kingdom, France, Italy, Liechtenstein and Switzerland. “Imitators and competitors will now have to survive without some important thermal and mechanical functions,” said Dr. Joachim Kuhn, the company’s CEO. “The competition seems to be interested in the now legally protected technology and the highly energy efficient containers which are produced from it. We detected that competitors are offering patent infringing products. Obviously, we will take further steps to defend our technology.”

• China’s list of more than 100 U.S. products under threat of tariffs targets the U.S. chemicals and plastics sectors at a time when parts of the industry are investing heavily in new production, CNBC reports. Plastics, petrochemicals, petroleum products and specialty chemicals comprise about 40 percent of the targeted goods.

• New from 360 Market Updates: “Asia Pacific Advanced Phase Change Material Market Analysis 2012-2017 and Forecast 2018-2023“

• Viking Cold Solutions of Houston, Texas, has been named a Top 10 Energy Storage System Provider by Energy CIO Insights. Viking’s PCM-based system is designed to reduce energy consumption in cold storage facilities by 20 to 35 percent.

• Amrit Robbins, CEO and founder of Axiom Exergy, will take part in a panel discussion, “Hot, Cold, and Shocking: What Leading Storage Options Can and Cannot Do,” at the 37th Peak Load Management Alliance Conference in Coronado, Calif., April 16-18.

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Energy and Buildings:• Design and Analysis of PCM Based Radiant Heat Exchanger for Thermal Management of Buildings

• A new ventilated window with PCM heat exchanger – performance analysis and design optimization

• Thermal enhancement of paraffin/hydrophobic expanded perlite granular phase change composite using graphene nanoplatelets

From Energies:

• Thermal Performance of Microencapsulated Phase Change Material (mPCM) in Roof Modules during Daily Operation

From Heat Transfer Engineering:

• Synthesis and Characterization of Thermochemical Storage Material Combining Porous Zeolite and Inorganic Salts

From Renewable Energy:

• Effect of percussion vibration on solidification of supercooled salt hydrate PCM in thermal storage unit

From Applied Energy:

• A review of the applications of phase change materials in cooling, heating and power generation in different temperature ranges

• Energy and exergy efficiencies assessment for a stratified cold thermal energy storage

• Eccentricity optimization of a horizontal shell-and-tube latent-heat thermal energy storage unit based on melting and melting-solidifying performance

From Reactive and Functional Polymers:

• Thiol-yne photo-clickable electrospun phase change materials for thermal energy storage

From Applied Thermal Engineering:

• Investigation of PCM Charging for the Energy Saving of Domestic Hot Water System

From Nano Energy:

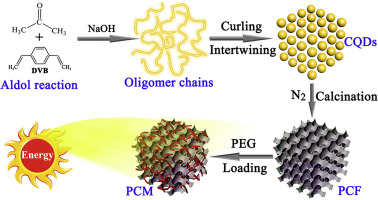

• Highly Graphitized 3D Network Carbon for Shape-stabilized Composite PCMs with Superior Thermal Energy Harvesting

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,200 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,200 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. This week we welcomed Michiel de Bie, product designer at Meds2Go, Noortwijk, Netherlands; John Curley, technical sales manager at Conex Bänninger, Kingswinford, England; Salvatore Vasta, Ph.D. researcher, CNR-ITAE, Catania, Italy; Keri Blackburn, strategic marketing manager at Microtek Laboratories Inc., Dayton, Ohio; and Piet J.J. Kerckhof of Aché Ligno Architects, Aalter, Belgium.

Piet’s first post:

“I’m a Belgian architect and big fan of PCM. We have used it as intelligent inertia in woodframe buildings and as a heat battery for sanitary water.”

Another new member, Robert Craven, wrote:

“I am an R&D engineer at Tennessee Tech University. I have been working with a professor and student to employ phase change material as a thermal bank to heat tomato plant roots in a green house near campus.”