The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

The Phase Change Matters e-mail newsletter is a weekly summary of the latest news and research on phase change materials and thermal energy storage. To subscribe, visit www.puretemp.com/subscribe. For more frequent updates, follow @puretemp on Twitter or visit the Phase Change Matters blog, www.puretemp.com/pcmatters.

PATENTS

ACT is awarded a U.S. patent for PCM with tunable melt point

Advanced Cooling Technologies of Lancaster, Pa., has been awarded a U.S. patent for a phase change material with a tunable melting point.

The hydration level of the PCM, a salt hydrate consisting primarily of salt and water, is altered to change the melting point to a desired set point using changes in humidity of the system.

“In an ARPA-E ARID funded program, we showed that you could change the melting point of salt hydrate phase change materials by changing the hydration levels of the salt hydrate in-situ,” Richard Bonner, right, ACT’s vice president for R&D, wrote in a LinkedIn post. “We also applied this technology to power plant cooling, where the seasonal variations in ambient temperature necessitate different melting points. Congratulations to the inventors: Dr. Ying Zheng, Dr. Chien-hua Chen, Dr. Howard Pearlman, and Dr. Fangyu Cao.”

“In an ARPA-E ARID funded program, we showed that you could change the melting point of salt hydrate phase change materials by changing the hydration levels of the salt hydrate in-situ,” Richard Bonner, right, ACT’s vice president for R&D, wrote in a LinkedIn post. “We also applied this technology to power plant cooling, where the seasonal variations in ambient temperature necessitate different melting points. Congratulations to the inventors: Dr. Ying Zheng, Dr. Chien-hua Chen, Dr. Howard Pearlman, and Dr. Fangyu Cao.”

ACT worked with Lehigh University and the University of Missouri to develop the PCM. The idea was prompted by ACT’s interest in utilizing seasonal shifts in weather for the company’s day/night thermal storage application. A tunable melt point allows the PCM to be more easily solidified in cold and hot seasons.

The targeted melt temperatures in the project were from 25° C to 45° C for low-grade thermal energy storage, but could be extended to higher temperatures with other salt hydrates, the company said.

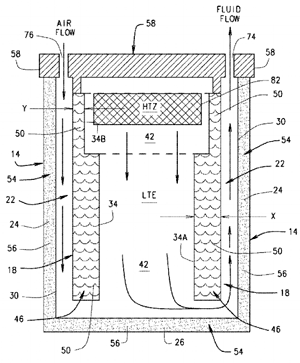

The project was funded, in part, with a $3.2 million ARPA-E ARID grant, awarded in 2015. ARID stands for “Advanced Research in dry Cooling.” The project teams were challenged to “develop innovative, high-performance air-cooled heat exchangers and supplemental cooling systems and/or cool-storage systems” for use in thermoelectric power plants, to replace existing technologies that use a substantial amount of water to cool plant condensers.

The ARID project was completed in 2018. ACT’s invention is now at the lab-scale testing phase. The most difficult hurdle, the company said, will be to scale up to commercialization level. “From a manufacturing standpoint, shifting of the hydration level would require a large infrastructure for altering the humidity,” the company said.

“The concept could also be applied to the HVAC industry (building comfort) to provide day/night load shifting,” the company said, “as well as PCM synthesis and preparation for a consistent product.”

Refrigerator with phase change material

U.S. patent application 20200011583 (applicant LG Electronics Inc., Seoul, South Korea):

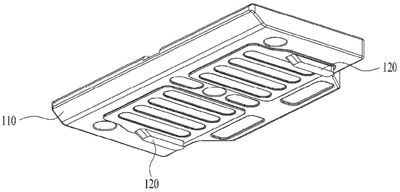

“A refrigerator includes a cabinet, a first inner case that defines a freezing compartment, a second inner case that defines a refrigerating compartment, a thermal siphon unit that is configured to carry a working fluid for heat transfer and that has a closed loop shape that includes a first part arranged at an outer side of the first inner case and a second part arranged at an outer side of the second inner case, and a cool air storage unit arranged in a space partitioned in the first inner case. The cool air storage unit is configured to accommodate cool air of the freezing compartment and transfer the cool air to the first part of the thermal siphon unit arranged outside of the first inner case. … [The] cool air storage unit [shown above] includes a housing that defines an external appearance of the cool air storage unit and that is configured to store a phase change material.”

“A refrigerator includes a cabinet, a first inner case that defines a freezing compartment, a second inner case that defines a refrigerating compartment, a thermal siphon unit that is configured to carry a working fluid for heat transfer and that has a closed loop shape that includes a first part arranged at an outer side of the first inner case and a second part arranged at an outer side of the second inner case, and a cool air storage unit arranged in a space partitioned in the first inner case. The cool air storage unit is configured to accommodate cool air of the freezing compartment and transfer the cool air to the first part of the thermal siphon unit arranged outside of the first inner case. … [The] cool air storage unit [shown above] includes a housing that defines an external appearance of the cool air storage unit and that is configured to store a phase change material.”

Preparation vessel with a cooling device

U.S. patent application 20200009520 (applicant Vorwerk & Co. Interholding GmbH, Wuppertal, Germany):

“A preparation vessel, in particular for a food processor, has a vessel wall and a preparation area surrounded by the vessel wall. The vessel wall has a cooling device that contacts the vessel wall in a heat-conducting manner for cooling a preparation item present in the preparation area. The vessel wall in at least a partial area has a double-walled design, with an inner wall bordering the preparation area and an outer wall that is formed separately from the inner wall and spaced apart from the inner wall by a gap, wherein the gap has the cooling device and a phase change material located between the cooling device and the outer wall as viewed in a direction from the preparation area to the outer wall.”

Drinking container with different temperature zones

U.S. patent application 20200008623 (applicant Curators of the University of Missouri, Columbia, Mo.):

“A drinking container system with multiple temperature zones, wherein the container system includes a main body having a sidewall and a bottom that define a phase change material (PCM) module receptacle, and a phase change material (PCM) module having a sidewall that defines a beverage chamber. The PCM module is disposable within the PCM module receptacle such that a beverage egress flow path is defined between the main body sidewall and the PCM module sidewall. The flow path formed in the container can make the beverage achieve the desired drinking temperature. The PCM module sidewall is at least partially filled with a phase change material and is structured and operable to provide a plurality temperature zones within the beverage chamber. Each temperature zone is operable to maintain a temperature of a respective portion of a liquid disposed within the beverage chamber within a respective temperature range.”

“A drinking container system with multiple temperature zones, wherein the container system includes a main body having a sidewall and a bottom that define a phase change material (PCM) module receptacle, and a phase change material (PCM) module having a sidewall that defines a beverage chamber. The PCM module is disposable within the PCM module receptacle such that a beverage egress flow path is defined between the main body sidewall and the PCM module sidewall. The flow path formed in the container can make the beverage achieve the desired drinking temperature. The PCM module sidewall is at least partially filled with a phase change material and is structured and operable to provide a plurality temperature zones within the beverage chamber. Each temperature zone is operable to maintain a temperature of a respective portion of a liquid disposed within the beverage chamber within a respective temperature range.”

COMPANY NEWS

An anniversary – and a look back

The Phase Change Matters newsletter is celebrating its fifth anniversary with the publication of issue No. 224. Only a handful of folks received issue No. 1; today’s issue will be e-mailed to 1,303 subscribers. More than 40,000 people from more than 160 countries visited puretemp.com last year. Here are the most-viewed newsletter posts from 2019:

1. PureTemp introduces temperature-control fabric coating (Jan. 23)

2. New dorm at Massachusetts college features 18,000+ square feet of PCM mats (Aug. 15)

3. Croda began work on new microencapsulated PCM four years ago (July 26)

4. PCM-equipped infant warming mat set for large-scale trial in Rwanda (Jan. 7)

5. Novel PCM microspheres keep new therapy pack flexible when frozen (June 15)

6. Croda adds 2 biobased phase change materials to its lineup (May 17)

7. PCM system inefficiencies blamed on design flaws, operator errors (March 25)

8. Sunamp signs agreement with Chinese heat pump maker (March 18)

9. PureTemp shows energy-saving potential in EnergyPlus simulations (Aug. 28)

10. Microtek introduces new PCM built with nextek encapsulation technology (March 11)

RESEARCH ROUNDUP

For our full list of recent academic research, see puretemp.com/academic. Here are highlights from the past week:

From Waste Management:• Evaluation of carbonized waste tire for development of novel shape stabilized composite phase change material for thermal energy storage

From Journal of Energy Storage:

• Development of polyurethane foam incorporating phase change material for thermal energy storage

• Facile synthesis and thermal performance of cety palmitate/nickel foam composite phase change materials for thermal energy storage

• Optimal sizing design and operation of electrical and thermal energy storage systems in smart buildings

From Energy Conversion and Management:

• Numerical investigation of the effects of the nano-enhanced phase change materials on the thermal and electrical performance of hybrid PV/thermal systems

• Thermal storage and thermal management properties of a novel ventilated mortar block integrated with phase change material for floor heating: an experimental study

From Applied Energy:

• Wood-based composite phase change materials with self-cleaning superhydrophobic surface for thermal energy storage

From Renewable Energy:

• Corrosion assessment of promising hydrated salts as sorption materials for thermal energy storage systems

• Experimental study on latent thermal energy storage system with gradient porosity copper foam for mid-temperature solar energy application

• Selection of a phase change material and its thickness for application in walls of buildings for solar-assisted steam curing of precast concrete

• Experimental assessment of Phase Change Material (PCM) embedded bricks for passive conditioning in buildings

From Applied Thermal Engineering:

• Analysis of energy retrofit system using latent heat storage materials applied to residential buildings considering climate impacts

• Experimental and numerical simulation of phase change process for paraffin/expanded graphite/ethylene-vinyl acetate ternary composite

• An experimental investigation on the evaporation of polystyrene encapsulated phase change composite material based nanofluids

From Solar Energy Materials and Solar Cells:

• Lightweight mesoporous carbon fibers with interconnected graphitic walls for supports of form-stable phase change materials with enhanced thermal conductivity

From Energies:

• The Effects of Fin Parameters on the Solidification of PCMs in a Fin-Enhanced Thermal Energy Storage System

From Journal of Materials Science:

• Graphene aerogel-based phase changing composites for thermal energy storage systems

From Journal of Mechanical Science and Technology:

• A study on development of the thermal storage type plate heat exchanger including PCM layer

From Journal of Power Sources:

• Delayed liquid cooling strategy with phase change material to achieve high temperature uniformity of Li-ion battery under high-rate discharge

From Scientific Reports:

• Modification of asphalt mixtures for cold regions using microencapsulated phase change materials

From ASES National Solar Conference:

• A Study on the Thermal Energy Storage System Using Multiple PCMs [pdf]

From Molecules:

• Assessment of Thermal Performance of Textile Materials Modified with PCM Microcapsules Using Combination of DSC and Infrared Thermography Methods

From Energy and Buildings:

• Experimental study on thermal performance of a mobilized thermal energy storage system: A case study of hydrated salt latent heat storage

From Chemical Engineering Journal:

• Shape-stabilized hydrated salt/paraffin composite phase change materials for advanced thermal energy storage and management

From International Journal of Heat and Mass Transfer:

• A conjugate heat transfer model for unconstrained melting of macroencapsulated phase change materials subjected to external convection

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,500 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

More than 1,500 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. The Phase Change Matters group is an interactive complement to the award-winning blog and newsletter of the same name.

You are invited to join the group and connect with PCM and TES experts from around the world. New members this month include Dr. Stefan Busse-Gerstengarbe, project manager at Forschungszentrum Jülich GmbH, Germany; Adeel Arshad, research scholar at Fluids & Thermal Engineering research group (FLUTE), Nottingham, United Kingdom; Enes Savli, research and development specialist at Mir Arge, Istanbul, Turkey; and Bhanu Verma, senior associate at Pluss Advanced Technologies Pvt. Ltd., Gurugram, India.